Semiconductor element overturning equipment

A technology of flipping equipment and semiconductors, applied in conveyor objects, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem that the cleanliness level does not meet higher requirements, the accuracy of the construction period cannot be guaranteed, and the processing and transportation cycle can be extended. problems, to achieve the effect of saving labor costs, ensuring stability, and smooth transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

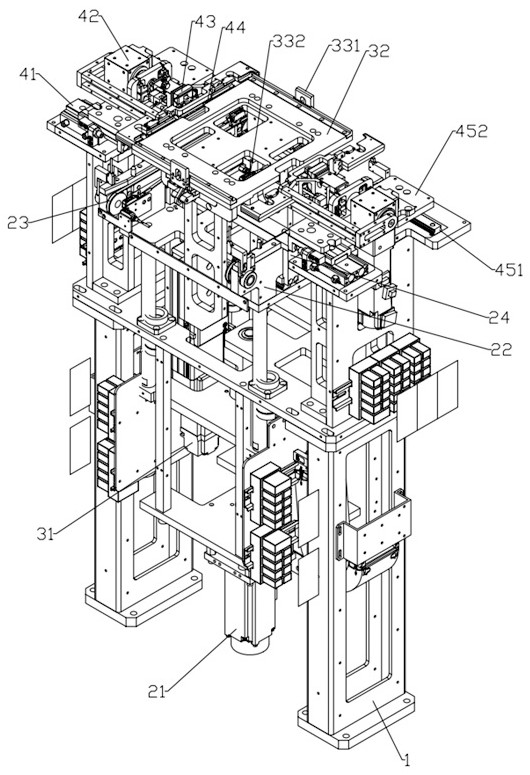

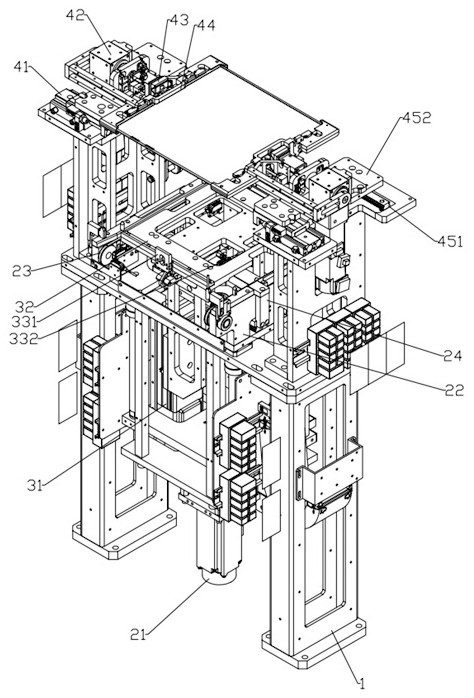

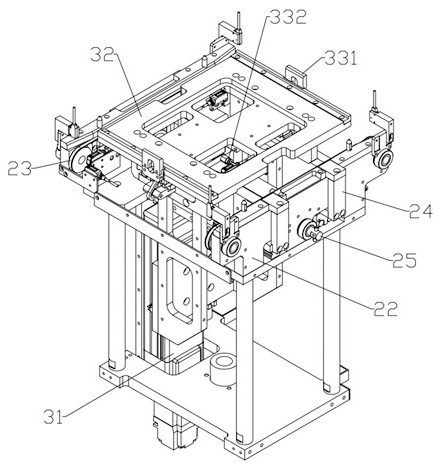

[0042] First, combine the Figure 1~6 The semiconductor component flipping device according to the embodiment of the present invention is described, which is used to transfer semiconductor components (such as wafers, PCB boards, etc.) and flip the transferred workpieces, and has a wide range of application scenarios.

[0043] like Figure 1~6 As shown, the semiconductor element flipping device according to the embodiment of the present invention has a frame body 1 , a loading and unloading module, a jacking module and a flipping module.

[0044] Specifically, such as Figure 1~2 As shown, in this embodiment, the loading and unloading module is connected with the frame body 1 for loading and unloading external workpieces, the jacking module is connected with the loading and unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com