Step-up DC converter startup control method, device and switching power supply

A DC converter and step-up technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, control/regulation system, etc., can solve the problem of exceeding the safety range of current and affecting circuit reliability and safety , inductor current overshoot and other issues, to avoid the continuous increase of inductor current, improve circuit safety and reliability, and solve the effect of current overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first embodiment of the present invention provides a start-up control method for a boost-type DC converter. This embodiment can be applied to an application scenario where segmented control is performed at the start-up stage of a boost-type DC converter. The method can be controlled by the start-up The starting control device can be implemented in the form of hardware and / or software, and the starting control device can be configured in the control module of the switching power supply.

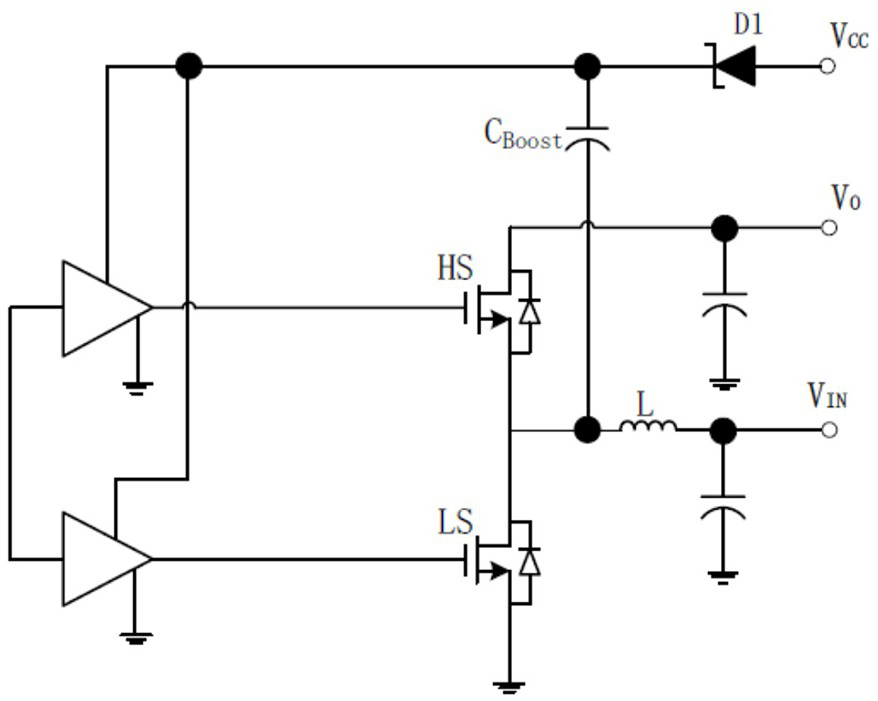

[0029] Incorporate references figure 1 shown, the boost DC converter is provided with a bootstrap capacitor C Boost , the upper power tube HS, the lower power tube LS and the inductor L, when the lower power tube LS is turned on, the charging loop of the bootstrap capacitor is turned on.

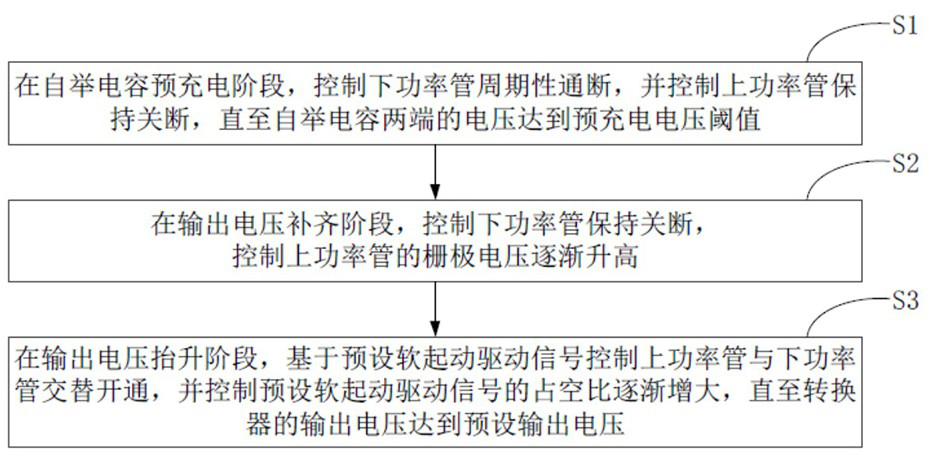

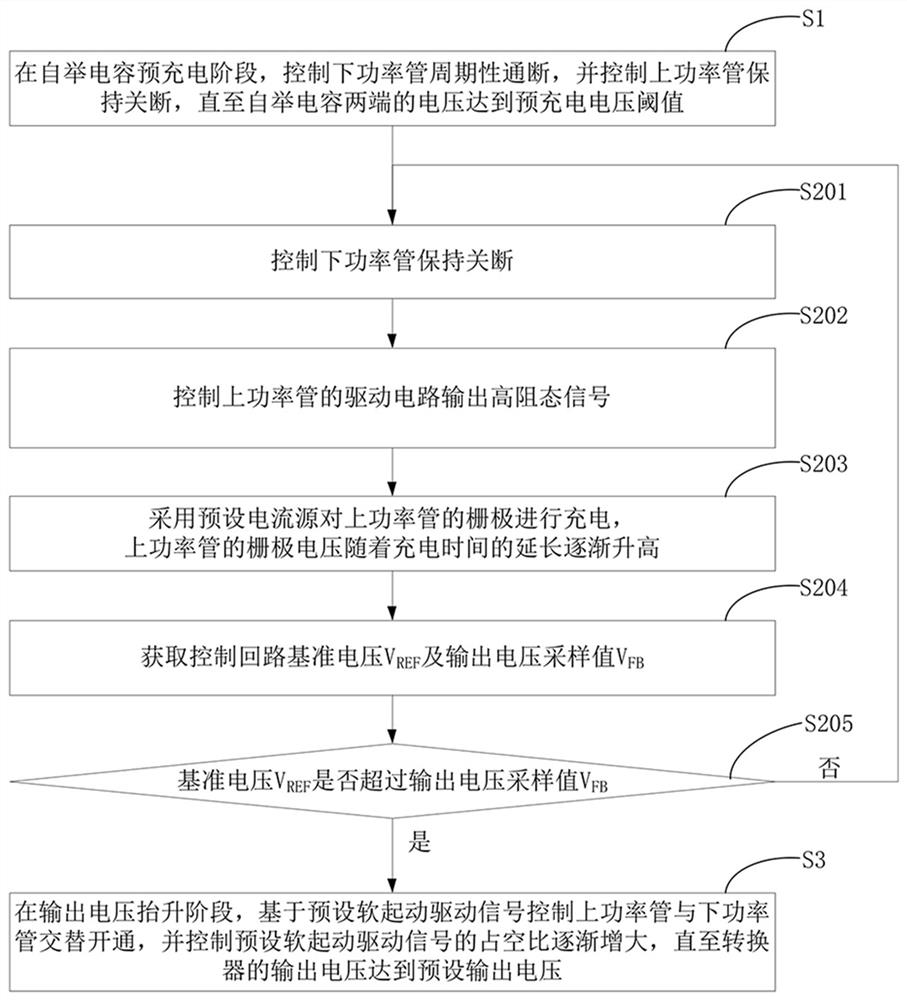

[0030] In this embodiment, the step-up DC converter startup control method includes: a bootstrap capacitor precharging stage, an output voltage complementing stage, and an output voltage boosting...

Embodiment 2

[0080] Based on the above-mentioned embodiments, the second embodiment of the present invention provides a step-up DC converter startup control device. The startup control device provided in the embodiment of the present invention can execute the startup control method provided by any embodiment of the present invention, and has the ability to execute Corresponding functional modules and beneficial effects of the method. The method includes: a bootstrap capacitor precharging stage, an output voltage compensating stage and an output voltage boosting stage, which are performed in sequence.

[0081] Incorporate references figure 1 shown, the boost DC converter has a bootstrap capacitor C Boost , the upper power tube HS, the lower power tube LS and the inductor L, when the lower power tube LS is turned on, the bootstrap capacitor C Boost The charging circuit is turned on.

[0082] Image 6 This is a schematic structural diagram of a start-up control device for a boost-type DC ...

Embodiment 3

[0090] Based on the above embodiment, Figure 7 It is a schematic structural diagram of a switching power supply provided in Embodiment 3 of the present invention.

[0091] like Figure 7 As shown, the switching power supply 1 includes the above-mentioned step-up DC converter start-up control device 00 .

[0092] In this embodiment, the switching power supply 1 may be a boost-type DC converter, or a switching device provided with a boost-type DC converter.

[0093] The switching power supply provided by the embodiment of the present invention is provided with a start-up control device, and the device executes a start-up control method. In the pre-charging stage, the lower power tube is controlled to be turned on and off periodically, and the upper power tube is controlled to be kept turned off until the voltage across the bootstrap capacitor reaches the pre-charge voltage threshold. ;In the output voltage compensation stage, the power tube under control is kept off, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com