Tubular pile static bearing capacity testing method and system based on traveling wave tracing principle

A test method and technology of bearing capacity, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of empirical judgment of parameters, many parameters, and large deviation of test results, etc., to achieve real-time monitoring and overcome consumption Time-consuming, wide-ranging applicability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The core idea of the method of the present invention is to use the traveling wave propagating along the pile body to reflect the soil resistance characteristics of the pile side and pile tip, and then determine the ultimate bearing capacity of the whole pile. The specific implementation steps of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0056] The method for testing the static bearing capacity of pipe piles based on the principle of traveling wave tracing in the embodiment of the present invention comprises the following steps:

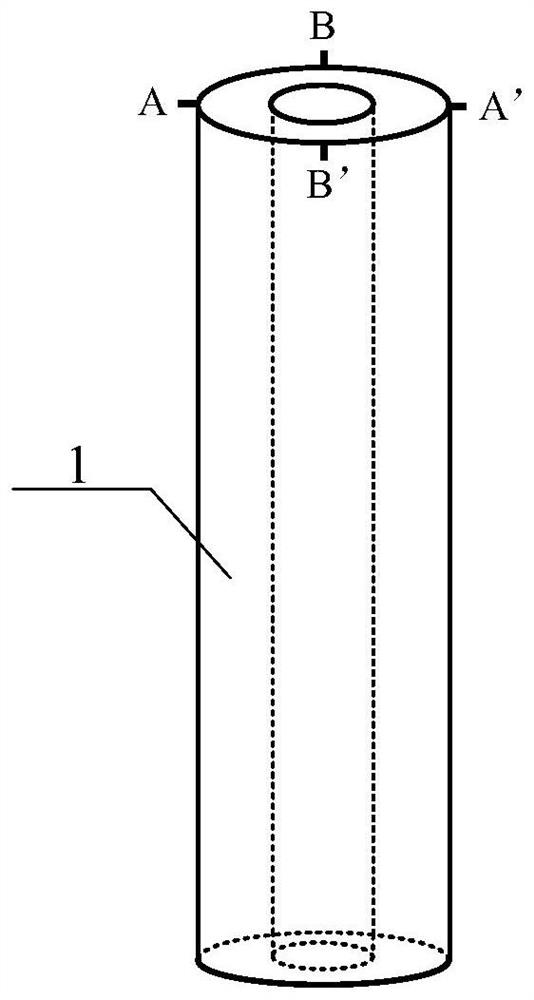

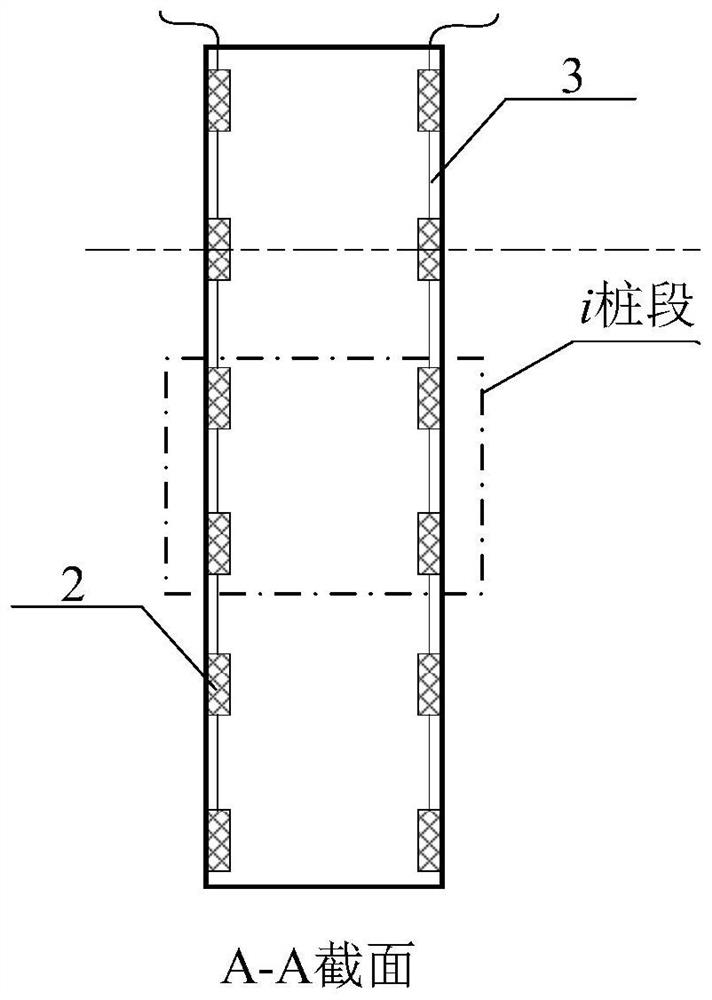

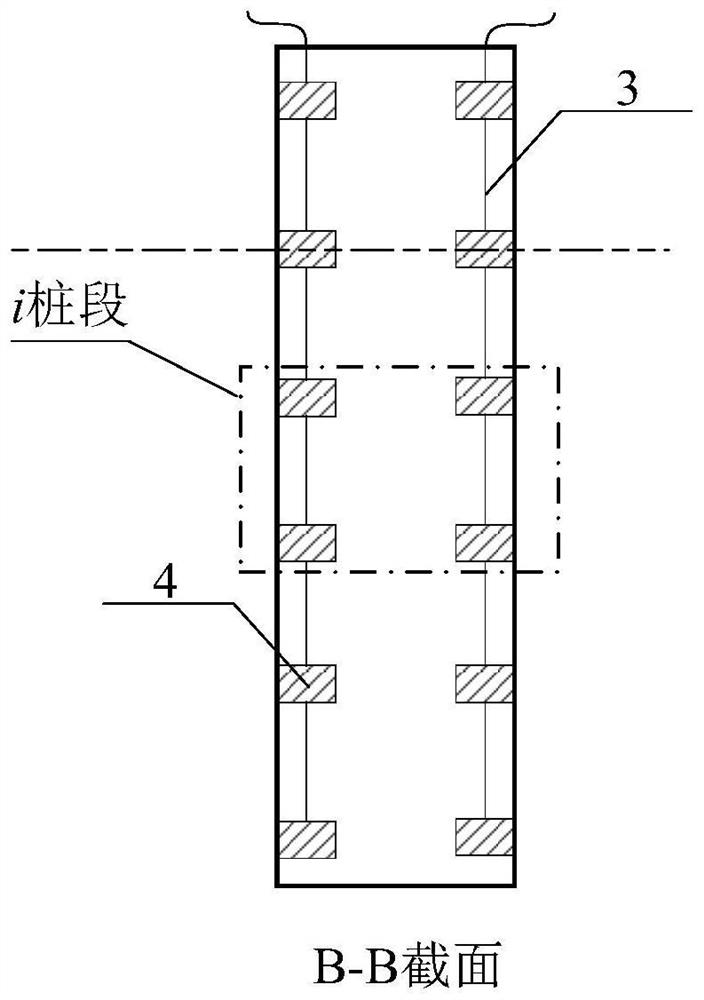

[0057] 1. Install the sensor. Before piling construction, strain sensors and acceleration sensors are arranged in a specific arrangement on the inner wall of the pipe pile 1 along the axial direction of the pile body, such as figure 1 As shown, several strain sensors 2 distributed along the axial direction form a distributed strain gauge, and several acceleration sensors 4 distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com