Oxygen generator, gas storage tank of oxygen generator and forming die and forming method of gas storage tank

A technology for forming molds and gas storage tanks, which is applied to chemical instruments and methods, fixed-capacity gas storage tanks, and other household appliances. The effect of improving heat dissipation efficiency and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

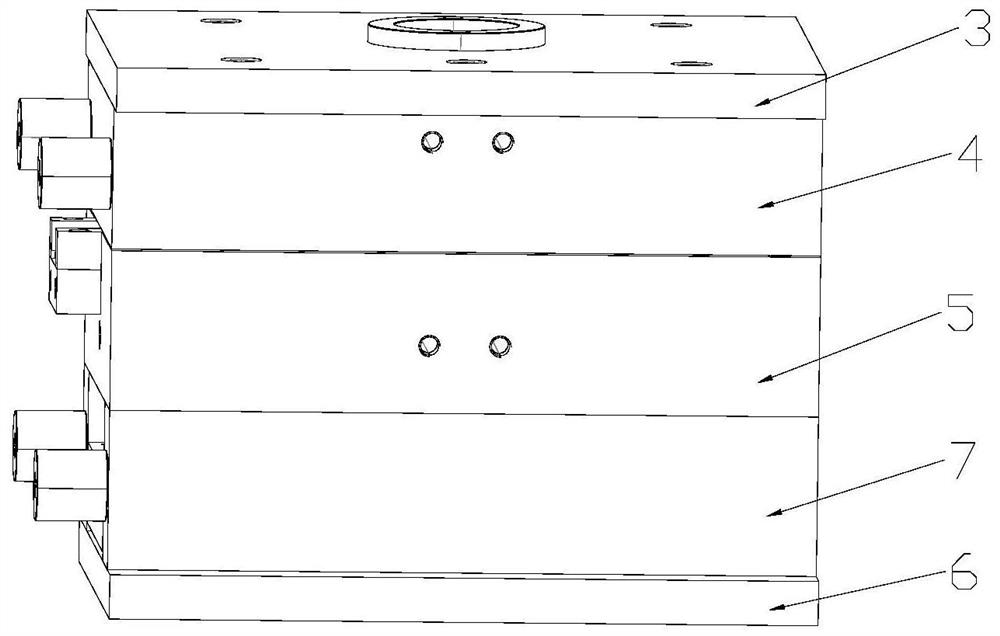

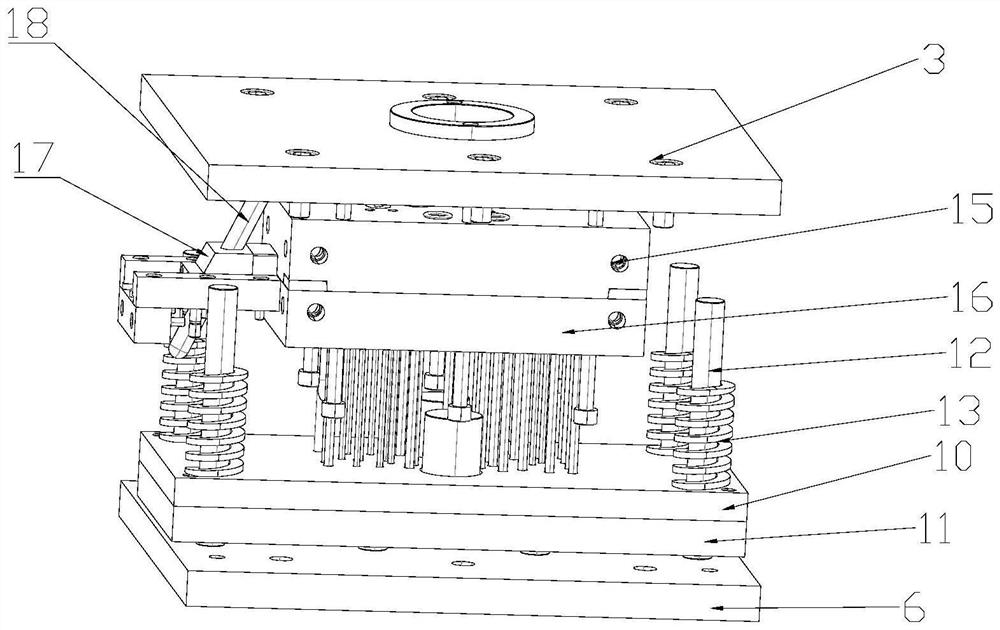

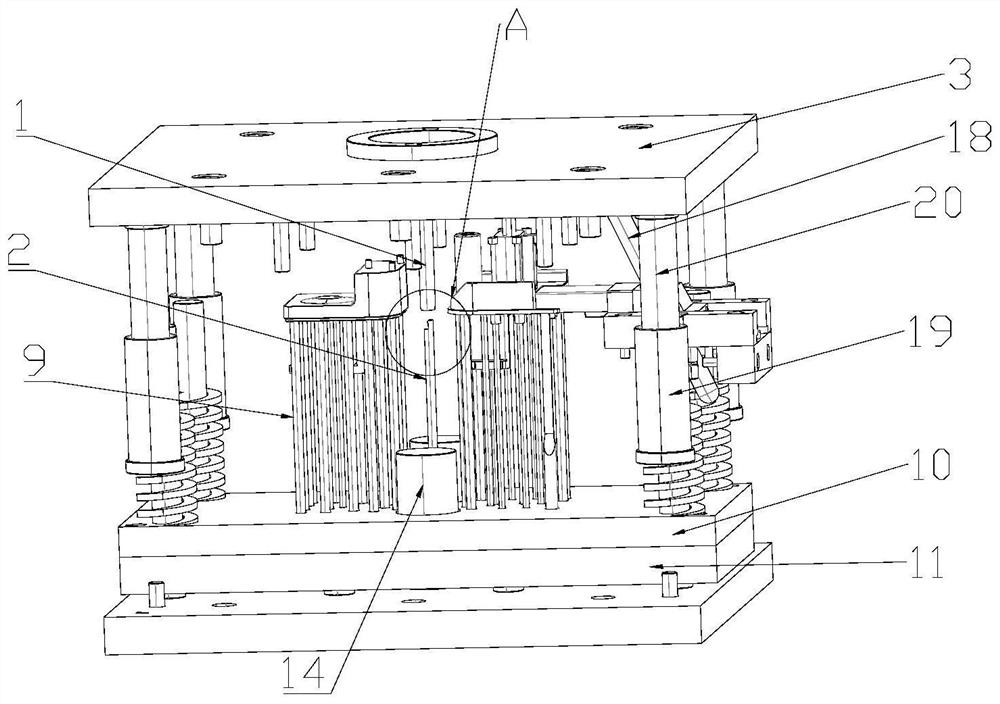

[0065] Such as Figures 1 to 5 Shown, a kind of air storage tank forming mold comprises at least two cavities, and the cavity is arranged in the middle of the forming mold; the injection channel 1, the injection channel 1 is arranged in the upper part of the forming mold, and its upper port extends to the forming mold The upper end surface of the upper end, the lower end of which is connected to the cavity; the pulling rod 2, the upper end of the pulling rod 2 blocks the lower port of the injection channel 1; the first jacking part, the lower part of the cavity is provided with The corresponding first jacking member. The injection slurry is injected into the cavity from the injection channel 1 to form the finished gas storage tank. The finished product is released from the cavity through the first jacking part, and the slurry forms condensate in the injection channel 1, which affects the next grouting. After the condensate condenses, it is connected to the upper end of the pu...

Embodiment 2

[0076] Such as Figures 6 to 7 As shown, the gas storage tank of the oxygen generator includes an upper cover 21, which is molded through a cavity in the above-mentioned forming mold; a tank body 22, which is formed by another type of the above-mentioned forming mold. The cavity is formed; the upper cover 21 is ultrasonically welded on the upper end surface of the tank body 22 to form a sealed first cavity. The first air inlet 25 is arranged on one side of the upper cover 21, which communicates with the first cavity; the first air outlet 26 and the first air inlet 25 are arranged on the same side of the upper cover 21, which communicated with the first cavity. On the upper cover 21 of the second cavity 24; the second air inlet 27 is arranged between the first air inlet 25 and the first air outlet 26, and it communicates with the second cavity 24; the second air outlet 28 is arranged between the first air inlet 27 and the first air outlet 26, which communicates with the secon...

Embodiment 3

[0082] A method for forming an oxygen generator gas storage tank, comprising the following steps:

[0083] S1. Clamp the upper template 3, the upper mold base 4, the lower template 5 and the lower mold base 6;

[0084] S2. Pass coolant into the cooling channel;

[0085] S3. inject the slurry into the cavity through the injection channel 1, and form the gas storage tank product;

[0086] S4. Ejecting the product through the first jacking member and the first jacking member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com