Operation method for stabilizing carbon content of duplex molten iron of converter

An operation method and a technology of carbon content, applied in steel manufacturing process, converter manufacturing, metal processing, etc., can solve problems affecting production smoothness, converter operation instability, etc., to improve production efficiency, stable control, and stability The effect of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

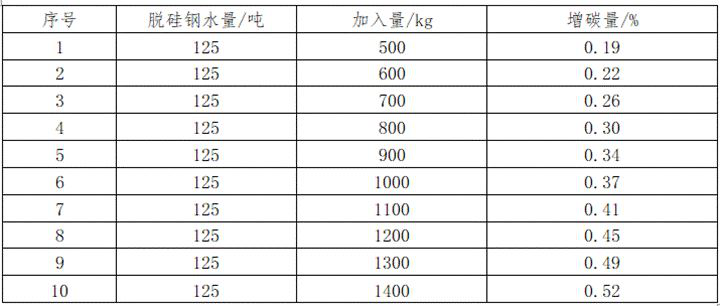

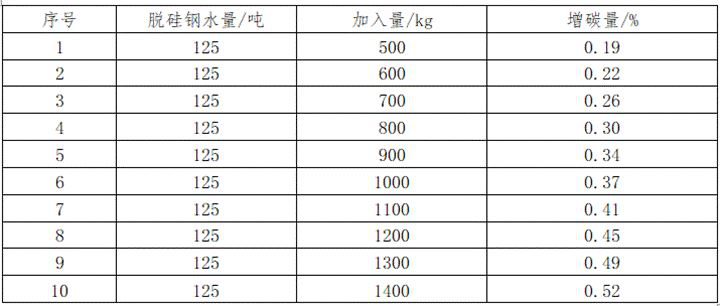

[0010] An operation method for the carbon content of molten iron after the converter is stabilized and double-connected. According to the tracking data, coke is added during the tapping process: the carbon content is 80%-85%, and the recovery rate of burning phenomenon is between 45%-55%. The compensation is calculated to The addition amount of the target carbon content is shown in the table below:

[0011]

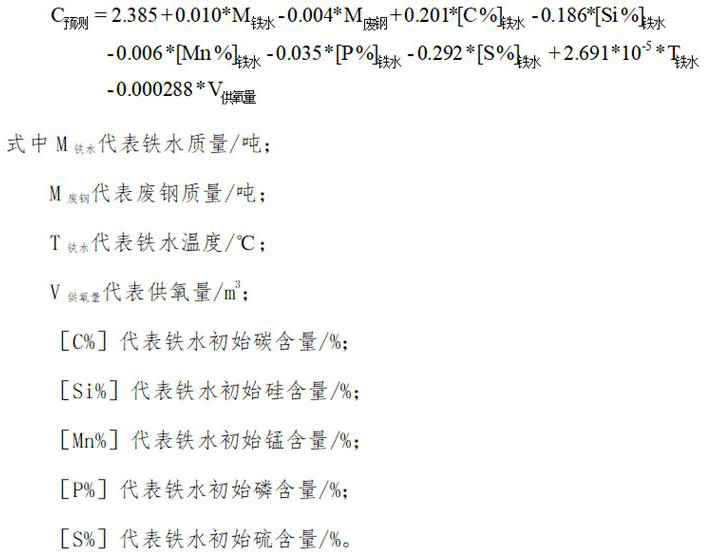

[0012] According to the deviation between the predicted value and the target value, coke is selected to be added during the tapping process, the carbon content of molten steel after desiliconization is controlled between 2.5% and 3.0%, and the smelting time of molten steel after stable desiliconization is 8-10 minutes, which is the smelting process Provide sufficient reaction time for temperature raising and dephosphorization, and stabilize the subsequent smelting operation of double-linked molten iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com