Multifunctional graded stirring device for constructional engineering

A technology for construction engineering and mixing devices, which is applied in cement mixing devices, clay preparation devices, and raw material supply devices for sale, etc., can solve problems such as inability to combine with cleaning, single mixing function, and high cost, and achieve efficient screening effects. The effect of thorough, good stirring effect and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

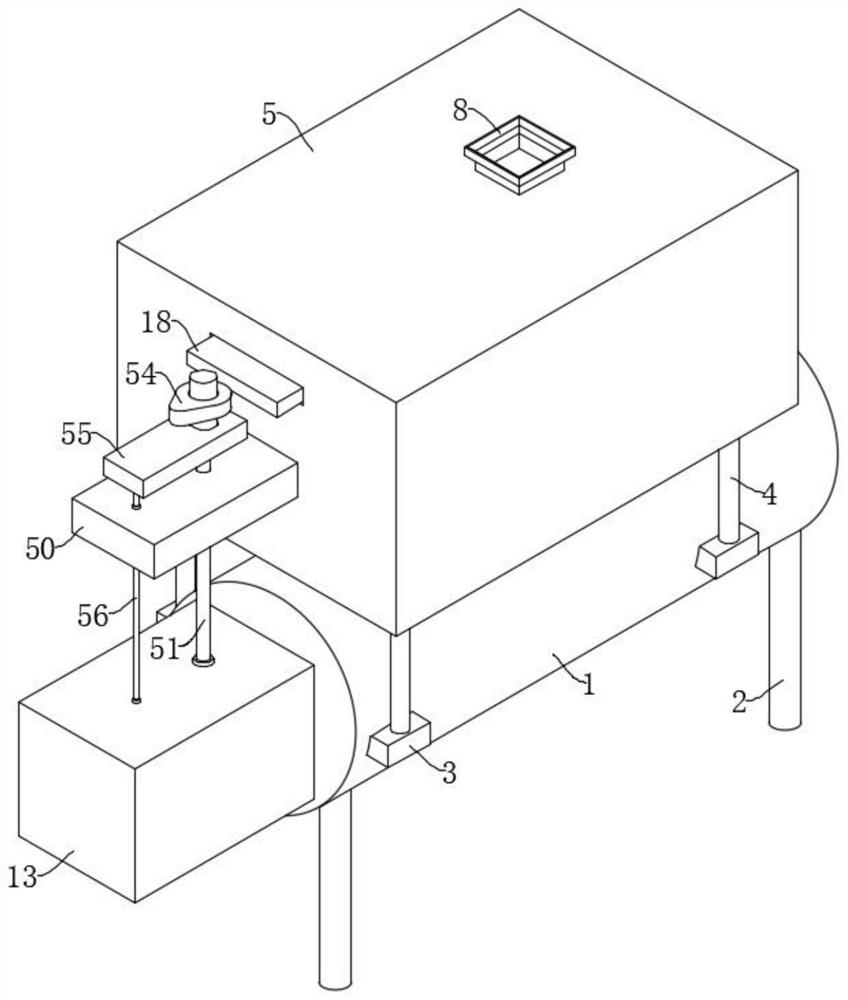

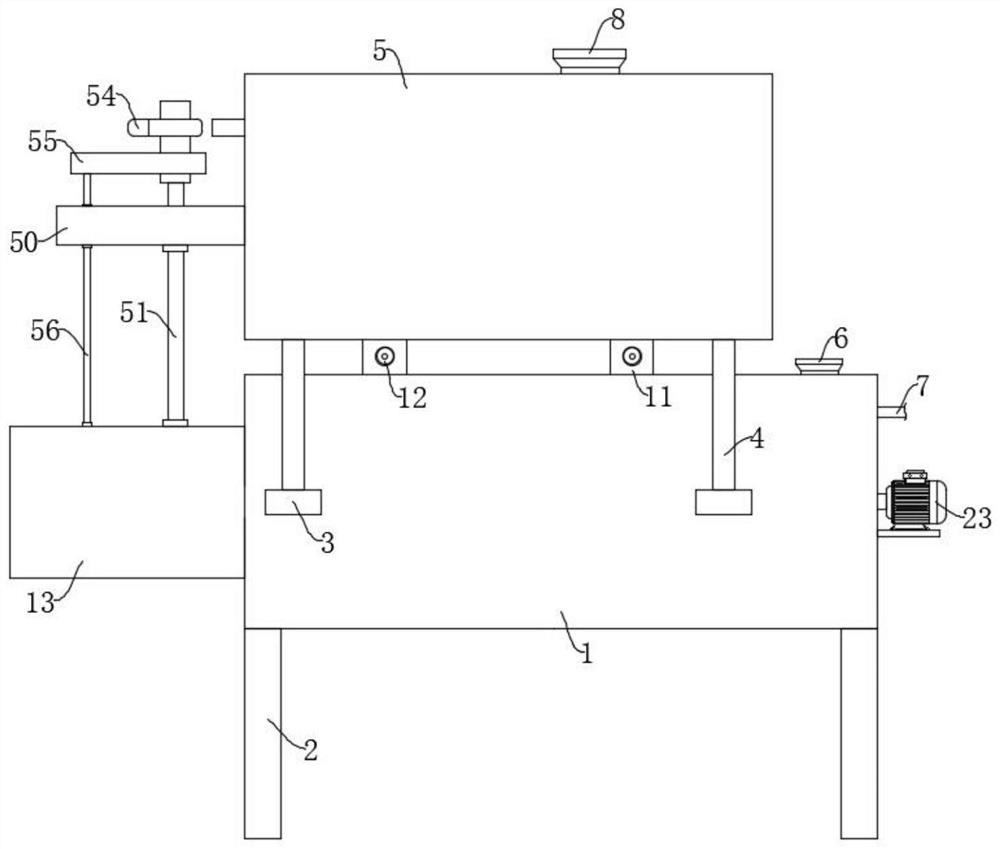

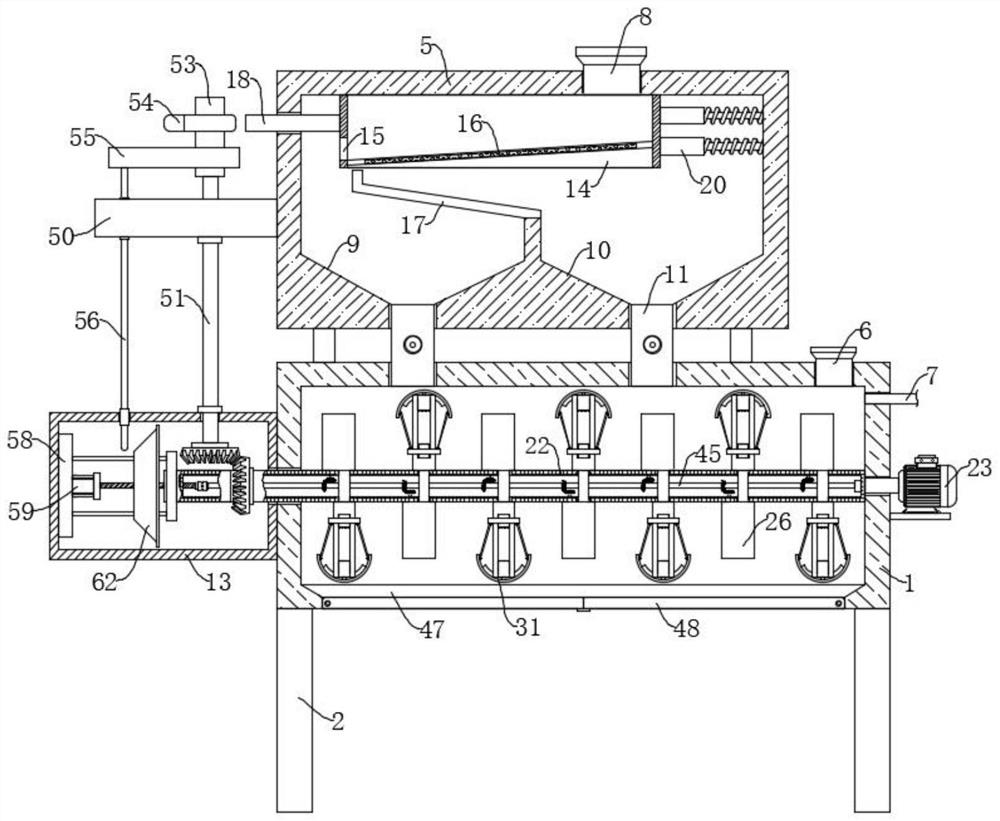

[0051] like Figure 1-13 As shown in the figure, a multi-functional grading stirring device for construction engineering includes a mixing drum 1. The four corners of the bottom outer wall of the mixing drum 1 are fixedly connected with support legs 2, and the outer wall of the mixing drum 1 is symmetrically and fixedly connected with four fixed blocks 3. The tops of the four fixing blocks 3 are fixedly connected with vertical rods 4, and the tops of the four vertical rods 4 are fixedly connected with the same sorting box 5 located above the mixing drum 1, and the top of the sorting box 5 is provided with a feeding hopper 8, The bottom inner wall of the sorting box 5 is respectively provided with a coarse material collection tank 9 and a fine material collection tank 10, and the top of the mixing drum 1 is fixedly connected with two discharge materials which are respectively communicated with the coarse material collection tank 9 and the fine material collection tank 10. Pipe ...

Embodiment 2

[0059] This embodiment is a further improvement of the previous embodiment: as Figure 1-13 As shown in the figure, a multi-functional grading stirring device for construction engineering includes a mixing drum 1. The four corners of the bottom outer wall of the mixing drum 1 are fixedly connected with support legs 2, and the outer wall of the mixing drum 1 is symmetrically and fixedly connected with four fixed blocks 3. The tops of the four fixing blocks 3 are fixedly connected with vertical rods 4, and the tops of the four vertical rods 4 are fixedly connected with the same sorting box 5 located above the mixing drum 1, and the top of the sorting box 5 is provided with a feeding hopper 8, The bottom inner wall of the sorting box 5 is respectively provided with a coarse material collection tank 9 and a fine material collection tank 10, and the top of the mixing drum 1 is fixedly connected with two discharge materials which are respectively communicated with the coarse material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com