Actuator cylinder device with rotatable connector

A technology for actuators and rotary joints, which is applied in the fields of aviation and machinery, can solve problems such as installation stress, and achieve the effects of reducing installation stress, good versatility, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

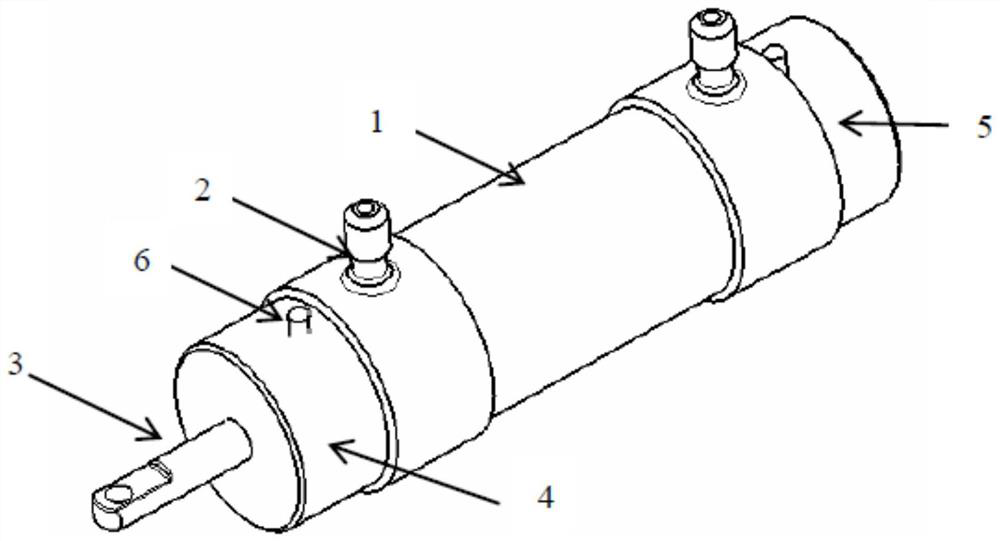

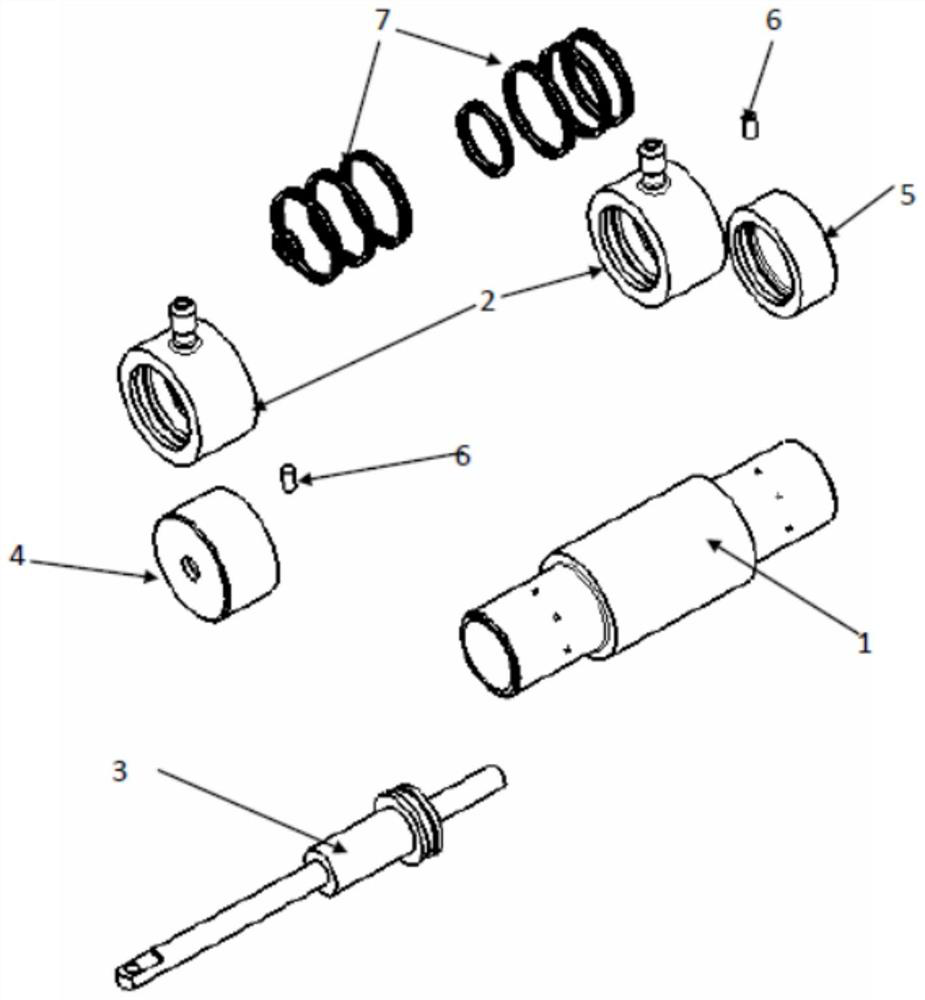

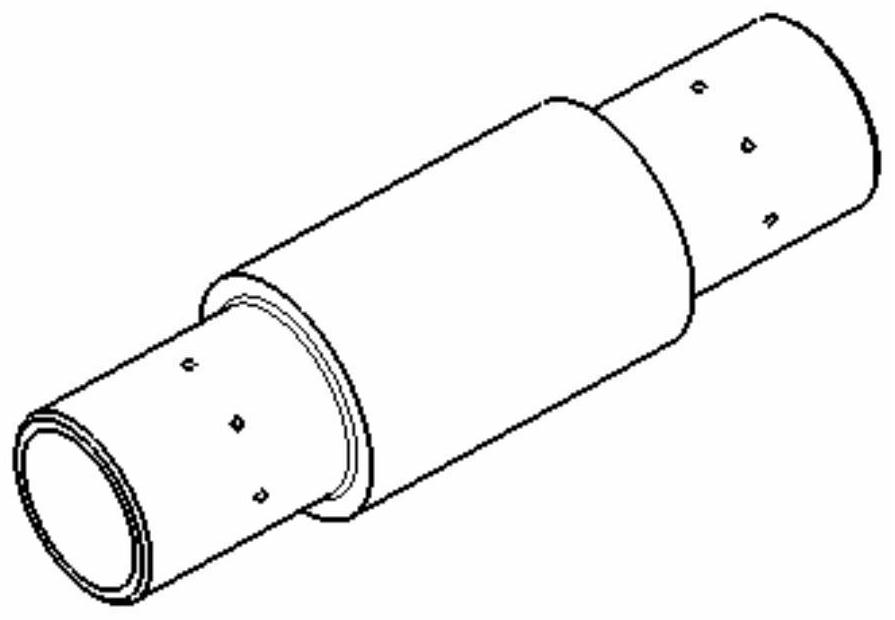

[0028] Such as figure 1 , 2 As shown in and 8, the joint rotatable actuator device of the present invention consists of an outer cylinder 1 with an oil through hole, a rotary joint 2 with a sealing groove, a piston rod 3, a front end cover 4, a rear end cover 5, a locking Composed of screws 6, retaining rings and seals 7 (multiple seals);

[0029] The cylinder device of the present invention is equipped with two rotary joints 2 on the outer cylinder 1 with oil passage holes, the piston rod 3 passes through the central through hole of the front end cover 4, and the front end cover 4 is installed on the outer cylinder 1 with oil passage holes. The front end, the rear end cover 5 is installed in the rear end of the urceolus 1 with the oil through hole. The bosses on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com