Slow-release polycarboxylate superplasticizer as well as preparation method and application thereof

A slow-release polycarboxylic acid and water-reducing agent technology, applied in the field of building material admixtures, can solve the problems of excessive concrete slump loss, concrete segregation, delayed bleeding, etc., so as to achieve no pollution in the synthesis process and reduce economic cost, the effect of improving the placement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

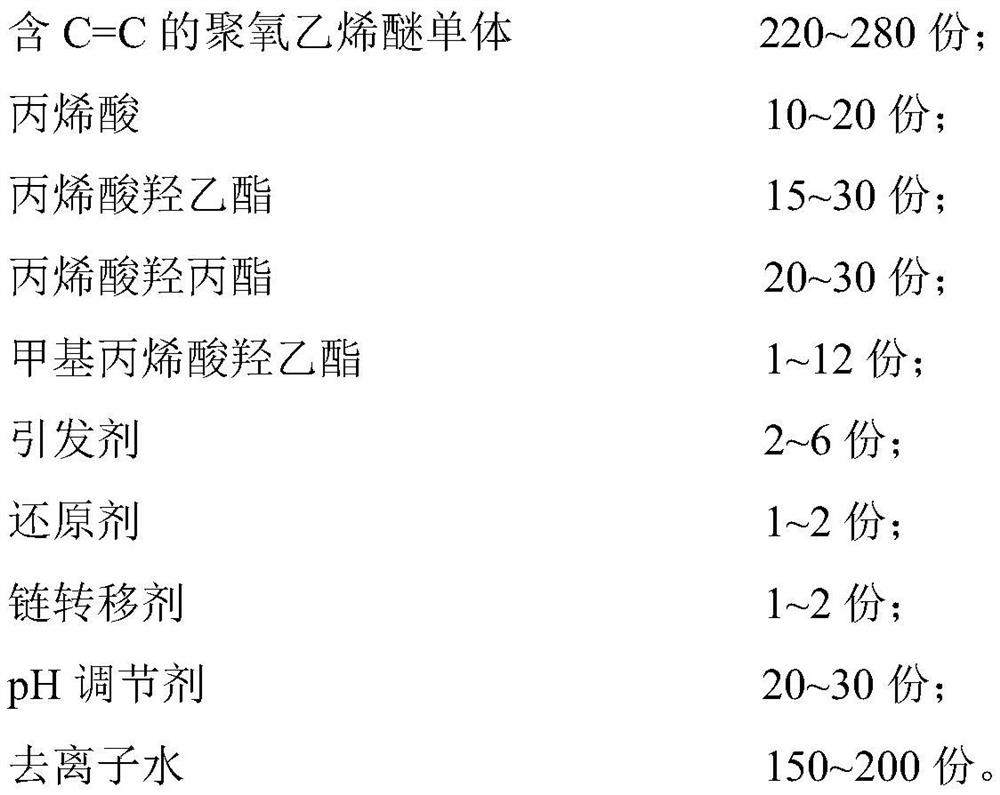

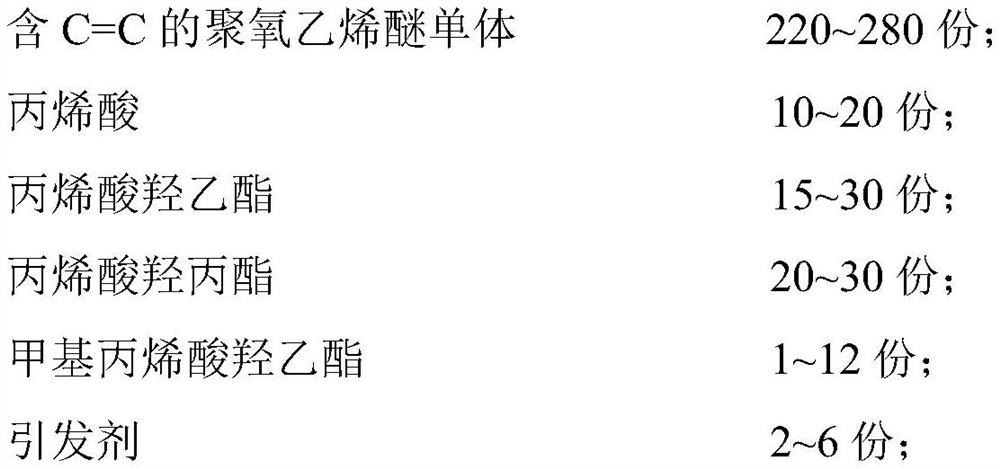

[0046] This embodiment provides a slow-release polycarboxylate water reducer and its preparation method, the specific details are as follows:

[0047] S1: Add 240g of Auke 801 polyoxyethylene ether macromonomer, 196g of deionized water, and 3.78g of hydrogen peroxide according to the weight percentage into a four-necked flask connected with a stirring device and a thermometer with a capacity of 1L, and configure it as a bottom liquid;

[0048] S2: Add 10.8g of acrylic acid, 23.2g of hydroxyethyl acrylate, 26.03g of hydroxypropyl acrylate, 6.51g of hydroxyethyl methacrylate into Erlenmeyer flask A, and add 20g of deionized water to obtain liquid A;

[0049] S3: Add 1 g of ascorbic acid, 1 g of mercaptopropionic acid, and 30 g of deionized water into Erlenmeyer flask B.

[0050] S4: Use a peristaltic pump to continuously drop liquid A and liquid B into the bottom liquid of the four-necked flask, and control the dripping time for 180 minutes under constant stirring at a temperatu...

Embodiment 2

[0053] This example provides a slow-release polycarboxylate superplasticizer, the preparation method and proportion of which are the same as those in Example 1. The difference from Example 1 is that 10.8g of acrylic acid, 29.0g of hydroxyethyl acrylate, 29.0g of hydroxyethyl acrylate, 19.5 g of hydroxypropyl acrylate and 6.51 g of hydroxyethyl methacrylate were used to obtain a slow-release polycarboxylate superplasticizer.

Embodiment 3

[0055] This example provides a slow-release polycarboxylate superplasticizer, the preparation method and proportion of which are the same as those in Example 1. The difference from Example 1 is that 10.8 g of acrylic acid and 29.0 g of hydroxyethyl acrylate are added to liquid A. , 13.0 g of hydroxypropyl acrylate, and 13.0 g of hydroxyethyl methacrylate to obtain a slow-release polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com