3D printing resin for antibacterial wear-resistant shoes

A 3D printing and resin technology, applied in the field of 3D printing, can solve the problems of weak wear resistance and stain resistance, brittle 3D printing materials, and inapplicability to 3D printing footwear, etc., to achieve the effect of preventing athlete's foot and preventing fabric infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

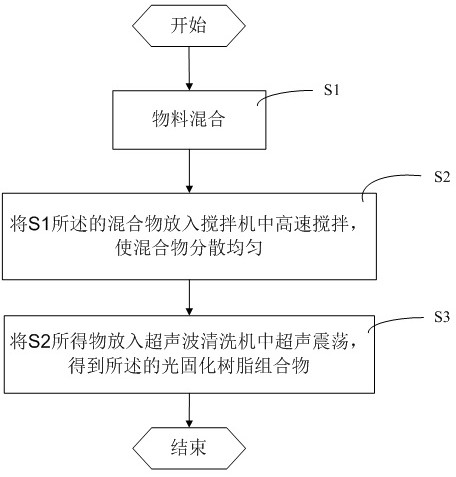

[0032] A preparation method of 3D printing resin for antibacterial wear-resistant shoes, comprising the following steps:

[0033] S1: 20-30 parts of carboxyl-terminated butadiene-modified acrylate, 10-30 parts of fluoroalkane-modified acrylate monomer, 10-15 parts of reactive diluent, 1-2 parts of polymerization inhibitor, light Mix 2~3 parts of initiator, 3~5 parts of pigment, 10~15 parts of filler and 0.5-2 parts of antibacterial finishing agent;

[0034] S2: Put the mixture described in S1 into a mixer and stir at high speed to make the mixture evenly dispersed;

[0035] S3: putting the product obtained in S2 into an ultrasonic cleaning machine for ultrasonic vibration to obtain the photocurable resin composition.

Embodiment 1

[0045] S1: 40 parts of carboxyl-terminated butadiene-modified polyester acrylate, 10 parts of fluoroalkane-modified acrylate monomer, 15 parts of reactive diluent TMPTA, 1 part of polymerization inhibitor p-phenol, photoinitiator 3 parts of TPO, 5 parts of pigment lithopone, 15 parts of filler silica, 1 part of antibacterial agent SCJ-963 and 10 parts of silane coupling agent;

[0046] S2: Put the mixture described in S1 into a mixer and stir at high speed to make the mixture evenly dispersed;

[0047] S3: putting the product obtained in S2 into an ultrasonic cleaning machine for ultrasonic vibration to obtain the photocurable resin composition.

Embodiment 2

[0049]S1: 35 parts of carboxyl-terminated butadiene-modified polyurethane acrylate, 15 parts of fluoroalkane-modified acrylate monomer, 15 parts of reactive diluent TMPTA, 2 parts of polymerization inhibitor p-benzoquinone, photoinitiator TPO 3 parts, pigment lithopone 5 parts, filler calcium carbonate 15 parts, antibacterial agent SCJ-963 2 parts and silane coupling agent 8 parts;

[0050] S2: Put the mixture described in S1 into a mixer and stir at high speed to make the mixture evenly dispersed;

[0051] S3: putting the product obtained in S2 into an ultrasonic cleaning machine for ultrasonic vibration to obtain the photocurable resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com