Temporary supporting structure of steel structure building and construction method

A temporary support and steel structure technology, applied in building components, special structures, building structures, etc., can solve the problems of structural instability, long construction period, affecting building stability, etc., and achieve simple structure erection and short construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

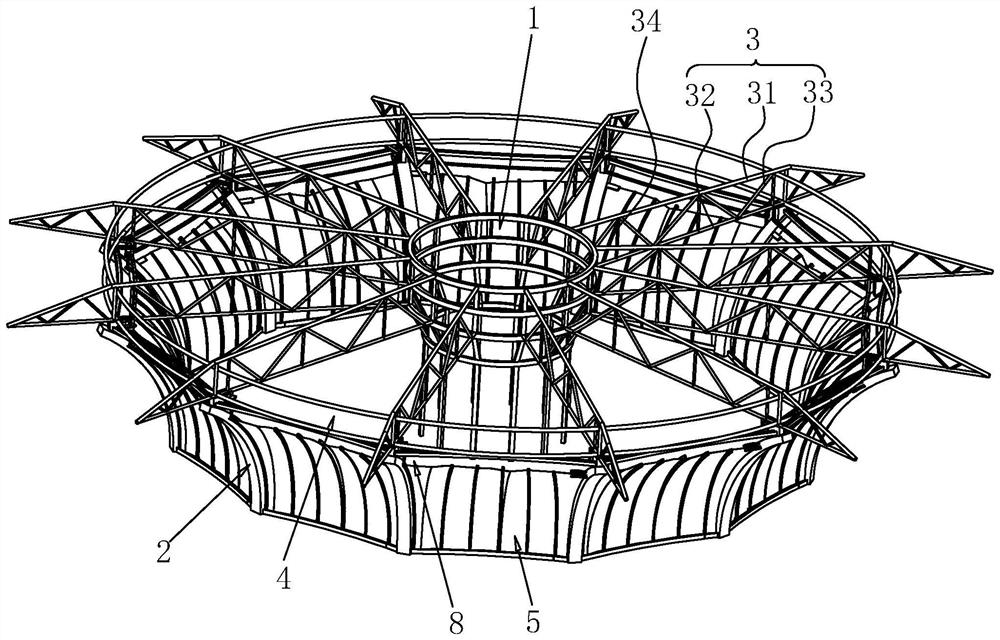

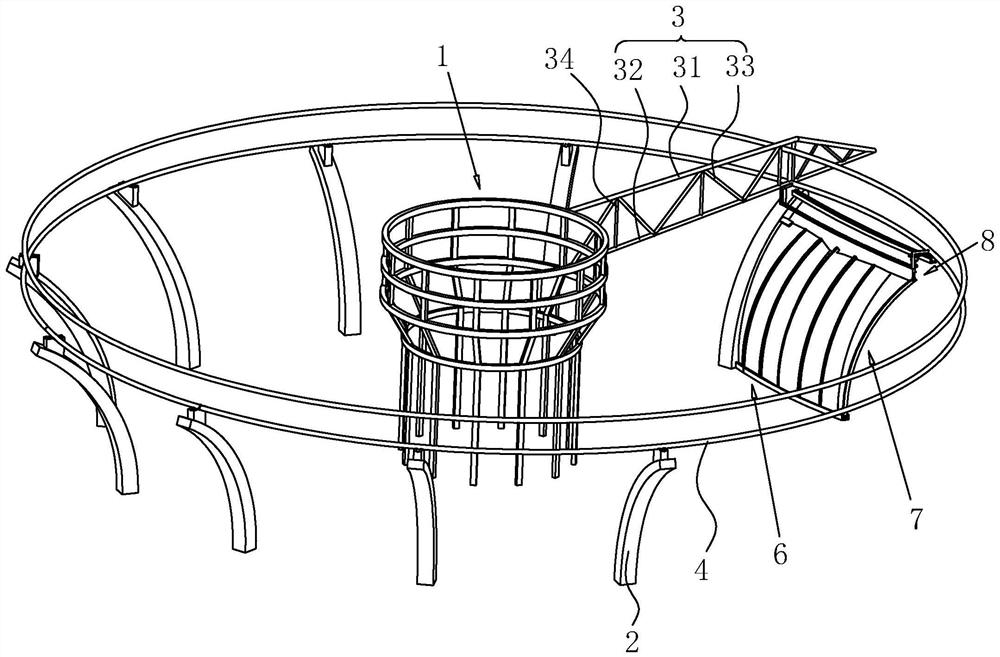

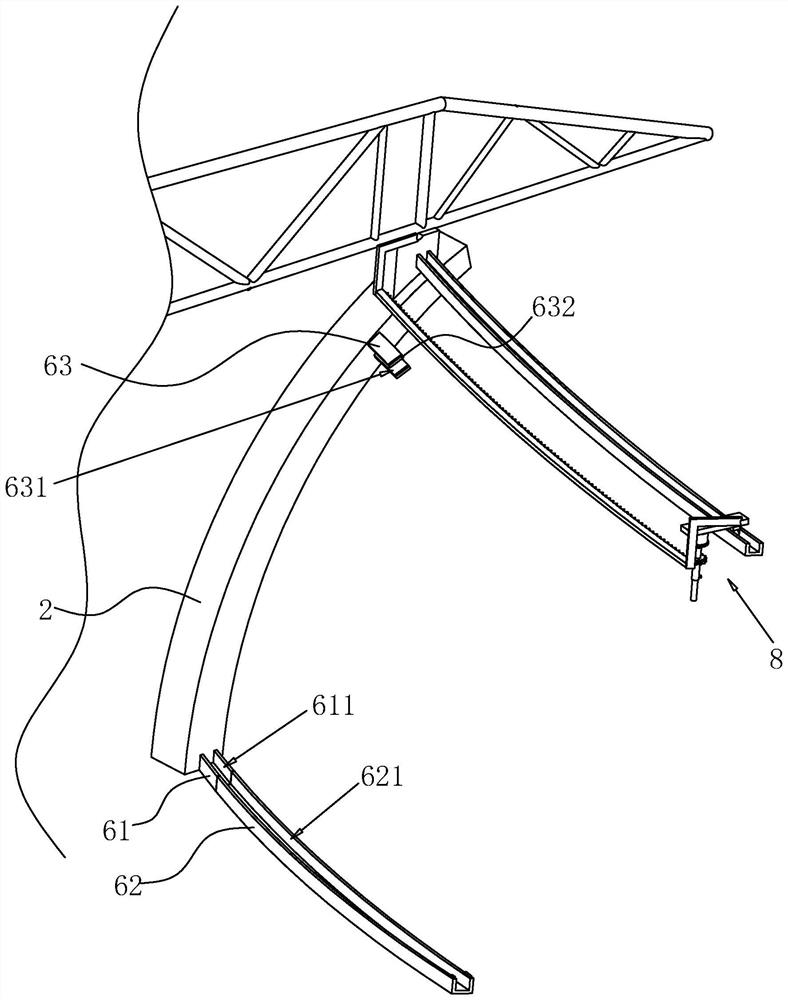

[0045] The following is attached Figure 1-6 The application is described in further detail.

[0046] The embodiment of this application discloses a temporary support structure for a steel structure building. figure 1 , 2 , including a central vertical column 1, a peripheral arc-shaped column 2, a radial truss 3 and a peripheral circumferential truss 4; the central vertical column 1 is installed on the ground, and the peripheral arc-shaped column 2 is provided with a In this embodiment, there are 12 peripheral arc-shaped columns 2, radial truss beams 3 and peripheral circumferential trusses 4; are also equal; the radial truss 3 is erected between the top of the central vertical column 1 and the peripheral arc-shaped column 2, and one peripheral arc-shaped column 2 corresponds to one radial truss 3; two adjacent peripheral arc-shaped Peripheral hoop trusses 4 are erected between the columns 2, and both ends of the peripheral hoop trusses 4 are respectively connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com