Isolation type LED packaging structure

An LED packaging and isolation technology, applied in lighting devices, gas/waterproof devices, components of lighting devices, etc., can solve the problems of inability to electrostatically insulate, inconvenient to disassemble, and easy to enter into the interior of the shell, etc. Good isolation and sealing effect, good insulation effect, convenient installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

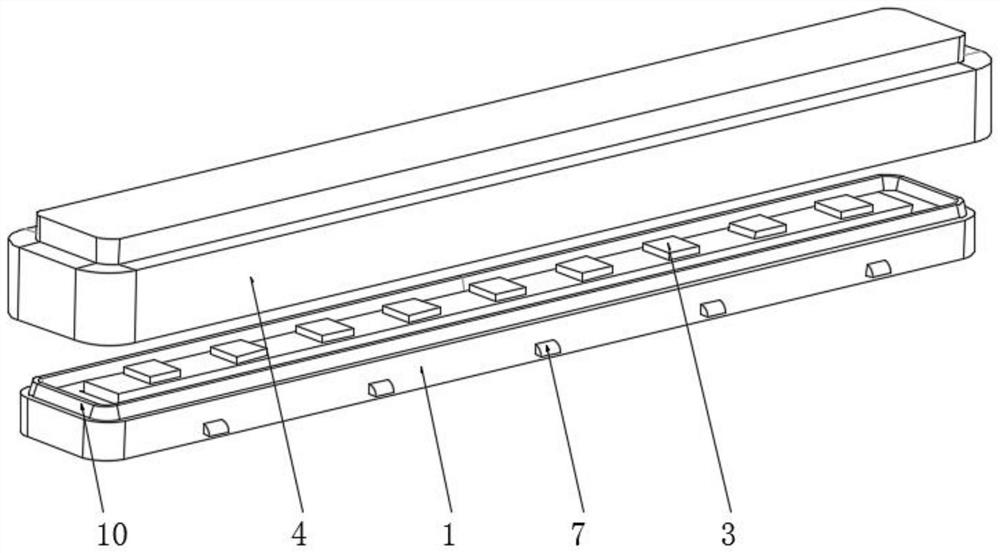

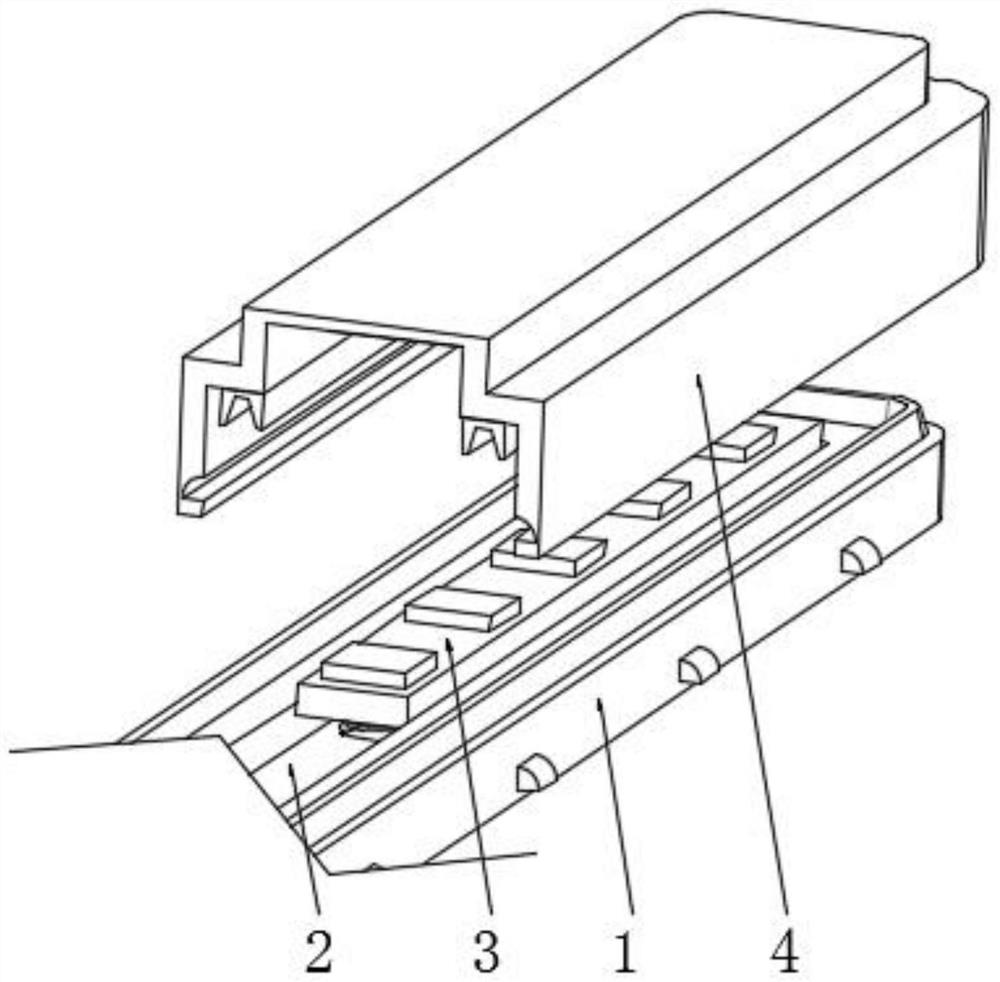

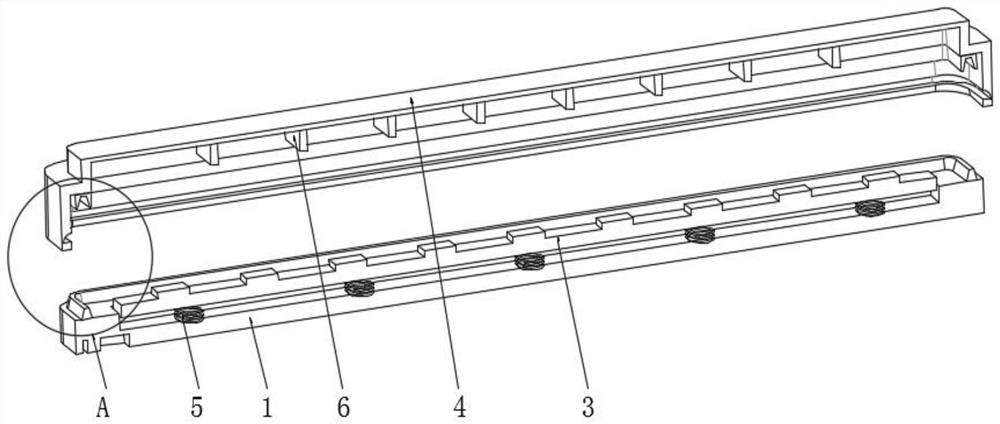

[0026] see Figure 1-7 , in an embodiment of the present invention, an isolated LED packaging structure includes an isolation base plate 1, an LED board chute 2 is opened on the upper side of the isolation base plate 1, and an LED board body 3 is slidably connected to the inner side of the LED board chute 2, and the LED The lower side of the board body 3 is connected with five buffer springs 5 at equal intervals, and one end of the five buffer springs 5 is connected to the bottom end of the LED board chute 2, and an upper case 4 is arranged above the isolation base plate 1, and the upper case The inner side surface of 4 is located at the lower side edge and is provided with a case slot 8, and the inner upper end of the upper case 4 is fixed with eight compression isolation plates 6 at equal intervals, and the two sides of the isolation bottom plate 1 correspond to the case slot 8. There are ten engaging inserting rods 7 inserted symmetrically at the position, and the ten e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com