Crab-shaped automatic climbing jig and method for bars and feeding equipment

A bar, automatic technology, applied in the field of machinery, can solve the problems of inability to adapt to the processing of bars, occupying labor production resources, prolonging production time, etc., to reduce manpower and processing time, improve flexibility and adaptability, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

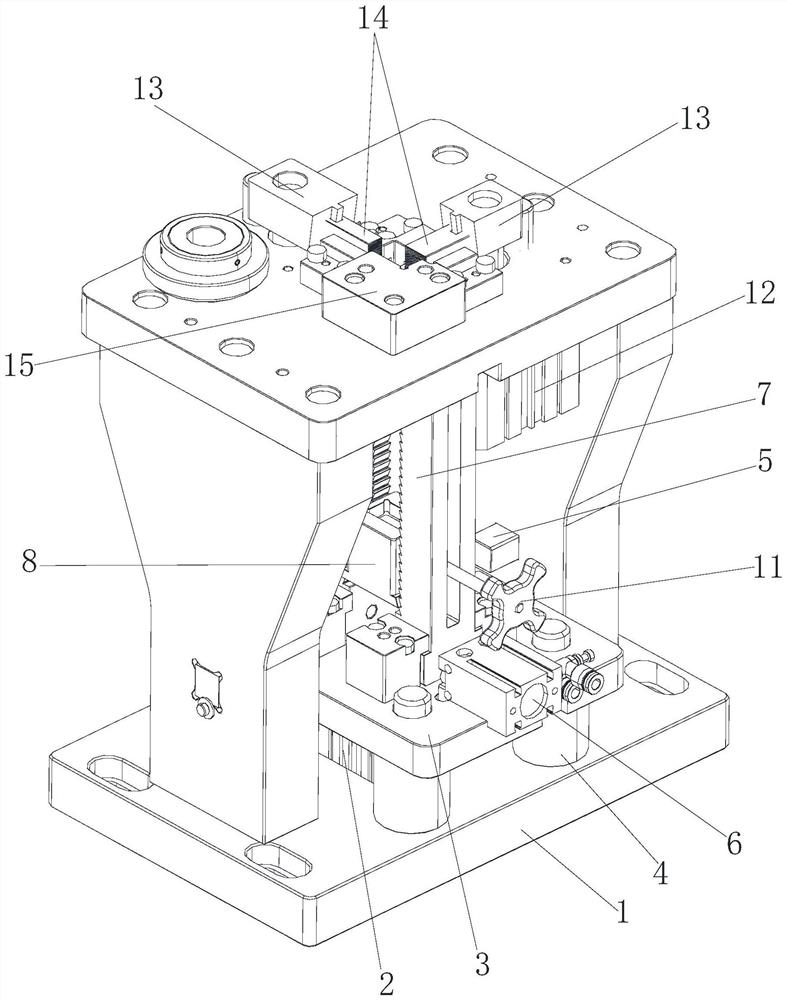

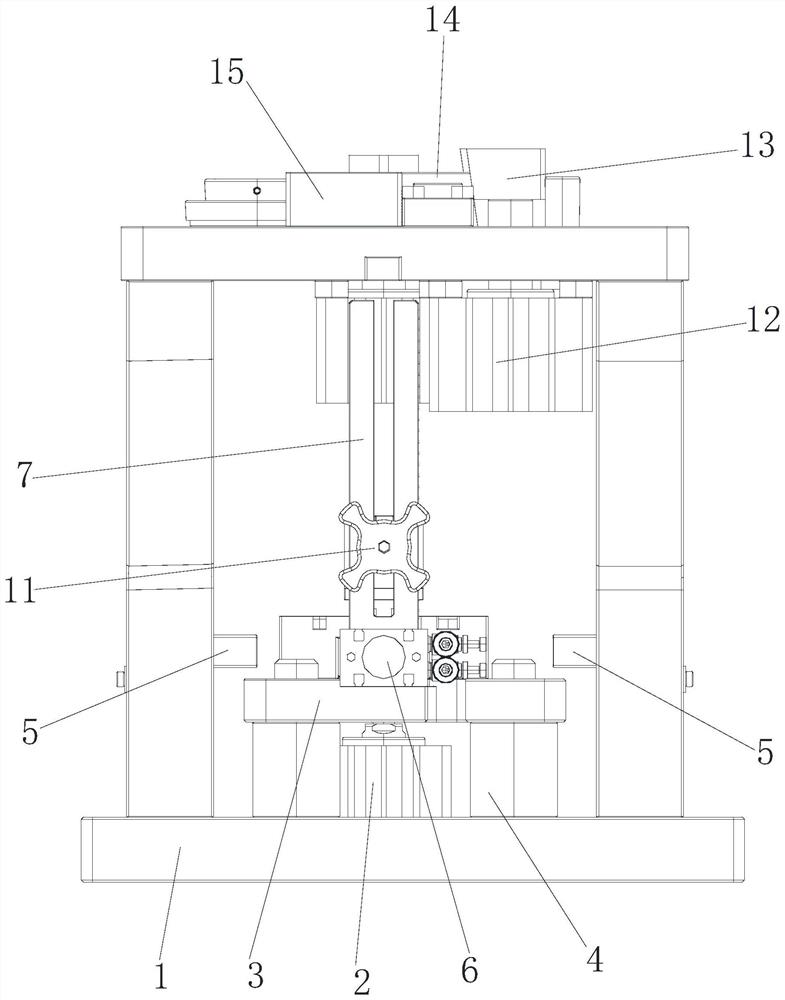

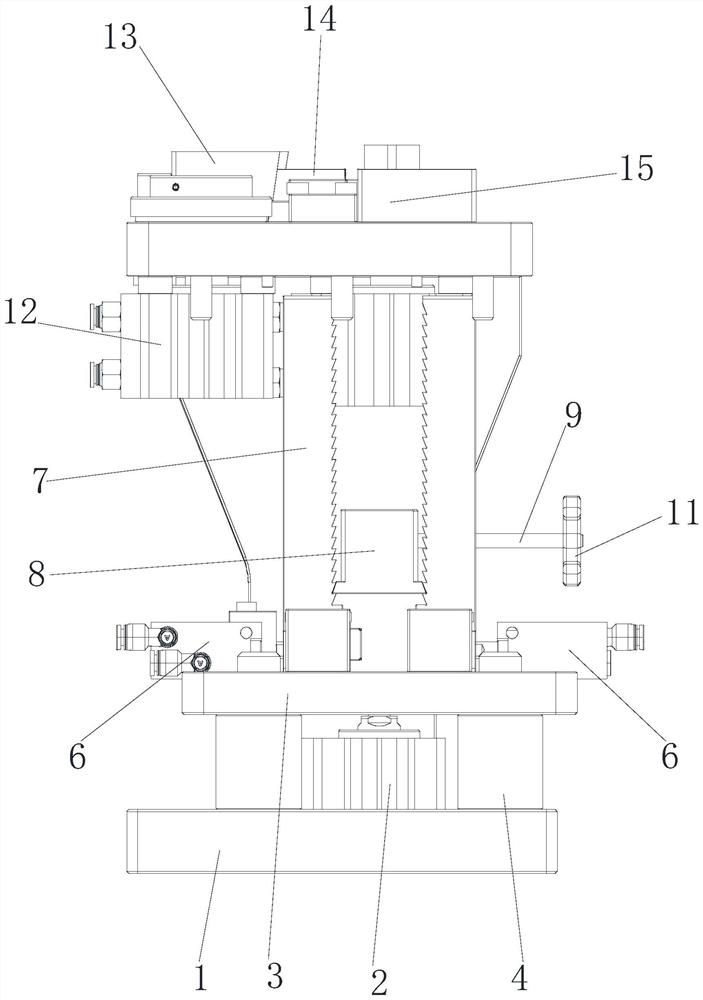

[0036] like Figures 1 to 4 As shown, the crab-shaped automatic climbing fixture for rods includes a frame 1 with a clamping platform, a feeding channel is opened on the clamping platform, and a bottom lifting mechanism, a middle climbing mechanism and a top clamping mechanism are also included;

[0037] The middle layer climbing mechanism includes a floating seat 8 located directly below the feeding channel. The climbing rack 7 is sandwiched symmetrically on both sides of the floating seat 8. The two sides of the floating seat 8 are protrudingly provided with conical teeth. The side walls of the climbing rack 7 Sawtooth slots are arranged on the top, and the conical teeth mesh with the sawtooth slots to form a directional limit snap connection, and the climbing rack 7 is connected by translational drive of the climbing power unit 6 .

[0038] In the crab-shaped automatic climbing fixture for rods, the frame 1 includes a bottom plate on which two support plates are erected sym...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, the difference is:

[0060] The clamping assembly includes a clamping push-pull mounted on the top surface of the clamping platform, and the push-pull shaft of the clamping push-pull is fixedly connected with the pressing block 14 . The clamping push-pull specifically adopts a cylinder, a hydraulic cylinder or an electric push rod; the cylinder is specifically a multi-solid straight extension cylinder.

Embodiment 3

[0062] Based on Embodiment 1 and Embodiment 2, the difference of this embodiment is:

[0063] A crab-shaped automatic climbing and feeding device for bars, comprising the above-mentioned crab-shaped automatic climbing jig for bars.

[0064] Compared with the prior art, the crab-shaped automatic climbing and feeding equipment for bars has the following beneficial effects:

[0065] The present invention cooperates with the operation of the driving components, and cooperates with the sawtooth clamping groove like a crab claw to effectively change the bearing position of the Z-direction reference. Thereby expanding the range of use of the jig, improving flexibility and adaptability, while reducing cutting steps, reducing manpower and processing time, reducing processing costs, improving work efficiency, and increasing economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com