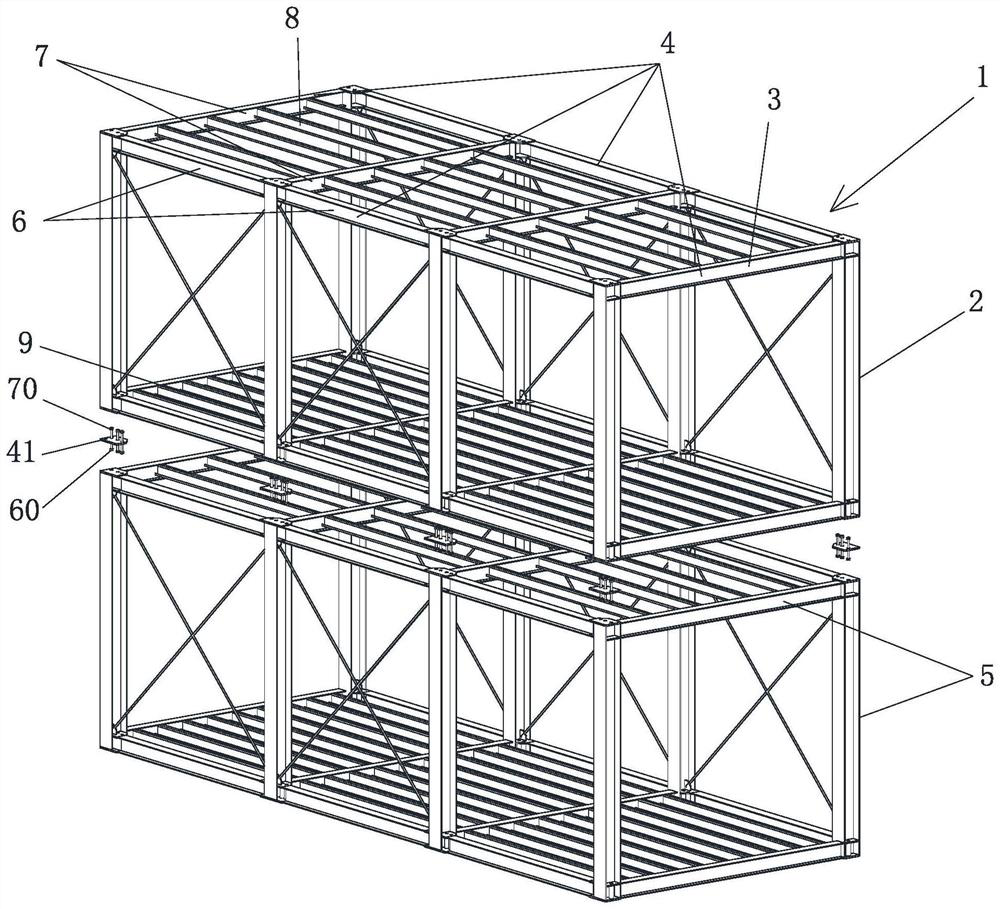

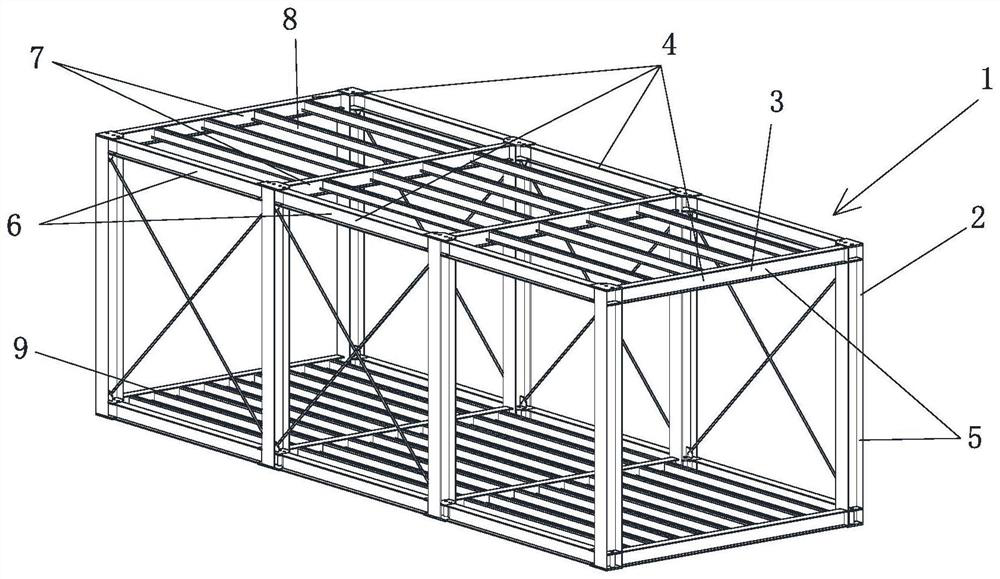

Steel beam column module building structure system and construction method thereof

A technology for building structures and steel beams and columns, which is applied in the direction of building construction, construction, and building material processing, and can solve problems such as waste of materials, complicated construction procedures, and unfavorable bolt installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

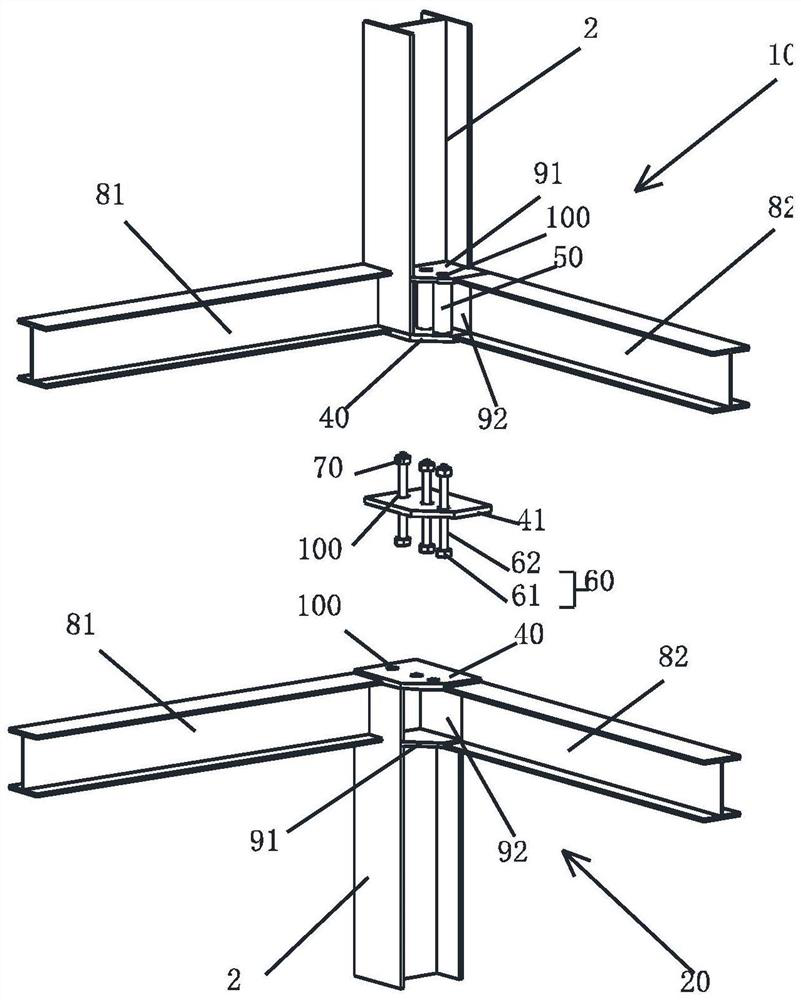

[0072] see Figure 3-Figure 5 , the casing 50 in this embodiment includes a cylindrical casing welded to the H-shaped steel beam-column node 10 of the upper module, wherein the cylindrical casing is welded and connected between the transverse partition 91 and the end steel plate 40, and the connecting bolt 60 The screw rod 62 passes through the entire casing 50 from bottom to top, and the nut 61 is exposed on the bottom of the end steel plate 40 on the H-shaped steel beam-column node 20 of the lower module, and the screw rod 62 of the connecting bolt 60 is connected from the upper module H-shaped steel The top surface of the transverse partition 91 of the beam-column node 10 protrudes, and the fastening nut 70 is screwed on the protruding end of the screw 62. It is carried out in the operating space of the structure, which effectively reduces the difficulty of operation.

[0073] It should be pointed out that when the connecting bolt 60 passes through the entire casing 50 fro...

Embodiment 2

[0075] see Figure 6-Figure 8 , the casing 50 in this embodiment includes a prismatic casing that is movably installed on the H-shaped steel beam-column node 10 of the upper module, and the prismatic casing passes through the transverse partition of the H-shaped steel beam-column node 10 of the upper module from top to bottom. The plate 91 and the transverse partition 91 are provided with a prismatic hole 51 matching the prismatic sleeve, and the nut 61 of the connecting bolt 60 is limited and accommodated at the bottom of the prismatic sleeve.

[0076] By setting the prismatic sleeve and accommodating the nut 61 of the connecting bolt 60 at the bottom of the prismatic sleeve, the fixing of the connecting bolt 60 can be reduced, and it is only necessary to connect the fastening nut 70 to the exposed bottom. The connecting bolts 60 of the end steel plates 40 of the module H-shaped steel beam-column nodes 20 can be connected to the upper and lower module nodes, which effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com