Continuous while-drilling in-situ test power driving device and construction method

An in-situ testing and power-driven technology, applied in the direction of measurement, drill pipe, drill pipe, etc., can solve the problems of limited test depth and difficulty in meeting the development and utilization of deep underground space, and achieve saving construction procedures, increasing portability, and structural design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

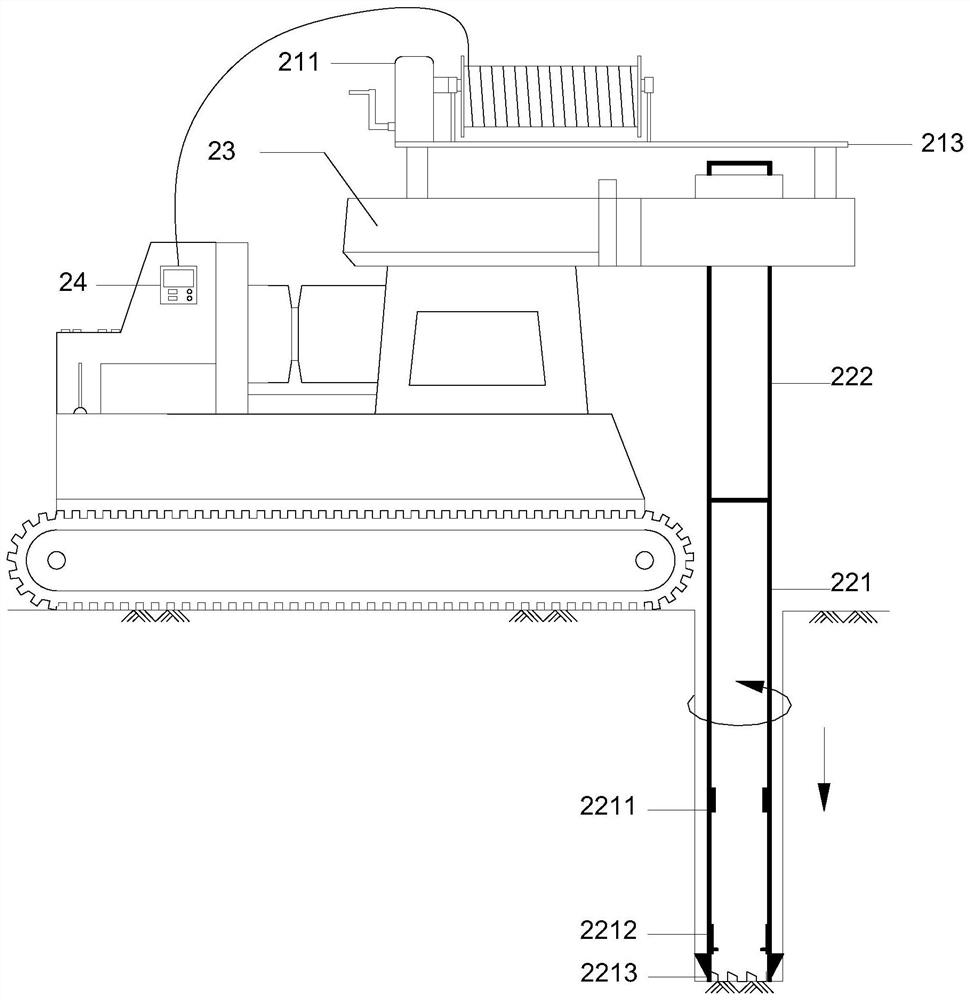

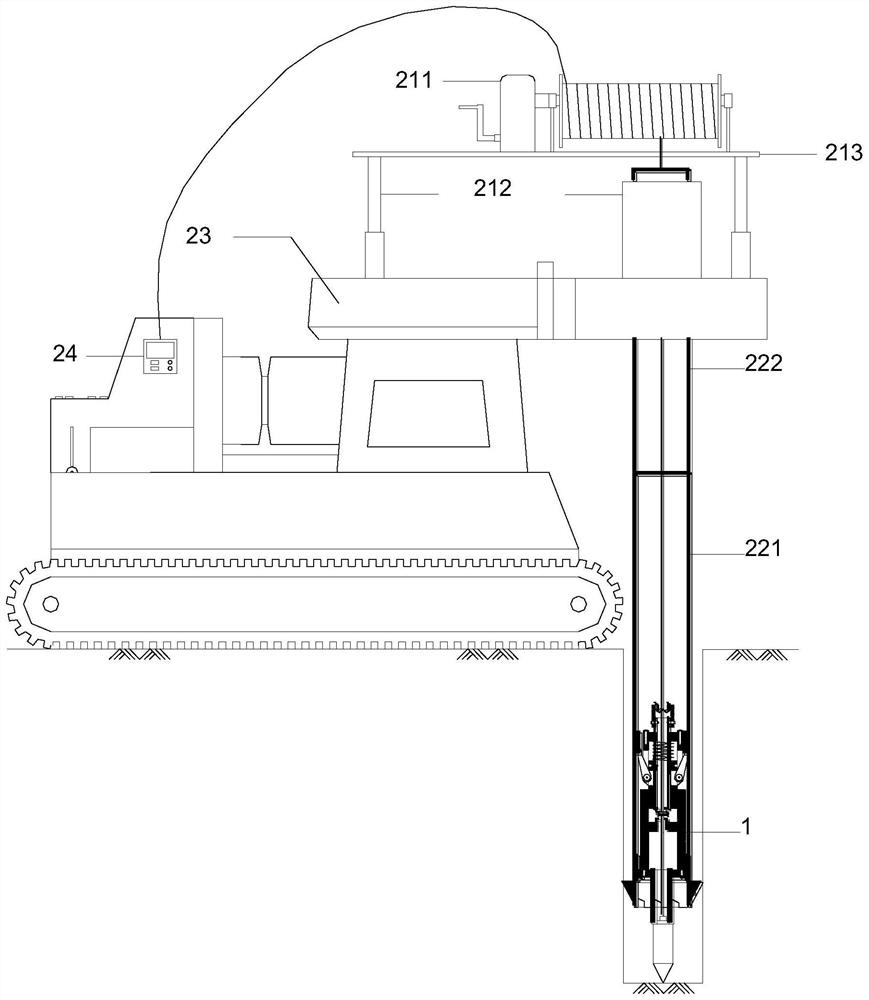

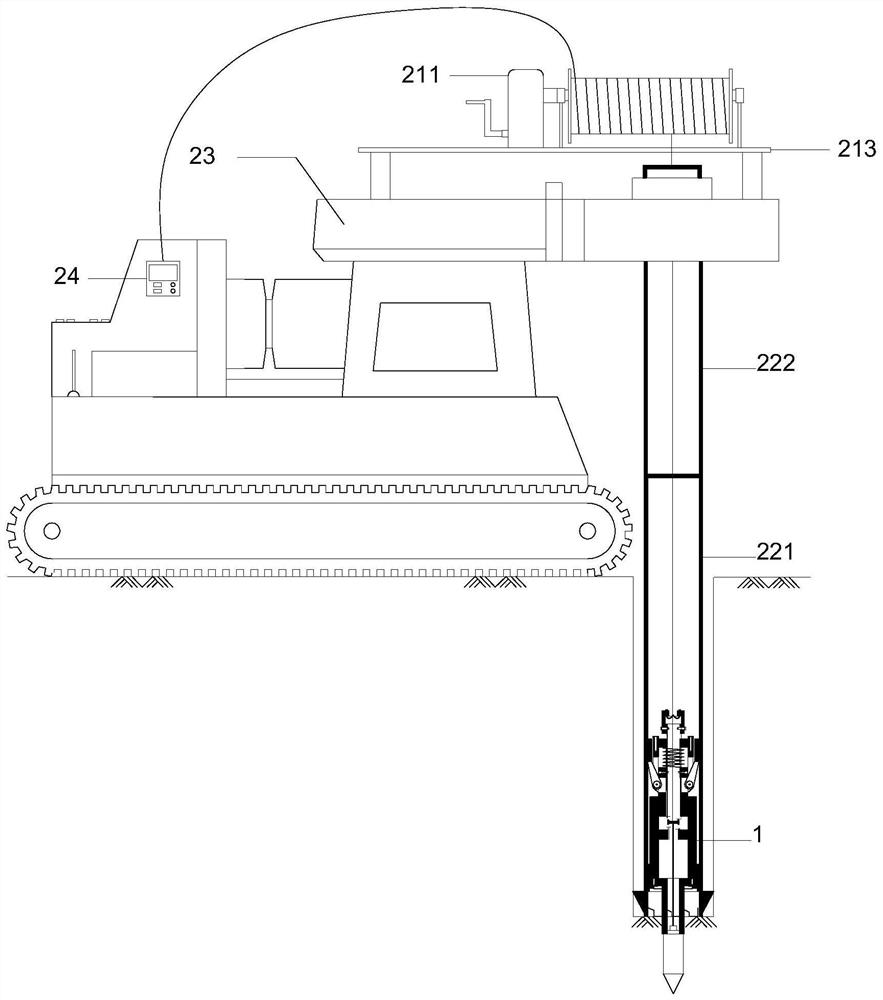

[0039] see Figure 1-11 , a driving device for continuous in-situ testing while drilling, comprising: a drill pipe 22 capable of accommodating and supporting an in-situ test assembly inside; a drilling device 2 with a clamping device for the drill pipe; located on the drilling rig, and capable of An elevating platform that lifts together with the drill pipe clamping device; one end is connected to the in-situ test assembly and can penetrate the cable 14 inside the drill pipe 22; The cable guide device for guiding the cable 14; the claw 132 that is coaxial with the in-situ test assembly and can move axially relative to the in-situ test assembly; the claw 132 can be opened / folded upward; the claw 132 is retracted and reset The jaw retracting device; located above the jaw 132, coaxial with the in-situ test assembly, and a slide block that can move axially relative to the in-situ test assembly; located on the inner wall of the drill pipe 22, the lower end is used to resist Hold t...

Embodiment 2

[0056] This case is the same as the first embodiment except for the cable storage device. For details, see Figure 6-11 .

[0057] The cable storage device in this case includes a slide rail 213 , a pulley 214 , a fuselage hoisting device 215 , and a lifting platform 216 . A pulley 214 is arranged on the slide rail 213, and the pulley 214 can move back and forth along the slide rail 213 to ensure that the cable is in a vertical state during the in-situ test. The pulley 214 is located on the same plane as the fuselage hoisting device 215 and the central axis of the drill pipe; one end of the fuselage hoisting device 215 is connected to the in-situ test assembly, and the other end is connected to the signal receiving device 24, which can be stored manually or electrically. The height of the cable and hoisting device 215 is lower than the top of the drill pipe, and the direction of the force is transformed through the pulley 214; the lifting platform 216 can be lifted at a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com