Electrode plate, electrochemical device and electronic equipment

An electrode pole piece and tab technology, which is applied to electrochemical generators, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problem of large thickness of the tab connecting piece, low utilization rate of the internal space of the lithium ion battery, and easy bending. Problems such as breakage occur, to reduce charging time, improve space utilization, and be less prone to breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 11

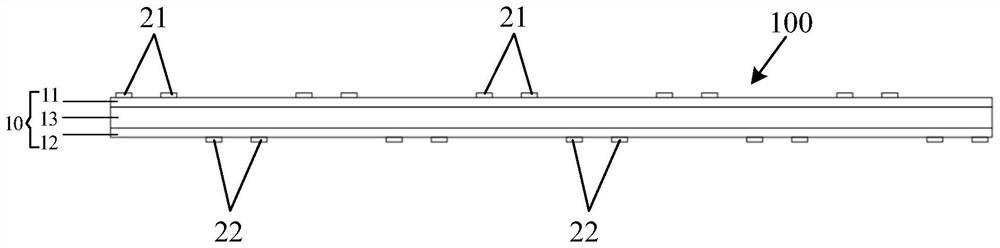

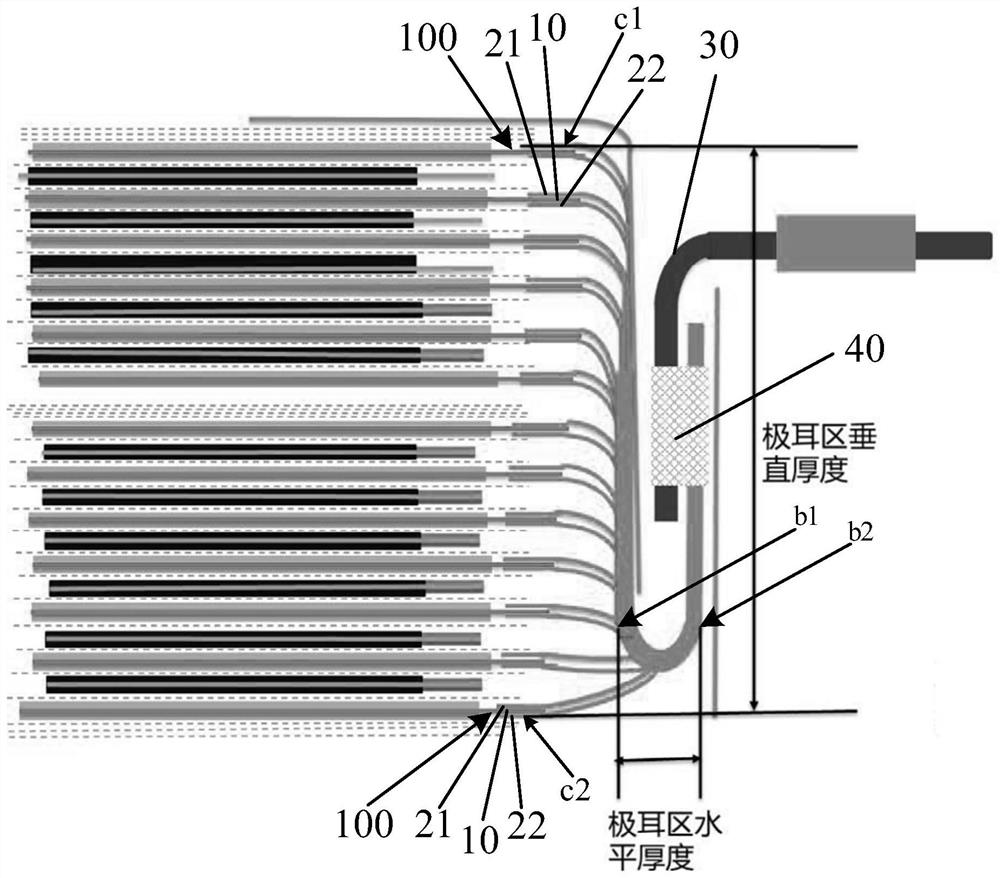

[0076] In this experimental example 1.1, the electrode pole piece has a total of 20 tab connection pieces (aluminum foil with a thickness of 10 μm, including 10 first tab connection pieces and 10 second tab connection pieces). The projections of the 10 first lug connecting pieces on the polymer layer and the projections of the 10 second lug connecting pieces on the polymer layer are equidistantly distributed (the equidistant distance is 10mm), and the first conductive layer has 5 groups A set of lug connecting pieces (2 first lug connecting pieces in each group), a total of 5 sets of second lug connecting pieces in the second conductive layer (2 second lug connecting pieces in each group), 5 first The projections of the tab connecting sheet group on the polymer layer and the projections of the five second tab connecting sheet groups on the polymer layer are alternately distributed. The electrode pads in Experimental Example 1.1 can refer to figure 1 The schematic structure o...

experiment example 12

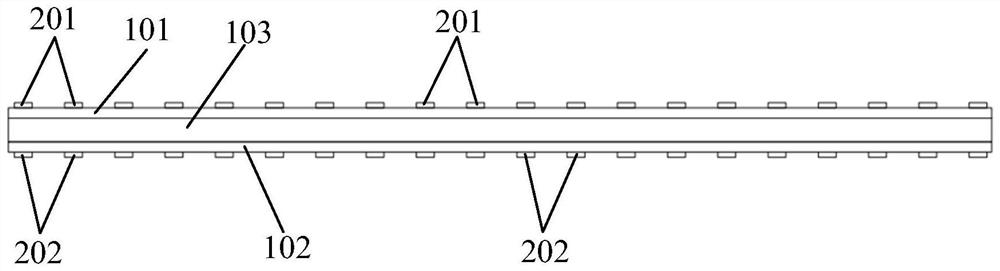

[0081] In this experimental example 1.2, the electrode pole piece has a total of 20 tab connection pieces (aluminum foil with a thickness of 10 μm, including 10 first tab connection pieces and 10 second tab connection pieces). The projections of the 10 first lug connecting pieces on the polymer layer and the projections of the 10 second lug connecting pieces on the polymer layer are equidistantly distributed (the equidistant distance is 10mm), and there are 10 groups of the first conductive layer. One lug connecting sheet group (1 first lug connecting piece per group), 10 sets of second tab connecting piece groups (1 second lug connecting piece per group), 1 first The projection of the tab connecting sheet group on the polymer layer and the projection of a second tab connecting sheet group on the polymer layer are alternately distributed. The electrode pads in Experimental Example 1.2 can refer to Figure 5 The schematic structure of the electrode pad 100 is understood.

[...

experiment example 13

[0086] In this experimental example 1.3, the electrode pole piece has a total of 20 tab connection pieces (aluminum foil with a thickness of 10 μm, including 10 first tab connection pieces and 10 second tab connection pieces). The projections of the 10 first lug connecting pieces on the polymer layer are equidistantly distributed with the 10 second lug connecting pieces (the equidistant distance is 10mm), and the first conductive layer has 4 sets of first lug connecting piece groups ( 3 first lug connecting pieces in each group), 4 sets of second lug connecting pieces in total in the second conductive layer (2 second lug connecting pieces in each group), 4 first lug connecting piece groups are aggregated The projections on the object layer and the projections of the four second lug connecting sheet groups on the polymer layer are alternately distributed. The electrode pads in Experimental Example 1.3 can refer to Figure 6 The schematic structure of the electrode pad 100 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com