Air bag type fiber and preparation method thereof

An airbag type, fiber technology, applied in the fiber field, can solve the problems of escape and the decline of the insulation performance of the hollow fiber, achieve the effects of good bulkiness and resilience, improve the thermal insulation performance, and improve the air retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

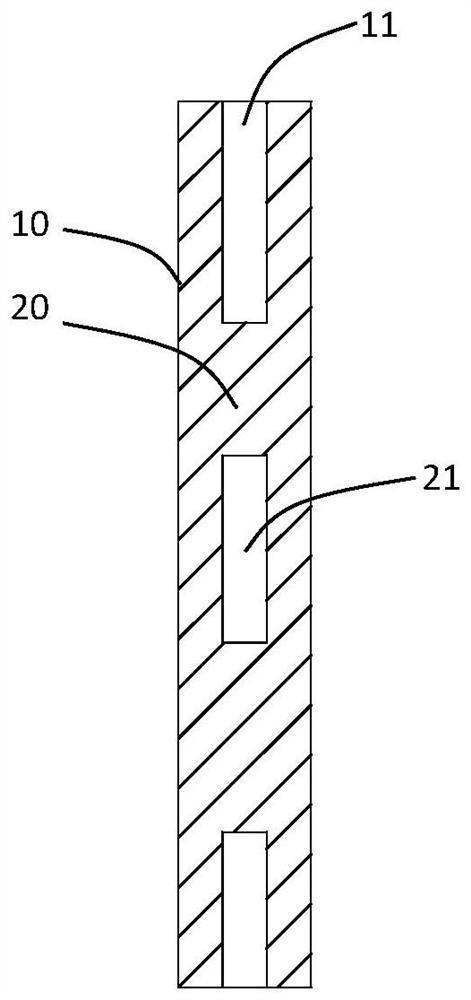

[0015] Such as figure 2 As shown, the airbag fiber of the present invention includes a fiber body 10, a hollow portion 11 is arranged in the middle of the fiber body 10, and a plurality of separation layers 20 are arranged at intervals in the hollow portion 11, and the separation layer 20 separates the hollow portion 11 to form a plurality of volumes capable of Freely variable air bag 21. The airbags 21 are arranged in the hollow portion 11 in an irregular manner. Thus, by arranging the airbags 21 in the hollow portion 11 in a bionic manner, it is possible to prevent gas from escaping, improve the air retention capacity inside the fiber, and then improve the heat retention capacity of the fiber.

[0016] The fiber body 10 and the separation layer 20 are solidified from polymer melt.

[0017] The above-mentioned polymer melt can be polyester,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com