Plunger device

A technology of plunger and main body, which is applied in the field of oil and gas exploitation, can solve problems such as the bulky structure of the wellhead blowout preventer, and achieve the effect of expanding the application depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

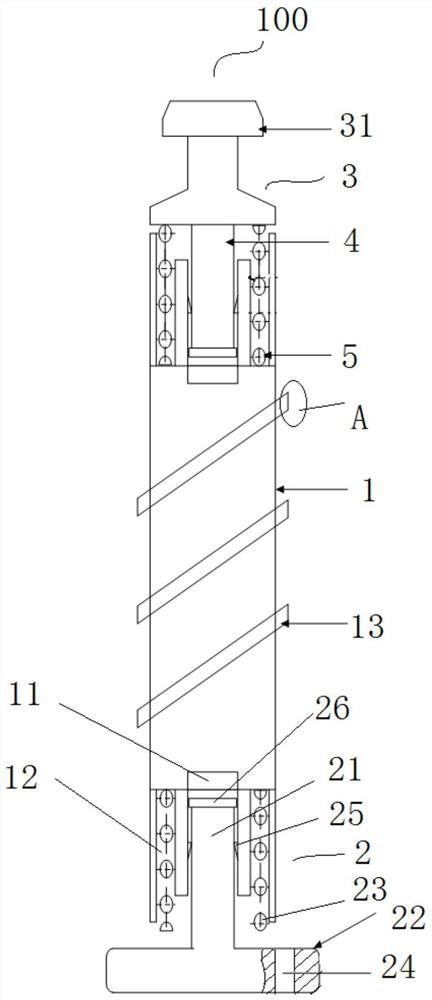

[0026] figure 1 A plunger device 100 according to the invention is shown. Such as figure 1 As shown, the plunger device 100 includes a plunger body 1 and a buffer 2 . Wherein, the plunger body 1 is columnar. The buffer 2 is arranged at the lower end of the plunger body 1 for buffering. During the falling process of the plunger device 100 , the buffer 2 is used to be seated at the clamping position of the oil pipe, so as to achieve the purpose of buffering. By setting the buffer 2, the plunger device 100 can be directly injected into the tubing without pre-installing the downhole retainer. Therefore, the plunger device 100 with the above structure can avoid the use of the downhole retainer and the operation of running in, and thus expand the application depth of the plunger device 100, so that the plunger device 100 is not only suitable for vertical wells with pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com