Sponge short foam storage device

A sponge and storage technology, which is applied in storage devices, packaging recycling, transportation and packaging, etc., to achieve the effects of preventing slipping, fast access, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

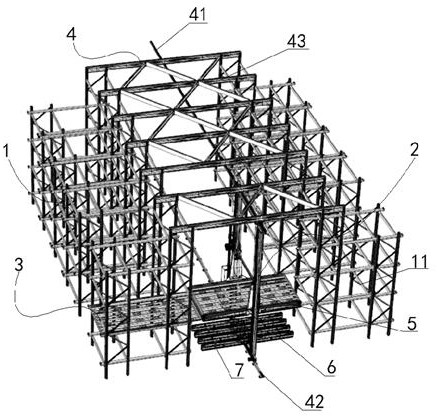

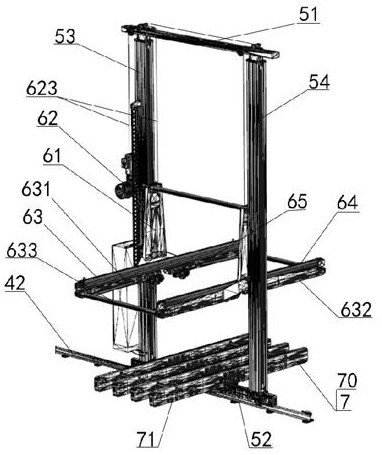

[0030] Refer to attached Figure 1-15 , a short foam storage device for sponges, which includes a storage shelf 1, a sponge access mechanism 2 and a sponge tray 3, the storage shelf 1 is designed with a number of storage locations 11 for storing short foams, and the storage The mechanism 2 is used to put the sponge tray 3 into the corresponding warehouse position 11 or take it out from the corresponding warehouse position 11 in sequence; / unloading platform 7, the door frame 5 is movably installed on one side of the storage shelf 1 through the guide rail mechanism 4, the lifting platform 6 can be lifted up and down and installed between the door frames 5, and the loading / unloading platform 7 is installed on The inner lower end of the portal frame 5 .

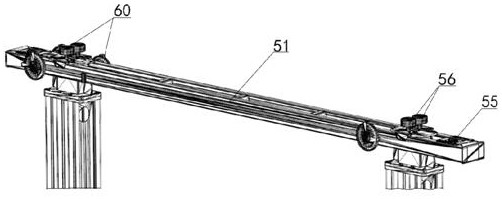

[0031] Such as figure 1 , the guide rail mechanism 4 includes an upper track 41 and a lower track 42, the upper end of the upper track 41 is installed under the cross frame 43, and one side or both sides of the cross frame 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com