Moisturizing composition and application

A technology of composition and extract, applied in the field of composition, can solve problems such as ignorance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

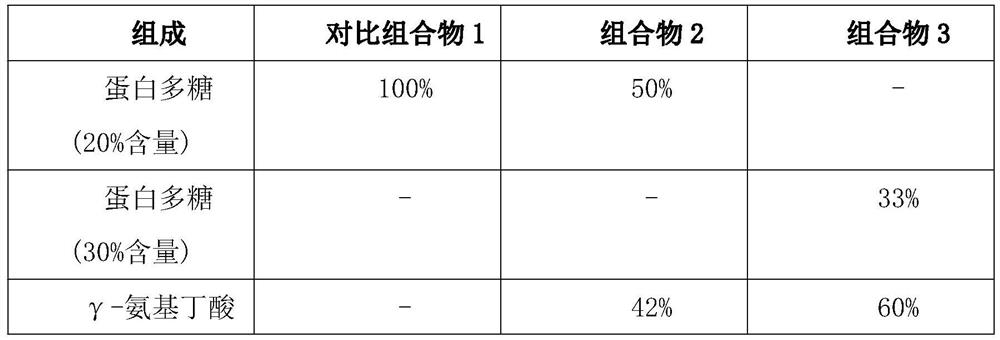

[0031] The formula of embodiment 1 composition

[0032]

[0033]

[0034] Raw material source: Raw proteoglycan was purchased from API Co., Ltd. BlueJuve TM Brand proteoglycan, its content is 20% and 30% respectively. The raw material γ-aminobutyric acid (≥95%) was purchased from Nantong Licheng Bioengineering Co., Ltd., and the raw material kiwifruit seed extract was purchased from Oryza Oil & Fat Chemical Co., Ltd.

Embodiment 2

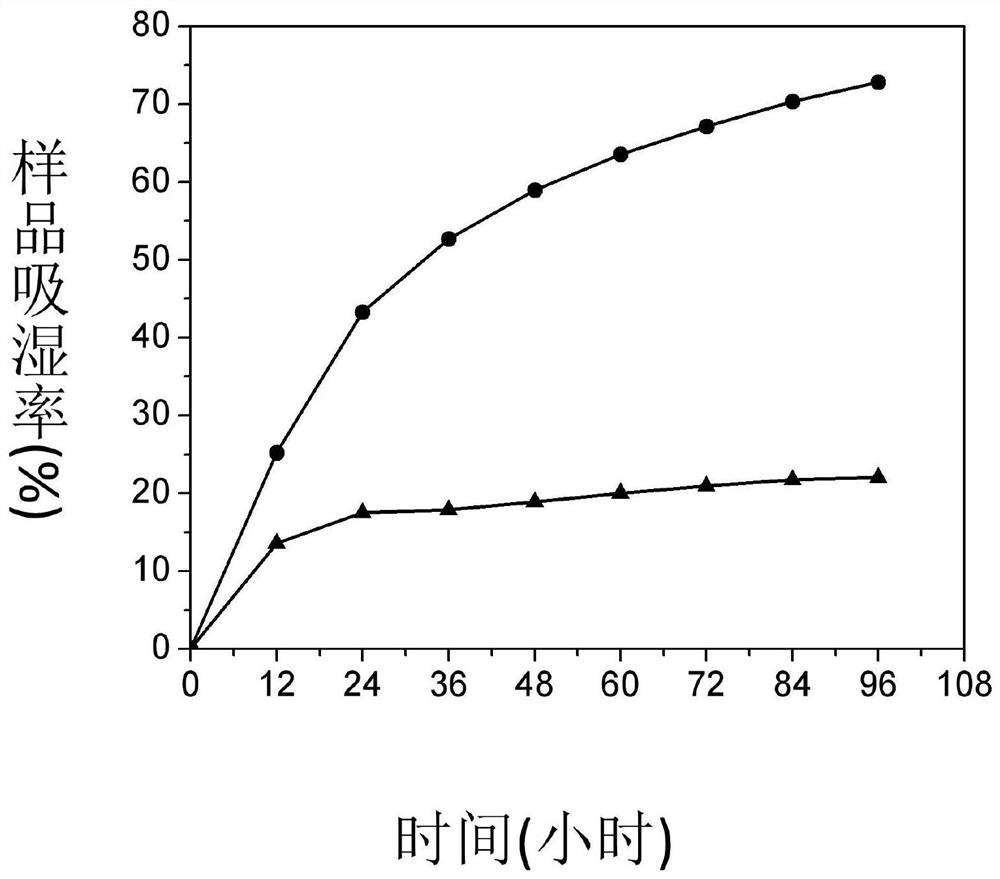

[0035] Embodiment 2 moisturizing effect detection

[0036] Moisture absorption and retention capabilities were tested according to the method explained by Shao et al. (Int. J. Biol. Macromol. 72 (2015) 924-930.). The samples were completely dried in the oven for 4 hours. The dried polysaccharides and control glycerol were then kept in an incubator at 23±1°C with a relative humidity of 97±2%. The water absorption capacity is calculated by the percent weight gain in the dried sample. The weight of the samples was measured after 0, 12, 24, 36, 48, 60, 72, 84 and 96 hours. Wh represents the weight of the sample after h hours; W0 represents the weight of the sample before the start of the experiment.

[0037] Moisture absorption rate (%)=(Wh-W0) / W0x 100%

[0038] The results are summarized in Table 1

[0039] t / h Moisture absorption rate of composition 2 (%) Moisture absorption rate (%) of comparative composition 1 0 0 0 3 8.645987198 8.242245 6 ...

Embodiment 3

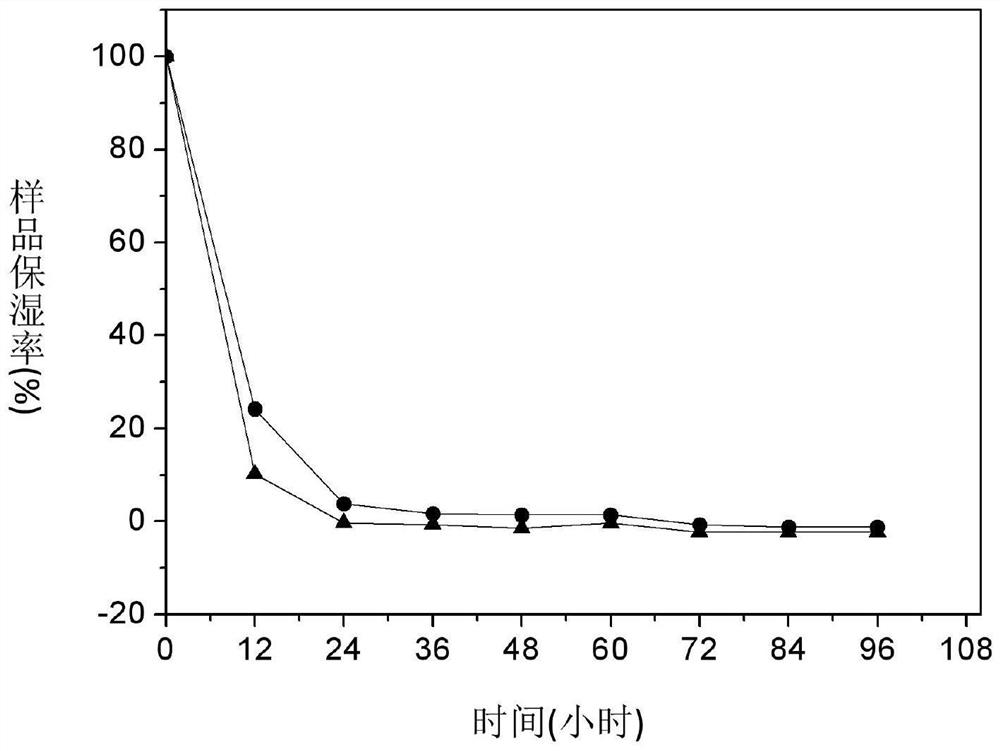

[0042] Embodiment 3 Moisture retention test

[0043] For the moisture retention test, 100% water was added to 100 mg of the vacuum oven dried sample to prepare a wet sample. The prepared wet samples were stored in a closed room with a relative humidity of 10% to 30% by using color-changing silicone at 23.8±2°C. Water retention capacity was estimated by the percentage of residual water in the wet sample by measuring after 0, 12, 24, 36, 48, 60, 72, 84 and 96 hours.

[0044] Moisture retention rate (%) = Wn / W0x 100%

[0045] where W0 and Wn are the weight of the sample before and after the moisture is kept in the room for n hours

[0046] The results are summarized in Table 2

[0047] time Moisture retention rate of composition 2 (%) Moisture retention rate (%) of comparative composition 1 0h 100 100 12h 24.1622575 10.26339691 24h 3.791887125 -0.272479564 36h 1.675485009 -0.726612171 48h 1.410934744 -1.36239782 60h 1.410934744 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com