Special orange-resistant belt adhesive film for laser card and preparation method of special orange-resistant belt adhesive film

A card and belt technology, used in adhesives, film/sheet release coatings, film/sheet adhesives, etc., can solve the problem of unusable laser materials, and ensure the stability of film coverage and laser effect. Sufficient, save the effect of re-coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare the special anti-orange belt adhesive film for laser card through the following steps 1

[0039] Step (1) earlier with epoxy value 0.4, 30 parts of diphenol group propane epoxy resins of epoxy resin diphenol group propane epoxy resin of molecular weight 300, 20 parts of HEA of acrylate, 30 parts of BA and 10 parts of CAC of cosolvent Add to the container and stir evenly, then heat up to 110°C, add 1 part of triethylamine as catalyst, stir and react at 120 rpm for 6 hours, then cool down to 30°C, add 25 parts of diluent PMPTA, 20 parts of filler meteorological silica and initiator 1 part of 1173, stirred at 300 rpm for 0.5 hours to obtain the mirror layer material, and coated in two layers;

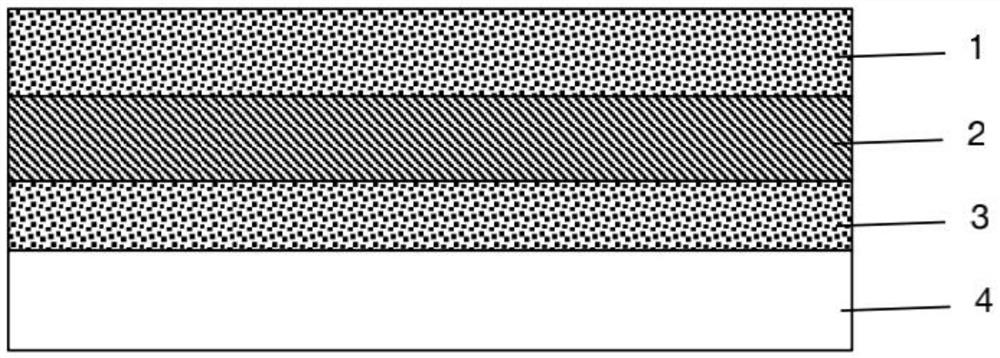

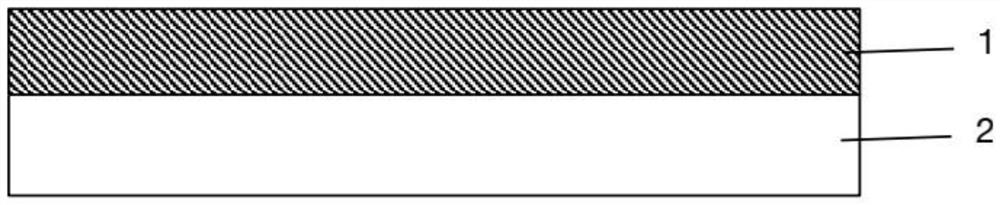

[0040]Step (2) Coating the first and second mirror layers on both sides of the substrate layer respectively, irradiating with ultraviolet light (UV) and heating and curing, and then coating an adhesive layer on the surface of any mirror layer and drying it to obtain a laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com