Telescopic steel bar cloth hanging trolley

A telescopic and cloth trolley technology, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of increased construction safety risks, large arched gantry, and poor road passability, so as to reduce the difficulty of transition , reduce construction costs, and improve passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

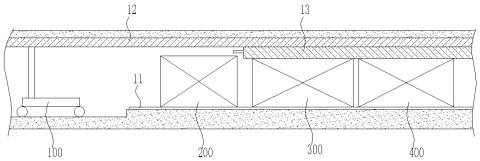

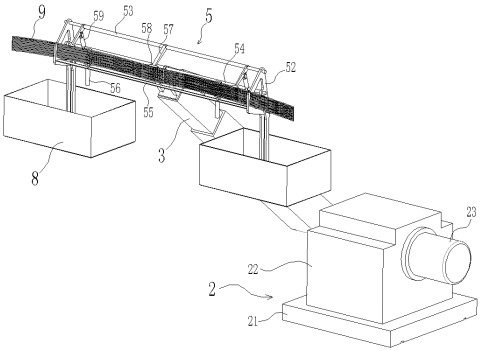

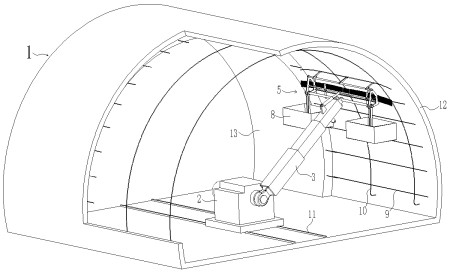

[0033] A telescopic steel hanging cloth trolley, such as Figure 2-3 As shown, a chassis 2 for walking in a tunnel 1 is included. Usually all lay construction track 11 in tunnel 1, so chassis 2 is provided with the traveling wheel driven by traveling motor, and traveling wheel can walk along construction track 11, moves by construction track 11. The chassis 2 is hinged with a telescopic arm 3, and the telescopic arm 3 is connected with a reinforcement hanger 5. Specifically, the chassis 2 is provided with a rotating arm motor 23 with a brake function. After being decelerated by a reducer, the rotating arm motor 23 can make the telescopic arm 3 rotate in the cross section of the arch of the tunnel 1 under the control of the control system. It should be noted that the arm motor 23 can also be replaced by a rotary oil cylinder.

[0034] Such as figure 2 As shown, in this embodiment, the telescopic boom 3 is a three-section telescopic boom 3, and two oil cylinders are arranged...

Embodiment 2

[0040] Different from Example 1, as Figure 5 As shown, the hanging cloth frame 6 and the third rotating cylinder 7 are hinged at both ends of the hinge shaft 51 , and the third rotating cylinder 7 is used to push the hanging cloth frame 6 to rotate relative to the telescopic arm 3 .

[0041] Such as Figure 6 As shown, the cloth hanger 6 includes a frame-shaped frame body 61 on which a reel, a pressing roller 62 , a glue applicator 65 and a movable nail gun 64 are arranged. Specifically, the glue applicator 65 is fixed on one side of the frame body 61, and is used for applying glue to the side of the waterproof cloth. When hanging the cloth, the glue applicator 65 staggers and bonds the sides of the two waterproof cloths together, which can play a role of sealing. It is worth noting that the glue applicator 65 can be replaced by a climbing welding machine. The climbing welding machine does not need to be glued. The climbing welding machine has a roller that can be heated. W...

Embodiment 3

[0048] Different from Embodiment 1, the chassis 2 is composed of a machine base 21 and a cabinet 22 , and the machine base 21 has traveling wheels and can walk along the construction track 11 . The chassis 22 is located above the base and can rotate in a horizontal direction relative to the base 21 . The telescopic arm 3 is rotatably arranged on the casing 22, and the casing 22 is also provided with a rotating arm motor 23, which drives the telescopic arm 3 to rotate after being decelerated by a reducer.

[0049] Such as Figure 8 As shown, arched steel bars 10 are arranged in the receiving groove of the steel bar hanger 5 . After the cabinet 22 is rotated by 90°, the arched steel bar 10 is located in the cross section of the tunnel. At this time, the arched steel bar 10 can be grasped by the rotating arm 57 to assist in laying the arched steel bar 10 . Apparently, such assistance saves time and effort than manually laying the arched steel bar 10 .

[0050] It can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com