Device and method for verifying aircraft engine nacelle pressure relief system

An aircraft engine and nacelle technology, which is applied in the field of devices for verifying the nacelle pressure relief system of an aircraft engine, can solve the problem that the pressure relief performance of the nacelle pressure relief system cannot meet the requirements, the working pressure and temperature of the aeroengine are low, and the nacelle pressure relief To avoid problems such as the increase of system emissions, to avoid distortion of experimental data, improve reliability, and stabilize the test environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

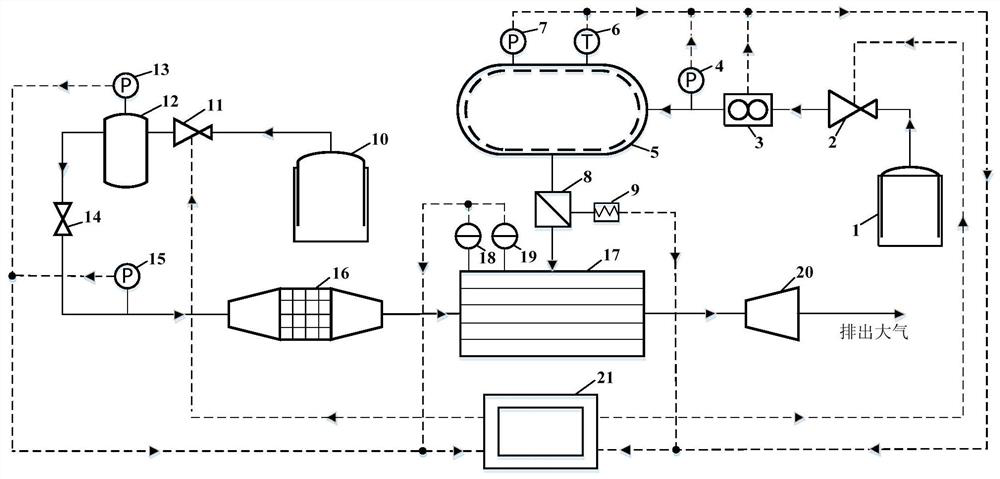

[0053] Such as figure 1 as shown, figure 1 It is a schematic diagram of the experimental bench for testing the pressure relief performance of the aircraft engine nacelle pressure relief system of the present invention, including a pipeline leakage subsystem, a pressure relief door discharge subsystem, a flight environment simulation subsystem and a measurement and control subsystem; the measurement and control subsystem controls The operation of pipeline leakage subsystem, pressure relief door discharge subsystem, and flight environment simulation subsystem. The pipeline leakage subsystem is used to simulate the leakage of the high-pressure bleed air pipeline inside the nacelle. The pressure relief door discharge subsystem is used for the pressure relief process of the nacelle pressure relief system and to obtain the pressure change inside the nacelle. The flight environment simulation subsystem is used to simulate the flight environment at the flight altitude and Mach numbe...

Embodiment 2

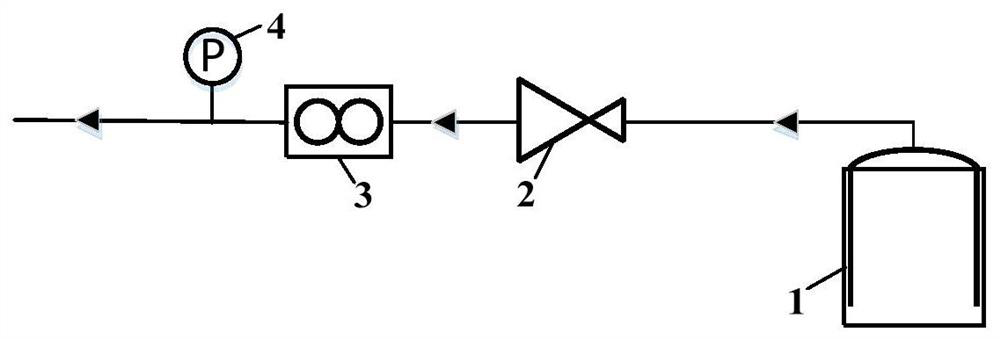

[0061] Such as figure 2 as shown, figure 2 It is the pipeline leakage subsystem of the present invention, which is used to simulate the leakage of the high-pressure bleed air pipeline inside the nacelle, wherein the first gas source 1, the first pressure reducing valve 2 connected in sequence with the first gas source 1, the mass flow rate Meter 3, the first pressure sensor 4 can produce leakage gas with stable pressure and flow rate;

Embodiment 3

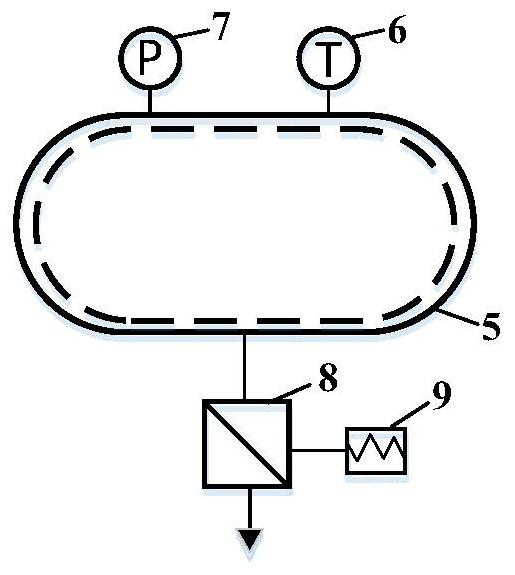

[0063] Such as image 3 as shown, image 3 It is the discharge subsystem of the pressure relief door of the present invention, which is used for the pressure relief process of the nacelle pressure relief system and obtains the pressure change inside the nacelle. When the system is running, the outlet of the nacelle 5 is connected with the pressure relief door 8, and the first temperature The probe of the sensor 6 is arranged in the nacelle 5 for sensing the gas temperature in the nacelle 5; the probe of the second pressure sensor 7 is arranged in the nacelle 5 for sensing the gas pressure in the nacelle 5; attitude The sensor 9 is arranged on the surface of the pressure relief door 8, and is used to sense the posture change of the pressure relief door 8;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com