Combined heavy machine tool foundation settlement precision detection device

A combined foundation and foundation settlement technology, which is applied in the field of combined heavy-duty machine tool foundation settlement precision detection devices, can solve the problems of waste of embedded sensor resources and long detection accuracy of a single sensor, so as to improve detection accuracy and reduce linear The effect of degree problem and installation stress, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

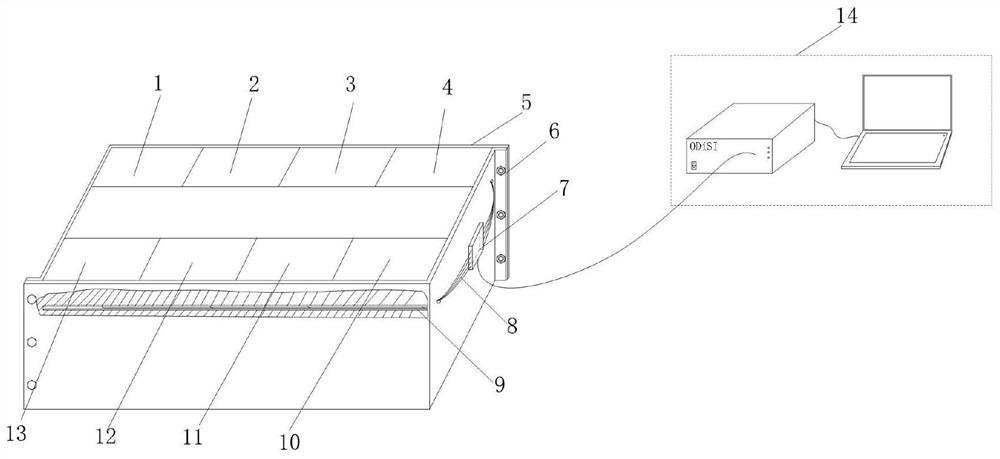

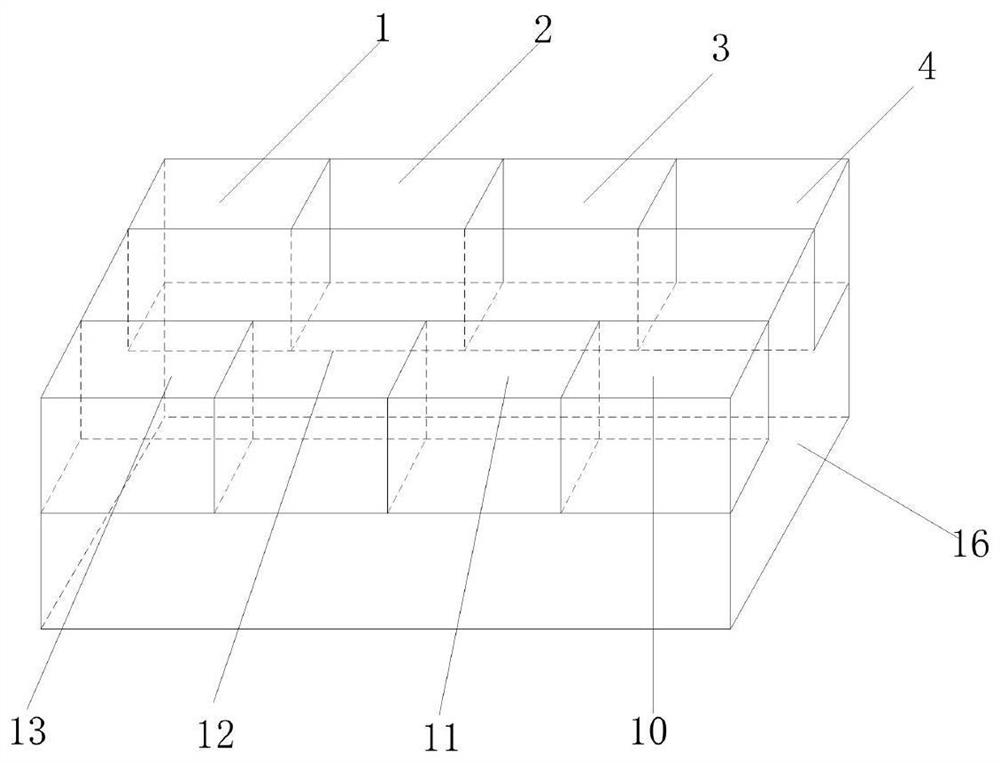

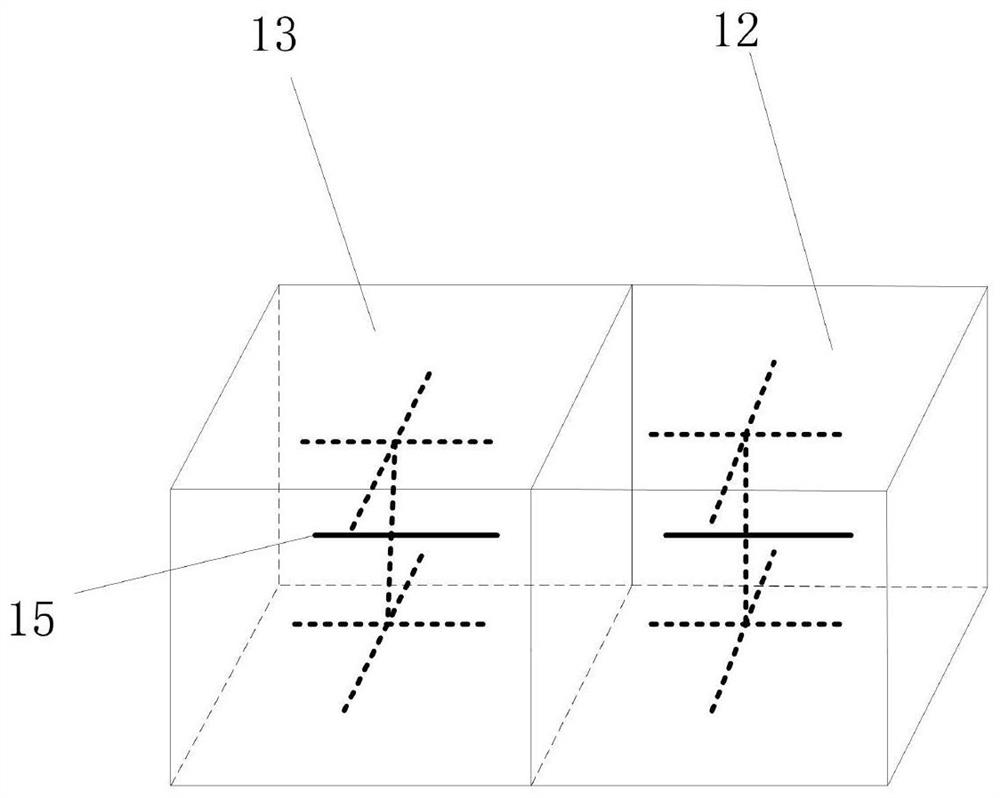

[0016] like Figure 1~3 Shown is a combined heavy-duty machine tool foundation settlement precision detection device.

[0017] Determine the size of the machine tool foundation according to the established machine tool scale ratio. Referring to the topological structure and force characteristics of the machine tool, choose to arrange the fiber optic sensor at the position of the basic control guide rail. In order to realize the replacement of the damaged sensor, the foundation of each side is designed in combination, which can be determined according to the actual situation. Here, it is divided into four sub-blocks as an example, and the length of each sub-block is equivalent. The four sides of the combined foundation are fixed with an adjustable foundation box 5. By adjusting the tightness of the adjusting nut 6, the rigidity of the foundation block is ensured. A single combined foundation sub-block ensures the roughness of the contact surface to ensure full contact and avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com