Automatic steel core removing machine

A steel core, automatic technology, applied in the attachments of sawing machines, manufacturing tools, sawing machine devices, etc., can solve the problems of the shape and angle of the steel core of the rubber strip, the processing effect is not ideal, and the waste of human resources, etc., to achieve a wide range of applications. , ingenious structure, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

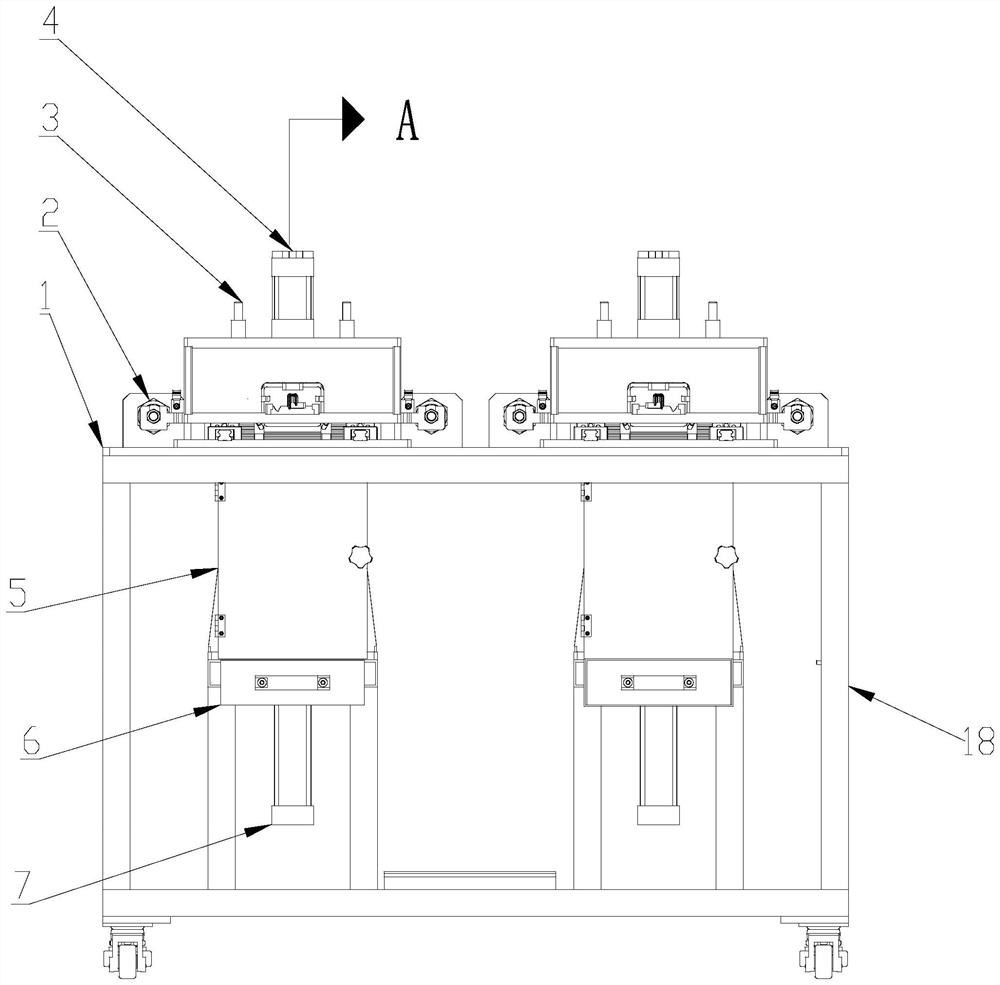

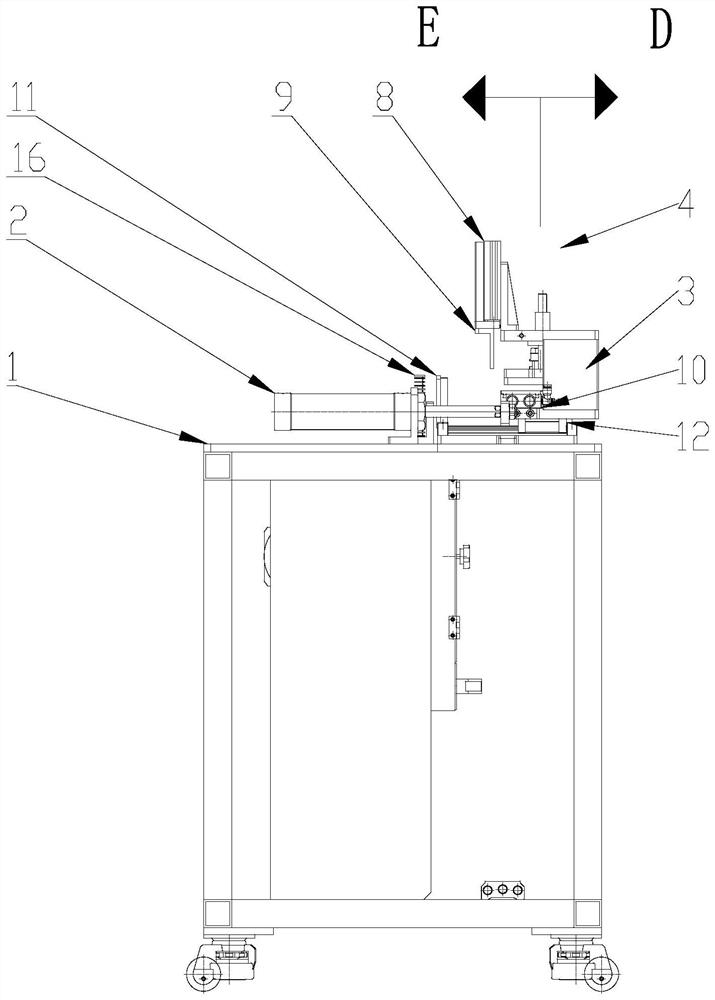

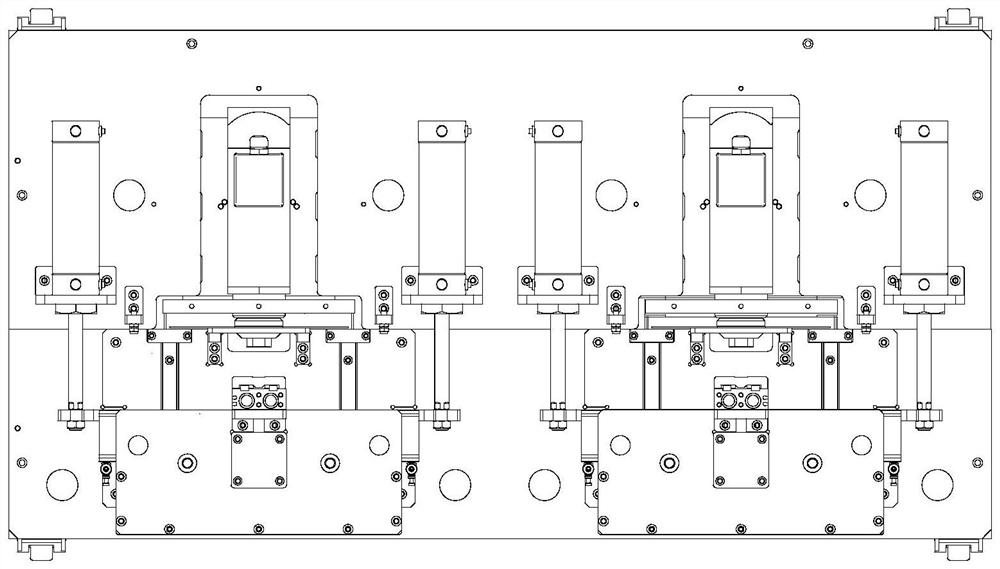

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1~7 As shown, the present invention is an automatic steel core removal machine, comprising a frame 18, a frame top plate 1 is arranged on the upper end of the frame 18, and at least one group of rubber strip positioning mechanisms are arranged on the frame top plate 1, so as to realize steel core removal. The core is compressed in the vertical direction and clamped in the horizontal direction, and the rubber strip positioning mechanism is provided with a rubber strip front stop mechanism to limit the steel core.

[0028] A longitudinal movement mechanism is also arranged on the top plate 1 of the frame, and the longitudinal movement mechanism can drive the rubber strip positioning mechanism to reciprocate.

[0029] A rubber strip peeling mechanism is installed in front of the longitudinal moving mechanism.

[0030] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com