Heating and ventilation pipeline classification design method based on BIM

A design method and pipeline technology, applied in cleaning methods and utensils, chemical instruments and methods, instruments, etc., can solve the problems of troublesome dismantling and cleaning of staff, small hole diameter of heating pipes, affecting heating ventilation, etc., to ensure heating and ventilation Efficiency, ensuring cleanliness, improving heating ventilation and ventilation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

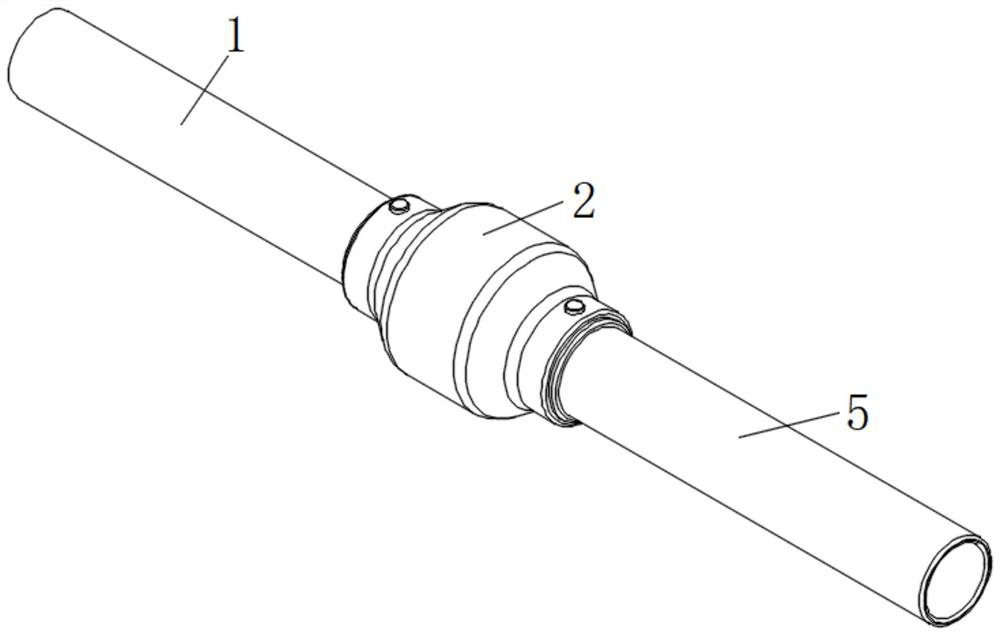

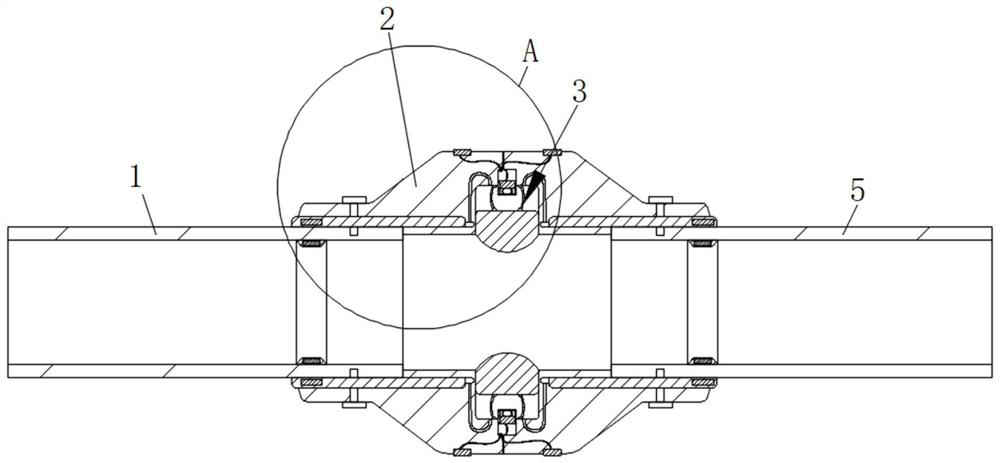

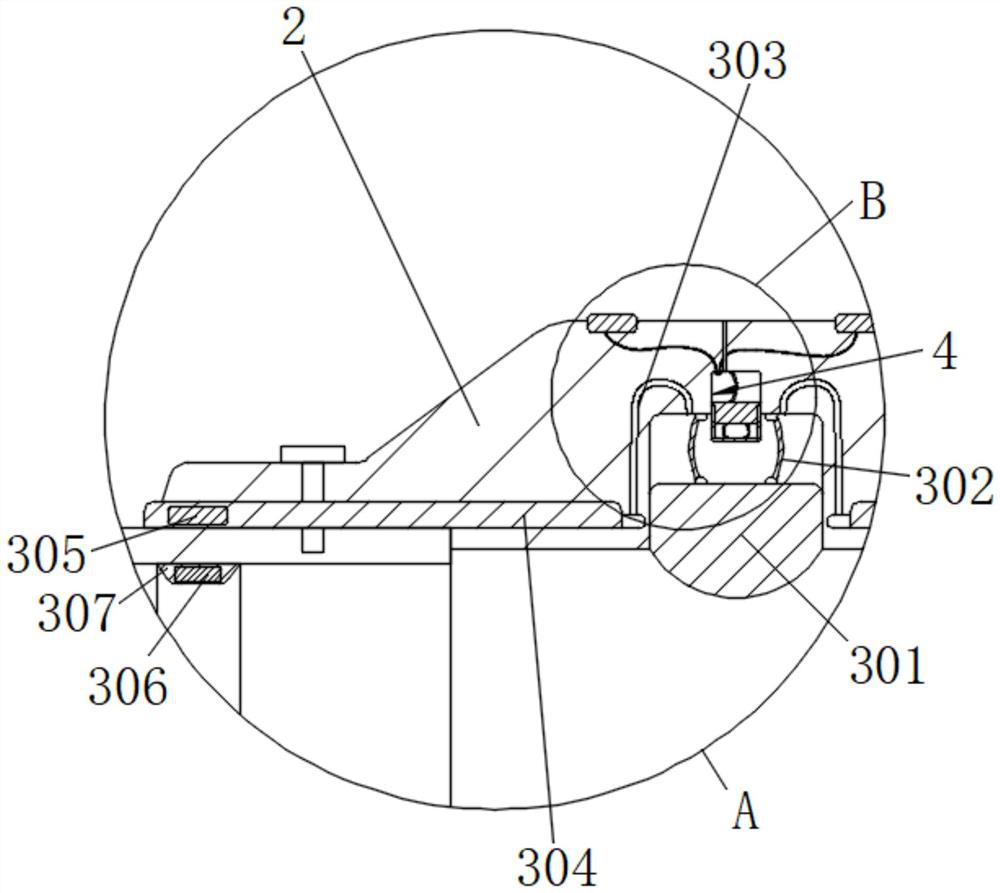

[0024] see Figure 1-4 , the present invention provides a technical solution: a BIM-based HVAC pipeline classification design method, including connecting pipes 2, drawing the different layout orientations of the HVAC pipelines in Revit software, and then carrying out pipelines according to their names and materials The system distinguishes and classifies, and finally sets the color correspondingly according to different materials, and finally connects each pipe and the connecting pipe 2 with bolts;

[0025] There is a fine air groove inside the connecting pipe 2, and the inside of the fine air groove communicates with the inside of the small chute. The inner wall of the connecting pipe 2 is slidably connected to the HVAC pipe A1, and the inner wall of the connecting pipe 2 is slidably connected to the HVAC pipe B5. The inner wall of the connecting pipe 2 is connected to the The outer walls of HVAC pipeline A1 and HVAC pipeline B5 are fixed and installed by bolts, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com