Rural sewage aeration treatment device

A technology for treatment device and rural sewage, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc. Manual cleaning is easy and the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

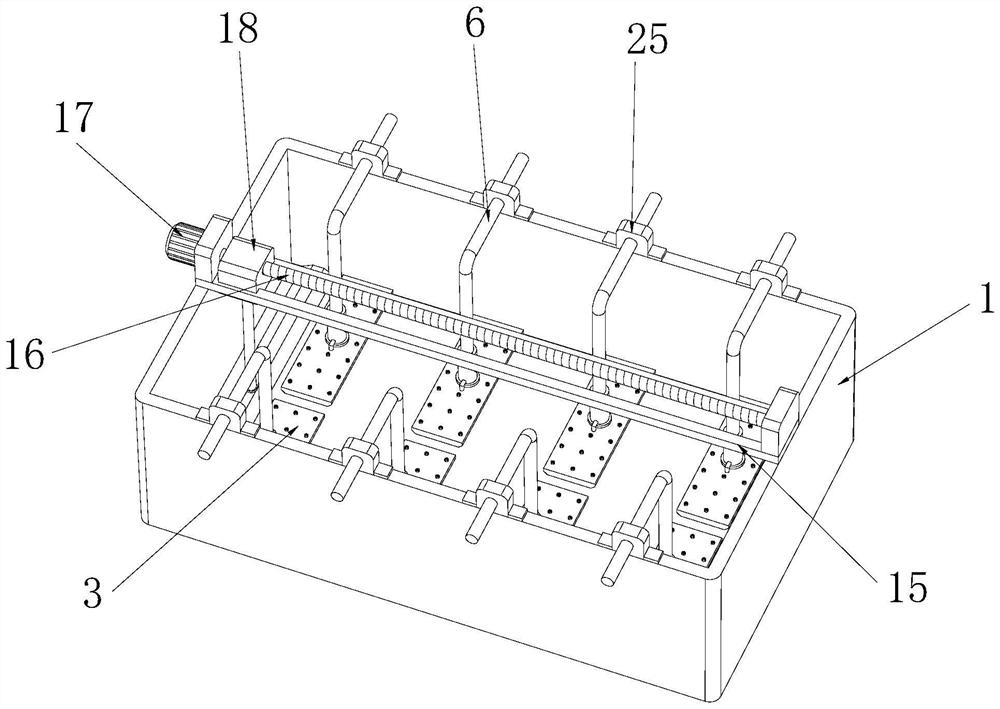

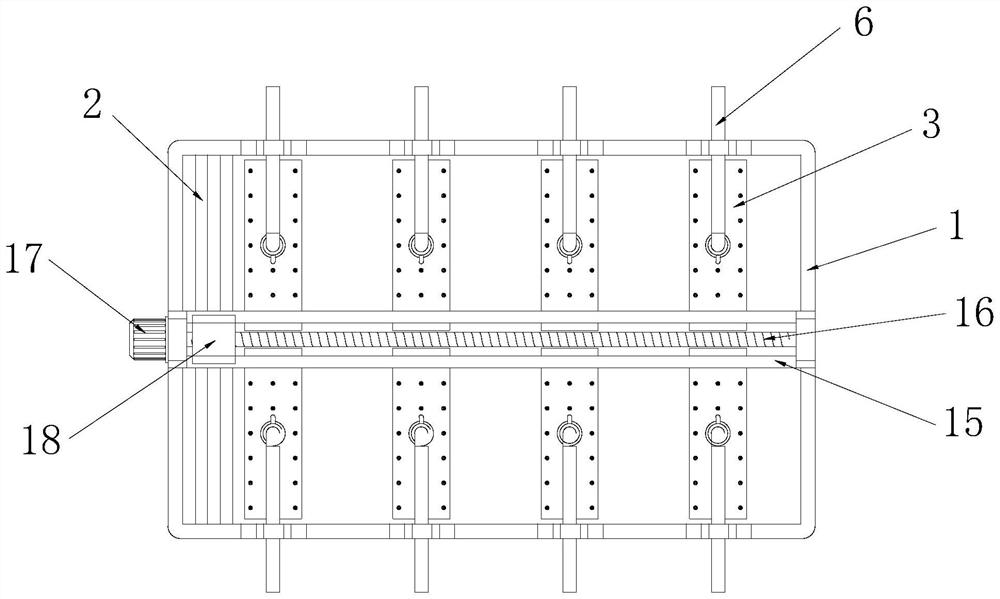

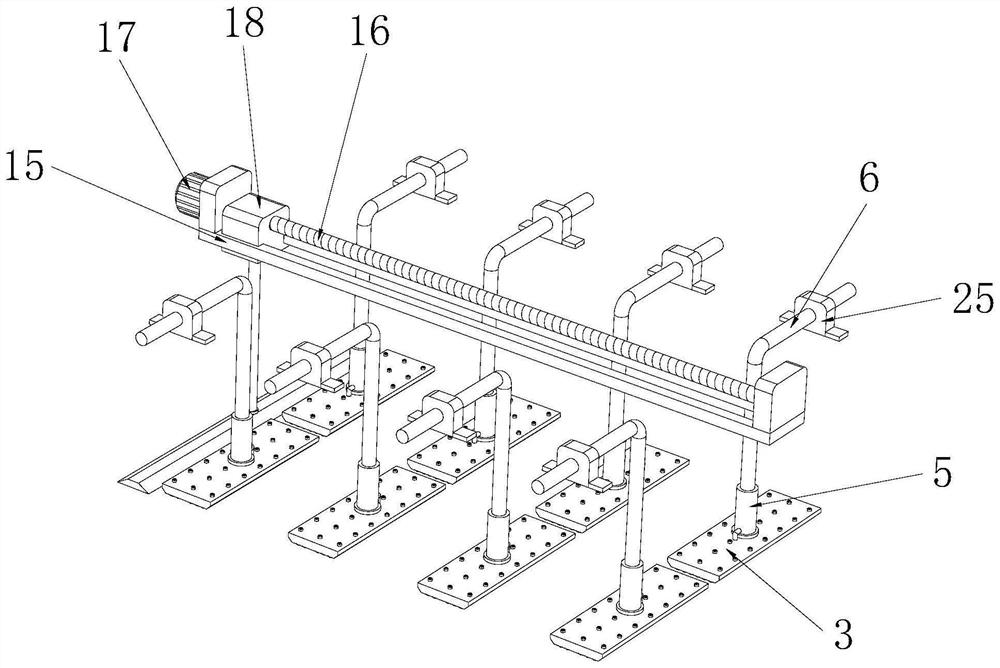

Embodiment 1

[0031] see Figure 1~5 , in an embodiment of the present invention, an aeration treatment device for rural sewage, comprising an aeration tank 1, a shovel plate 2 is provided at the bottom of the inner cavity of the aeration tank 1, and the bottom wall of the shovel plate 2 is in contact with the The inner wall of the bottom of the aeration tank 1 is in contact with each other. The aeration tank 1 is provided with a driving mechanism for driving the shovel plate 2 to move relative to the aeration tank 1. The aeration tank 1 is fixedly equipped with an air inlet pipe 6. The bottom end of the air inlet pipe 6 is provided with a connecting cylinder 5, the connecting cylinder 5 is slidingly fitted with the air inlet pipe 6, and the air inlet pipe 6 is elastically connected with the connecting cylinder 5, and the bottom end of the connecting cylinder 5 is fixed An aeration plate 3 is installed, and the aeration plate 3 communicates with the air inlet pipe 6 through the connecting c...

Embodiment 2

[0036] see Figure 4-8 , in the embodiment of the present invention, a piston 8 is fixedly installed at the bottom end of the intake pipe 6, and the piston 8 is slidingly fitted with the connecting cylinder 5, and the inner cavity of the connecting cylinder 5 is provided with a connecting pipe 9. The top end of the connecting pipe 9 is fixedly connected to the bottom wall of the piston 8, the bottom end of the connecting pipe 9 is fixedly connected to the top wall of the aeration plate 3, and a through hole is opened on the piston 8, and the connecting The top of the pipe 9 communicates with the inlet pipe 6 through a through hole, and the bottom end of the connecting pipe 9 communicates with the inner cavity of the aeration head 4; a spring 10 is arranged in the connecting cylinder 5, and the The top end of the spring 10 is fixedly connected to the bottom wall of the piston 8, the bottom end of the spring 10 is fixedly connected to the top wall of the aeration plate 3, the sp...

Embodiment 3

[0039] see Figure 9 and Figure 10 , in the embodiment of the present invention, one side of the bottom end of the aeration tank 1 is fixedly equipped with an impurity tank 20, and the top of the impurity tank 20 is provided with an opening, and the top wall of the impurity tank 20 is in contact with the aeration tank 1 The inner wall of the bottom is flush; the top of the impurity tank 20 is slidably installed with a cover 21, which is elastically connected to the inner wall of the aeration tank 1, and the top of the cover 21 is fixedly installed with a connection Rod 23, the connecting rod 23 is arranged in an L shape, and the end of the connecting rod 23 away from the cover 21 is fixedly equipped with a push plate 24, and the push plate 24 is arranged on the top side of the cover 21 close to the motor 17, When the push rod 19 moves toward the impurity tank 20, the push rod 19 pushes the push plate 24 to move to the right, thereby pushing the cover 21 to move to the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com