Miniature manipulator for logistics express carrying

A manipulator and miniature technology, applied in the field of manipulators, can solve the problems affecting the normal gripping and slipping of manipulators, and achieve the effect of preventing noise and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

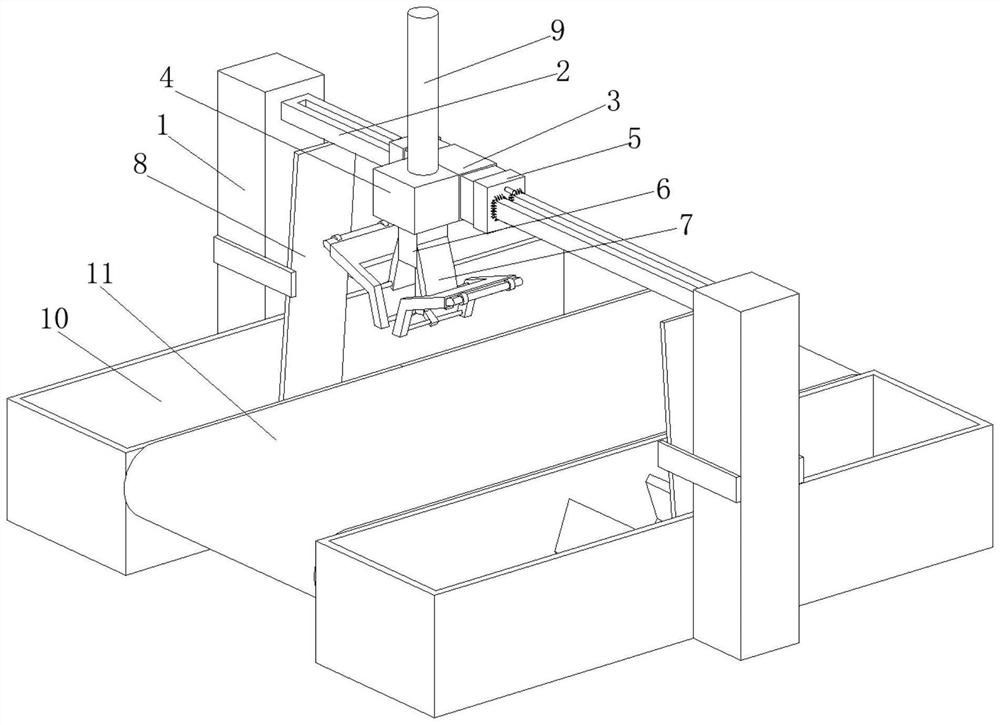

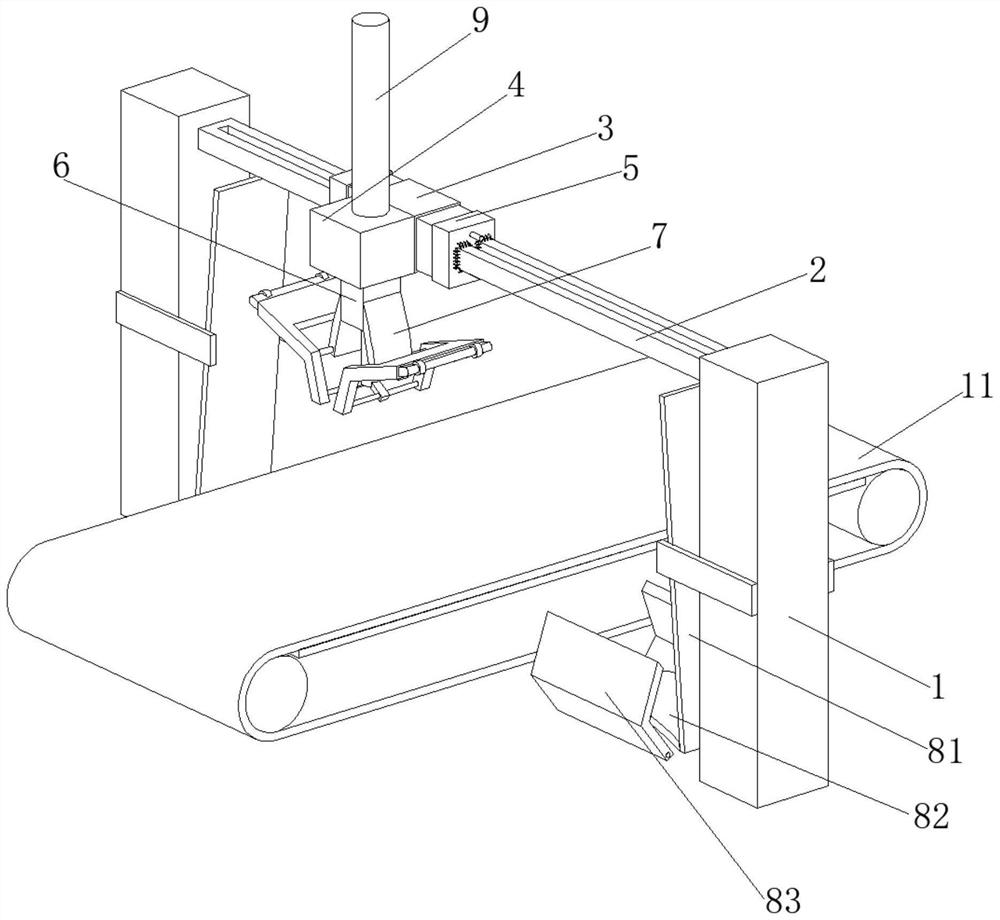

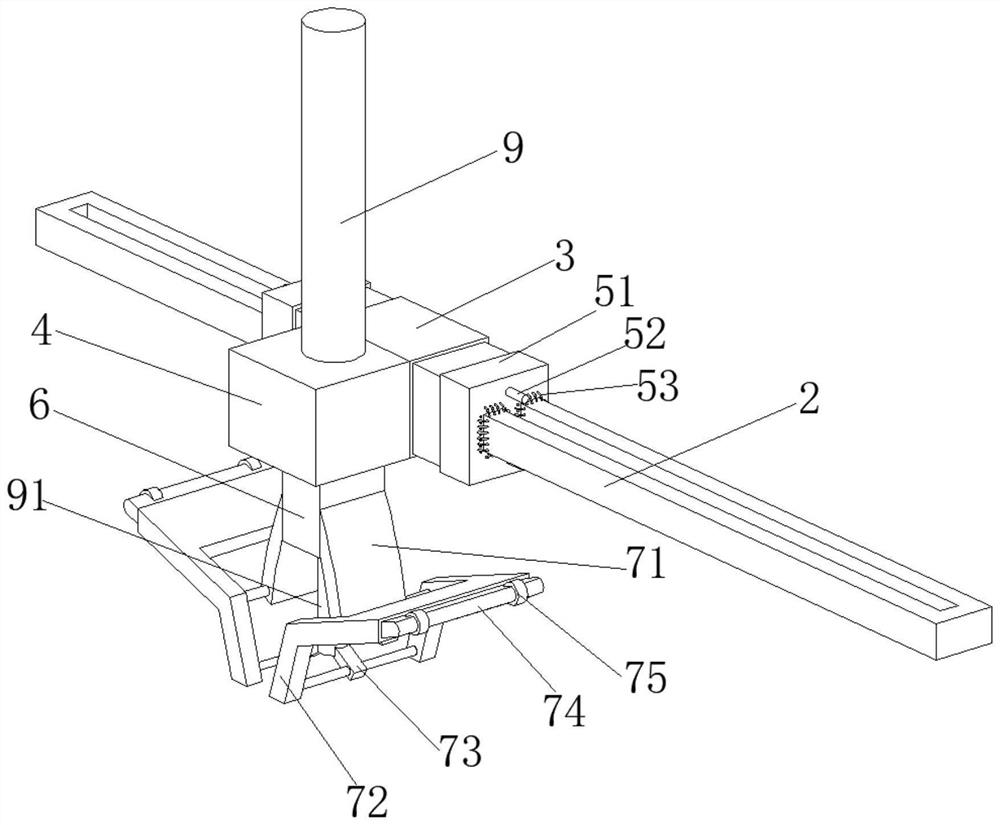

[0028] A kind of micro manipulator for logistics express handling, such as Figure 1-Figure 6 As shown, it includes the manipulator body. The manipulator body includes a slide rail 2, a linear motor 3, a fixed block 4, a support block 6, a clamping device 7, a cylinder 9, and a push rod 91. The linear motor 3 is slidably connected to the surface of the slide rail 2. , the right side of the fixed block 4 is fixedly connected with the left side of the linear motor 3, the bottom end of the cylinder 9 is fixedly connected with the top of the fixed block 4, the top of the support block 6 is fixedly connected with the bottom of the fixed block 4, and the surface of the support block 6 A clamping device 7 is provided, and the output end of the cylinder 9 is fixedly connected to the top of the push rod 91; the clamping device 7 includes a transmission plate 71, and the side of the transmission plate 71 away from the support block 6 is connected with a splint 72 through a connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com