Device and method for removing organic sulfur and inorganic sulfur in coal gas by wet process

An organic sulfur and inorganic sulfur technology, applied in gas dust removal, combustible gas purification, removal of gas pollutants, etc., can solve the problems of high desulfurization cost, difficult waste liquid treatment, large gas pressure loss, etc., and achieve the technical process route. The effect of short, low desulfurization cost and small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Blast furnace gas after TRT in a steel company, temperature 40-60℃, pressure 6-10kPa, total sulfur content 80-130mg / Nm 3 , of which the hydrogen sulfide content is 30-50mg / Nm 3 , the sulfur dioxide content is less than 10mg / Nm 3 , carbonyl sulfide content 50-70mg / Nm 3 , carbon disulfide content is less than 5mg / Nm 3 , using the device and method of the present invention to carry out the side line desulfurization test, the sulfur-containing gas flow rate is 3000Nm 3 / h, supergravity rotating bed desulfurizer circulating flow rate 1m 3 / h, the flow rate of rich desulfurizer sent to the sedimentation tank is 0.1m 3 / h, the total sulfur in the gas after desulfurization does not exceed 20mg / Nm 3 , wherein the hydrogen sulfide content does not exceed 5 mg / Nm 3 .

Embodiment 2

[0031] Blast furnace gas after TRT in a steel company, temperature 50-70℃, pressure 8-12kPa, total sulfur content 150-240mg / Nm 3 , of which hydrogen sulfide content is 50-90mg / Nm 3 , the sulfur dioxide content is less than 10mg / Nm 3 , carbonyl sulfide content 80-110mg / Nm 3 , carbon disulfide content 10-30mg / Nm 3 , hydrogen chloride content 10-30mg / Nm 3 , using the device and method of the present invention to carry out the side line desulfurization test, the test gas flow rate is 4000Nm 3 / h, supergravity rotating bed desulfurizer circulation flow 2m 3 / h, the flow rate of rich desulfurizer sent to the sedimentation tank is 0.2m 3 / h, the total sulfur in the gas after desulfurization does not exceed 20mg / Nm 3 , wherein the hydrogen sulfide content does not exceed 5 mg / Nm 3 .

Embodiment 3

[0033] A company's coke oven gas, the total sulfur content of the gas is 450-600mg / Nm 3 , of which the hydrogen sulfide content is 150-200mg / Nm 3 , carbonyl sulfide and carbon disulfide content 300-400mg / Nm 3 , using the device and method of the present invention to carry out the side line desulfurization test, the sulfur-containing gas flow rate is 3000Nm 3 / h, temperature 30-45°C, pressure 10-15kPa, supergravity rotating bed desulfurizer circulation flow 3m 3 / h, the flow rate of rich desulfurizer sent to the sedimentation tank is 0.45m 3 / h, the total sulfur in the gas after desulfurization does not exceed 20mg / Nm 3 , wherein the hydrogen sulfide content does not exceed 5mg / Nm 3 .

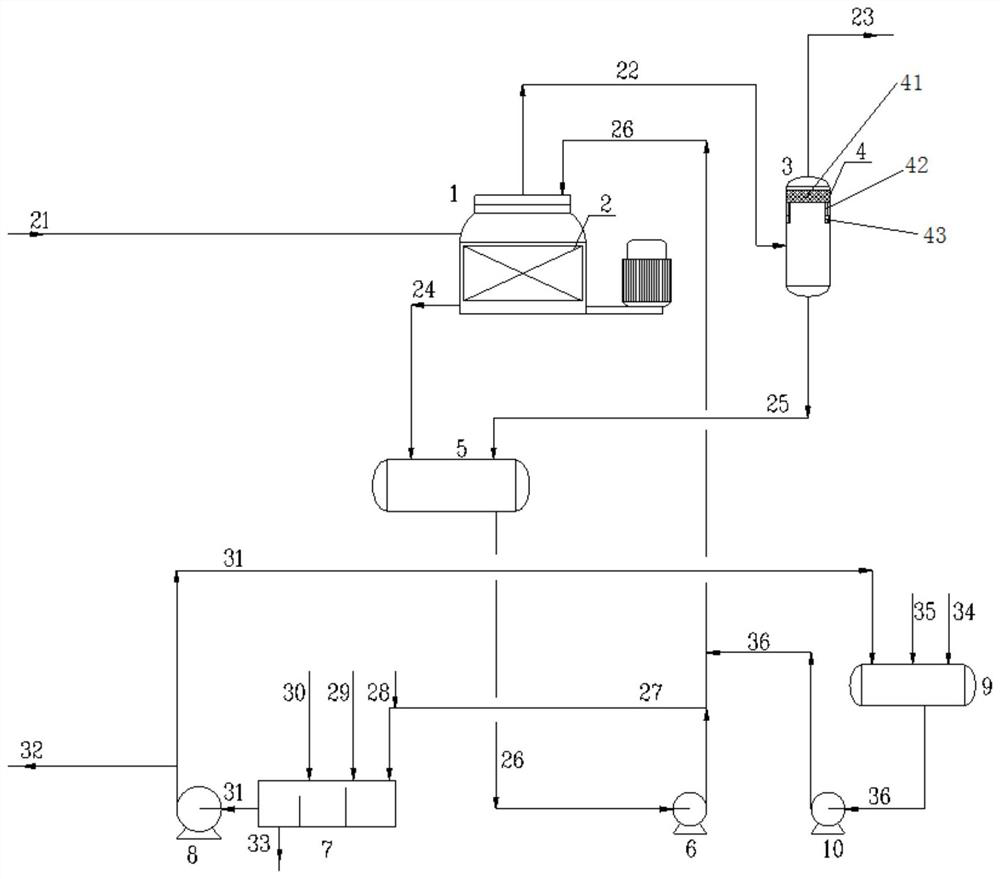

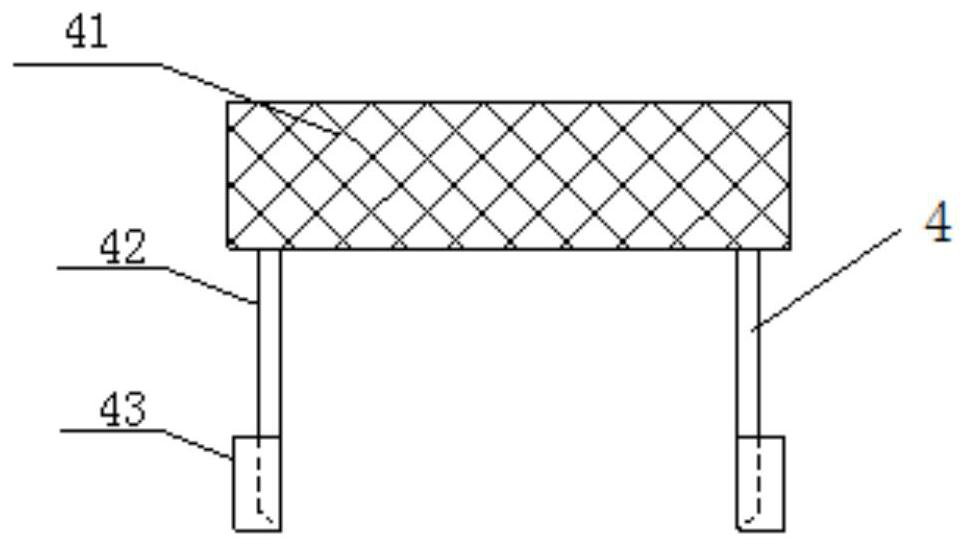

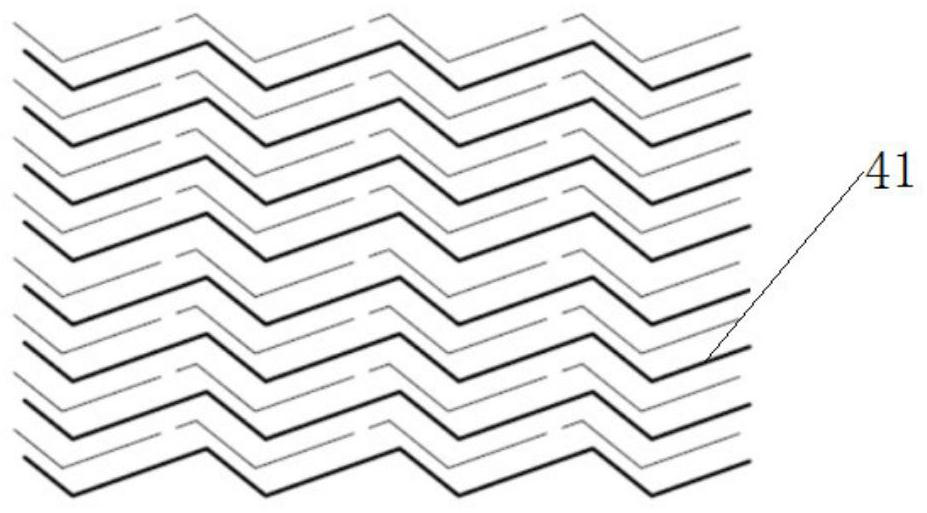

[0034] Such as Figure 1-3 As shown, the present invention uses a high-gravity rotating bed combined with a proprietary desulfurizer to perform one-step wet desulfurization of sulfur-containing gas. The supergravity rotating bed technology is a new technology that uses a hypergravity envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com