Vegetable oil-based low-halogen environment-friendly printing ink and preparation method thereof

A vegetable oil-based, environmentally friendly technology, applied in the ink field, can solve the problems of poor printing adaptability, slow ink drying speed, etc., and achieve excellent printing performance, not easy to stack, and widely applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

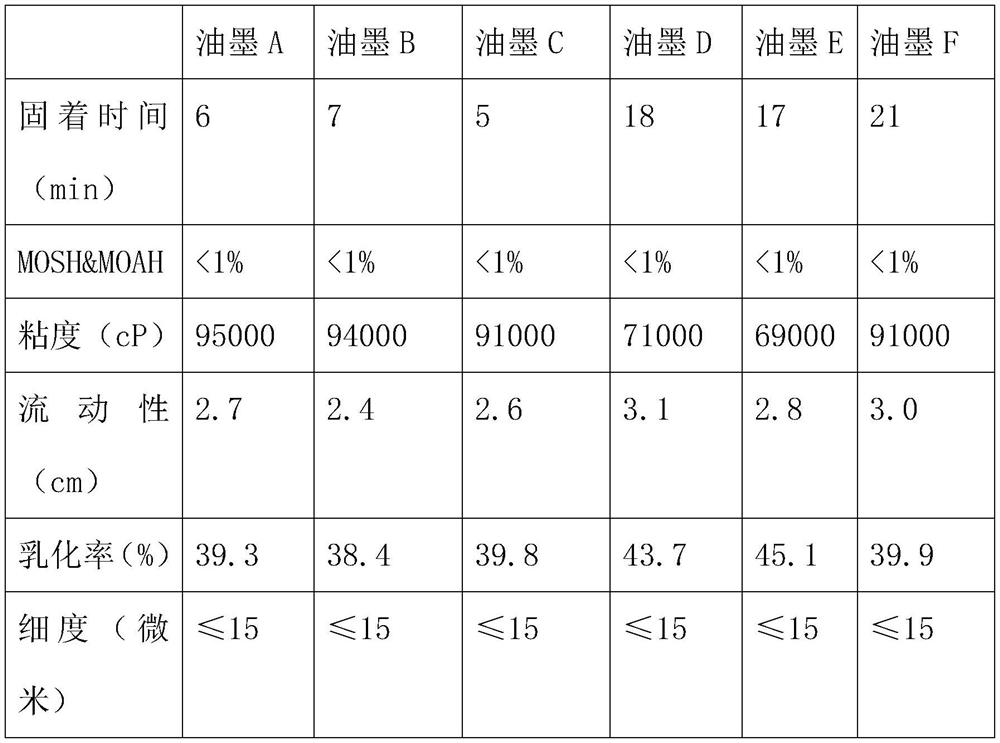

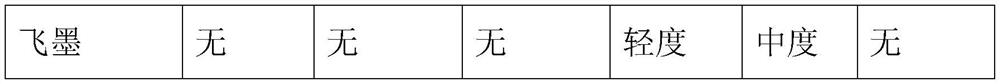

Examples

specific Embodiment 1

[0049] Specific example 1: 20 parts of pigment particles, 4 parts of polyethylene wax, 10 parts of binder, 10 parts of soybean oleate A, 0.4 parts of cobalt desiccant, and 1 part of dispersant. The binder consists of 38 parts of modified short oil alkyd resin, 26 parts of tung oil, 13 parts of soybean oil, 25 parts of methyl soybean oil B, 0.6 parts of gelling agent and 2,6-di-tert-butyl-4-methyl Made from 0.2 parts of phenol. The modified short oil alkyd resin consists of 15 parts of soybean oil fatty acid, 15 parts of n-butyl methacrylate, 25 parts of refined soybean oil, 25 parts of glycerin, 20 parts of phthalic anhydride, 2 parts of lithium hydroxide and initiator The preparation is made in 4 parts.

[0050] The preparation steps (1) of specific embodiment 1, dispersing and compounding: the pigment particles, polyethylene wax, connecting material, methyl soybean oleate A, cobalt drying agent and dispersing agent of the above-mentioned parts by weight are added in the hig...

specific Embodiment 2

[0053] Specific example 2: 25 parts of pigment particles, 5 parts of polyethylene wax, 15 parts of binder, 12 parts of methyl soybean oleate A, 0.5 parts of cobalt desiccant, and 1.5 parts of dispersant. The binder consists of 38 parts of modified short oil alkyd resin, 26 parts of tung oil, 13 parts of soybean oil, 25 parts of methyl soybean oil B, 0.6 parts of gelling agent and 2,6-di-tert-butyl-4-methyl Made from 0.2 parts of phenol. The modified short oil alkyd resin consists of 15 parts of soybean oil fatty acid, 15 parts of n-butyl methacrylate, 25 parts of refined soybean oil, 25 parts of glycerin, 20 parts of phthalic anhydride, 2 parts of lithium hydroxide and initiator The preparation is made in 4 parts.

[0054] The preparation step (1) of specific embodiment 2, dispersing and compounding: the pigment particle, polyethylene wax, connecting material, methyl soybean oleate A, cobalt desiccant and dispersant of above-mentioned parts by weight are added in the high-spe...

specific Embodiment 3

[0057] Specific example 3: 30 parts of pigment particles, 6 parts of polyethylene wax, 20 parts of binder, 15 parts of methyl soybean oleate A, 0.6 parts of cobalt desiccant, and 2 parts of dispersant. The binder consists of 38 parts of modified short oil alkyd resin, 26 parts of tung oil, 13 parts of soybean oil, 25 parts of methyl soybean oil B, 0.6 parts of gelling agent and 2,6-di-tert-butyl-4-methyl Made from 0.2 parts of phenol. The modified short oil alkyd resin consists of 15 parts of soybean oil fatty acid, 15 parts of n-butyl methacrylate, 25 parts of refined soybean oil, 25 parts of glycerin, 20 parts of phthalic anhydride, 2 parts of lithium hydroxide and initiator The preparation is made in 4 parts.

[0058] The preparation steps of specific example 3: (1), dispersing and compounding: the pigment particles, polyethylene wax, binder, methyl soybean oleate A, cobalt drying agent and dispersing agent of the above-mentioned parts by weight are added in the high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com