Quick charge type lithium ion battery module structure

A lithium-ion battery and module structure technology, which is applied to battery pack parts, structural parts, secondary batteries, etc., can solve the problems of insufficient module strength, affecting battery life, capacity, and loss of battery performance, etc., to achieve increased The liquid cooling area, the effect of improving the natural heat transfer coefficient and improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

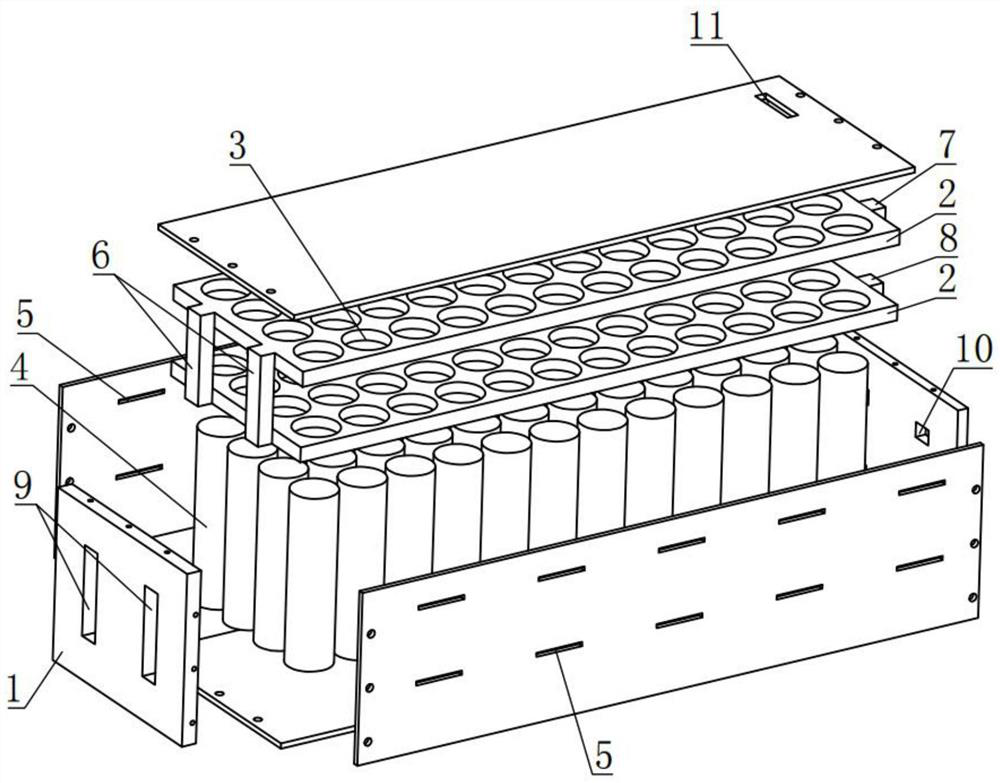

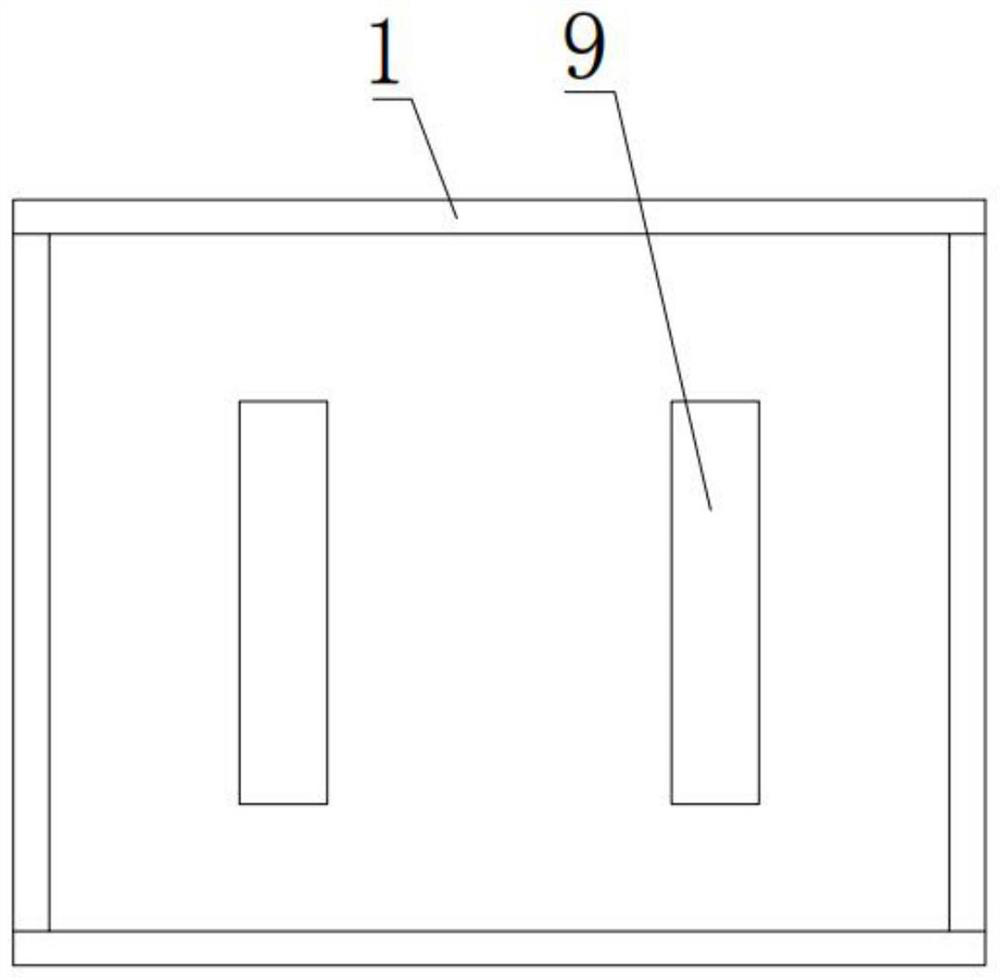

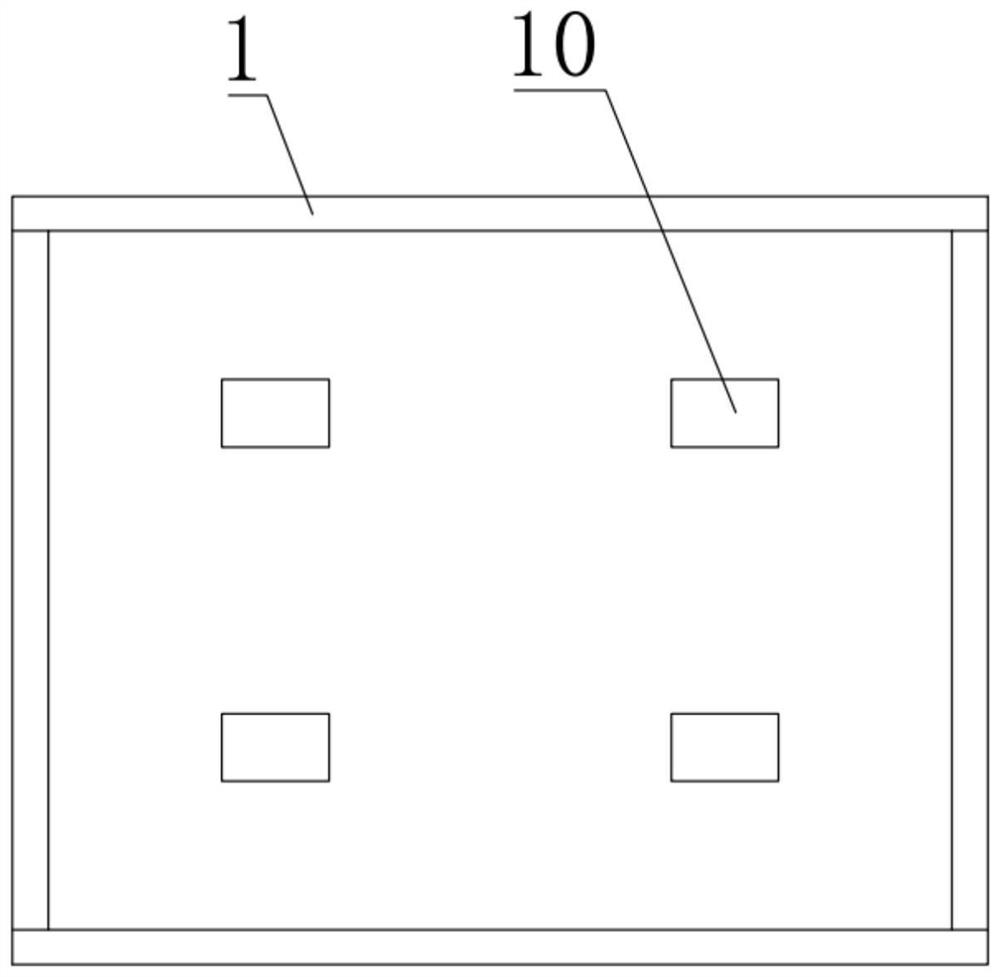

[0022] refer to figure 1 As shown, the present invention discloses a fast-charging lithium-ion battery module structure, including: a battery box 1 and a cooling plate 2; the cooling plate 2 is arranged inside the battery box 1; The cooling liquid channel, and it is provided with a plurality of battery jacks 3 that run through the upper and lower surfaces of the cooling plate 2; each battery jack 3 is inserted with a lithium-ion battery 4; the wall of the battery box 1 is provided with The air vent 5 communicating with the inside of the battery box 1 .

[0023] In this embodiment, the cooling plate 2 is a hollow structure, and a closed cooling liquid channel is formed between the hole wall of the battery socket 3 and the outer wall of the cooling plate 2, so that the large lithium-ion battery 4 can be in close contact with the cooling liquid channel;

[0024] In this embodiment, the number of cooling plates 2 is 2; the two cooling plates 2 are divided into upper and lower lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com