Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

A technology of isocyanate and diisocyanate, applied in the field of isocyanate derivatives, can solve the problem of low extreme pressure and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

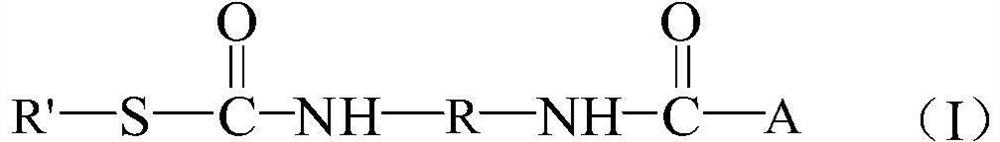

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] First, add 10.44g of n-stearyl mercaptan and 0.1g of triethylenediamine into 30g of 500N base oil to dissolve, add 4.56g of MDI into 30g of 500N base oil to dissolve, then slowly add into the base oil in which n-stearyl mercaptan is dissolved, and keep The temperature was stirred at 80° C. for 1 h. Continue to raise the temperature to 185° C., keep it warm for 15 minutes, cool down, and grind to obtain a grease composition. The physical and chemical properties of the resulting grease composition are shown in Table 1.

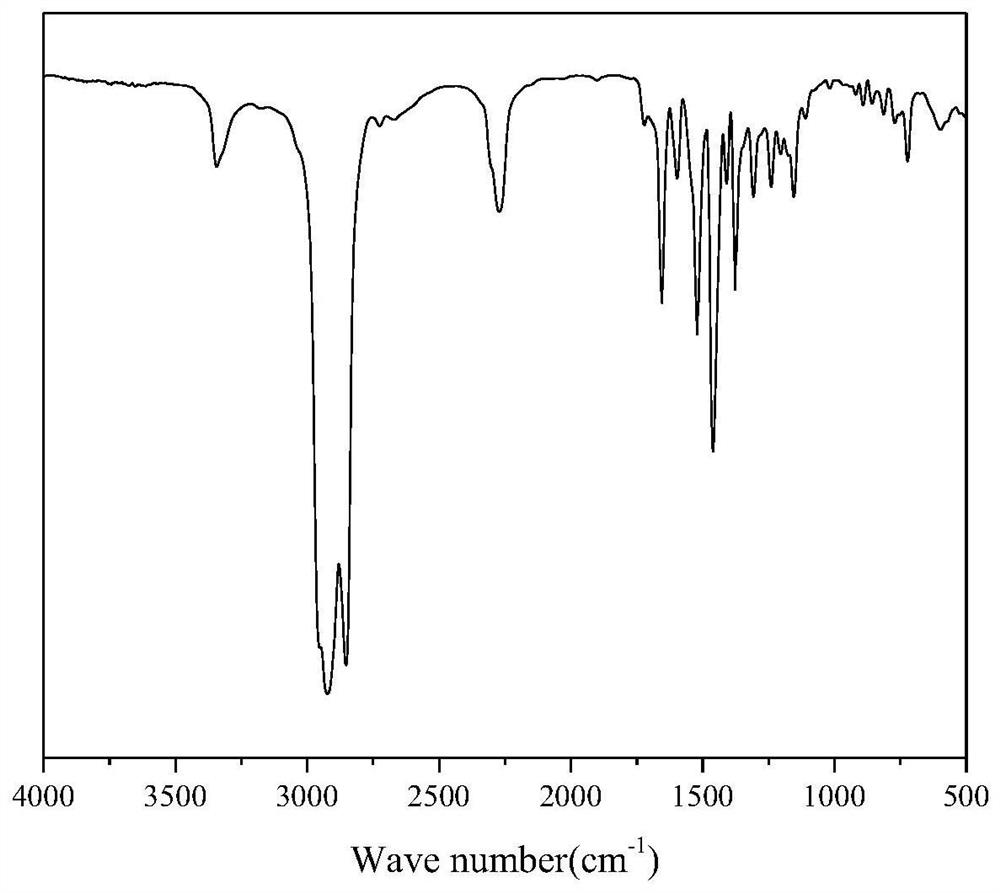

[0045] Utilize petroleum ether to dissolve the described grease composition, and through ultrasonic dispersion, centrifuge to remove the lubricating oil base oil in the described grease composition, obtain the isocyanate derivative of the present invention, carry out infrared spectrogram test to it, spectrogram sees figure 1 . As can be seen from the figure, the 3300cm -1 The left and right peaks are the stretching vibration absorption peaks of -NH- in...

Embodiment 2

[0047] First add 4.66g of MDI to 30g of 500N base oil to dissolve, add 5.01g of octadecyl primary amine to 15g of 500N base oil to dissolve, and then slowly add it dropwise to the base oil in which MDI is dissolved under sufficient stirring conditions, keeping the temperature Fully stir the reaction at 70°C for 30min, then slowly add dropwise a mixture of 5.33g n-octadecanethiol and 0.1g triethylenediamine dissolved in 15g 500N base oil, keep the temperature at 80°C and stir the reaction for 1h, and continue to heat up to 185° C., heat preservation for 15 minutes, cooling, and grinding to obtain a grease composition. The physical and chemical properties of the resulting grease composition are shown in Table 1.

Embodiment 3

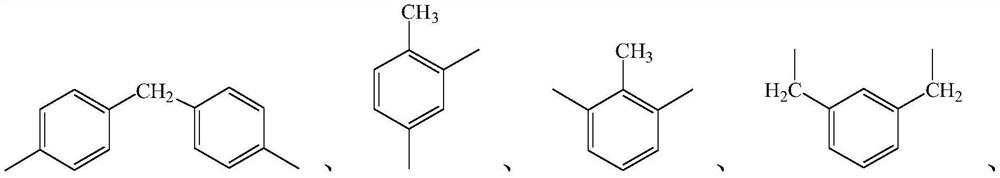

[0049] First add 5.82g MDI to 30g 500N base oil to dissolve, add 2.50g p-toluidine to 15g 500N base oil to dissolve, then slowly add dropwise to the base oil in which MDI is dissolved and keep the temperature at 70°C under sufficient stirring conditions Fully stir the reaction for 30 minutes, then slowly add dropwise a mixture of 6.68g n-octadecylmercaptan and 0.1g triethylenediamine dissolved in 15g 500N base oil, keep the temperature at 80°C and fully stir the reaction for 1h, continue to heat up to 185°C, Insulated for 15 minutes, cooled, and ground to obtain a grease composition. The physical and chemical properties of the resulting grease composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com