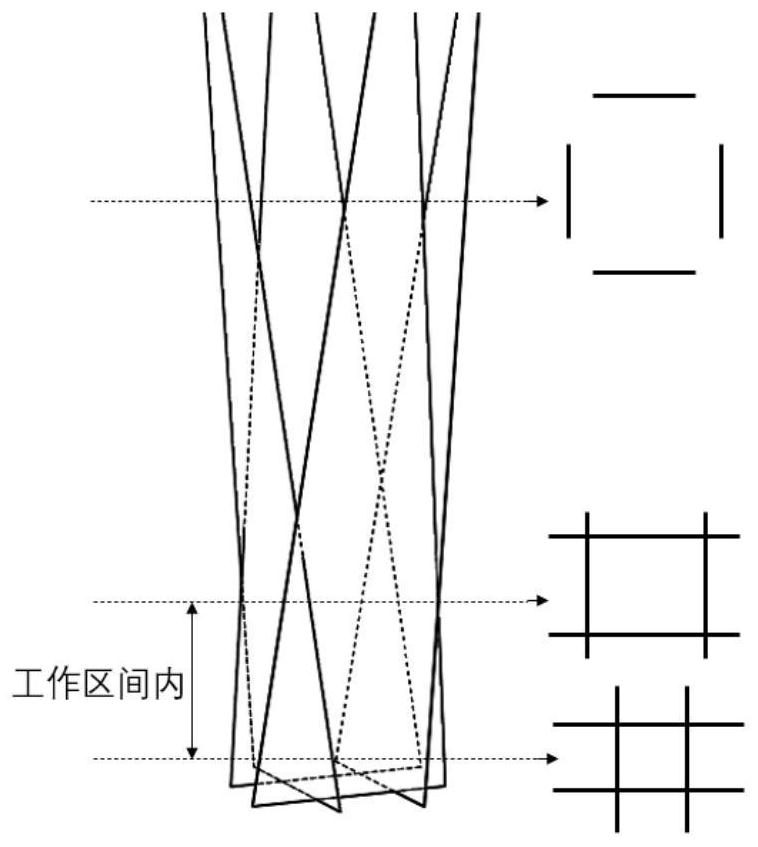

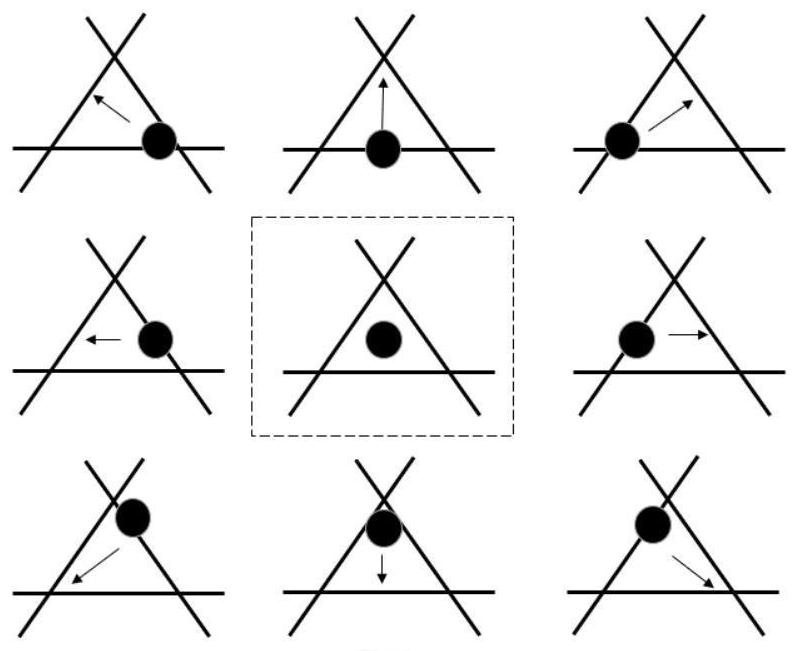

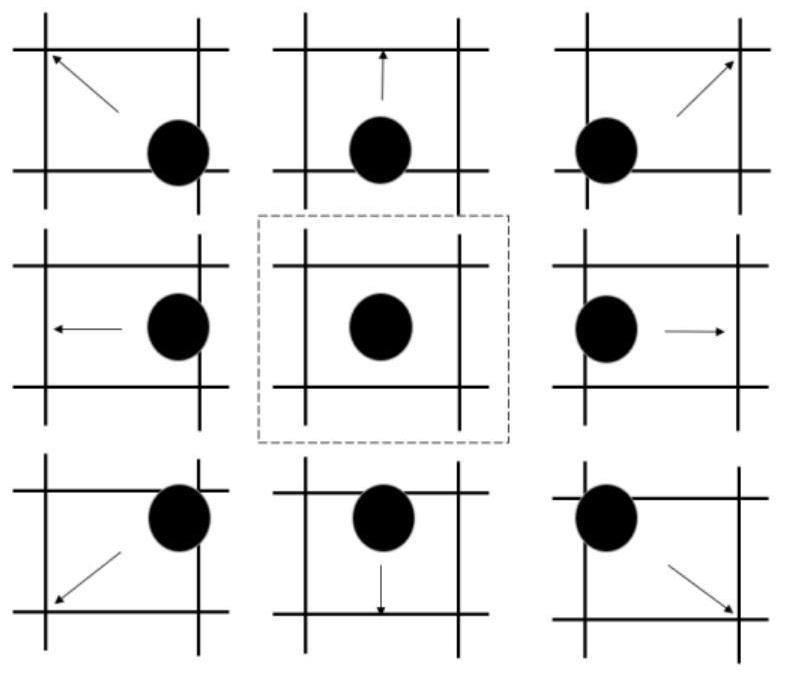

Multi-line laser sensing closed layout structure, scanning splicing method and gluing scanning method

A multi-line laser, layout structure technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of high degree of freedom of equipment, spatial interference, complex programming, etc., to achieve the effect of convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0048] Figure 4 , Figure 5 A glue-scanning embodiment of the invention using a six-axis industrial robot is shown.

[0049] see Figure 4 As shown, the gluing scanning method comprises the following steps:

[0050] ⑴ Make the mounting parts, and install the four calibrated line laser sensors evenly to form a closed quadrilateral;

[0051] ⑵Install the mounting parts to the end of the robot, complete the hand-eye matrix calibration of each line laser and the end of the robot, use the standard sphere calibration method, move the robot end posture respectively, move the laser line to the standard sphere, and take 20 poses for each sensor , record the sensing data and robot attitude data, and calculate simultaneously to obtain the sensing hand-eye matrix T n ;

[0052] ⑶ Along the trajectory of the glue road, the end of the translation is programmed to write t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com