Color intrigue shell and preparation process thereof

A preparation process and magic color technology, which is applied in the field of magic color casing and its preparation process, can solve the problems of increasing the production cost of the mobile phone back cover, unfavorable lightening of the mobile phone back cover, increasing the thickness of the mobile phone back cover, etc., and achieving bright colors The effect of stability, simple structure, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

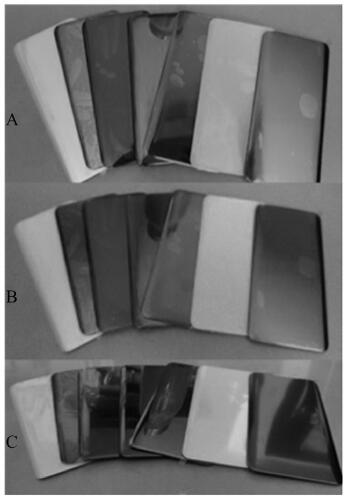

[0078] Example 1: Symphony mobile phone back cover

[0079] Prepare the alignment coating solution and the liquid crystal coating solution according to the following formulas:

[0080] Alignment coating liquid formula: 15% polyvinyl alcohol, 80% methanol and water, 5% fluorine-containing surfactant.

[0081] Liquid crystal coating solution formula: monomers satisfying formula (2) (where m and n are 4, R 1 is hydrogen atoms) 10%, monomers satisfying the formula (3) (the R 2 is methyl) 8%, CN 3%, 2,2'-azobisisobutyronitrile 0.15%, tricresyl phosphate 1%, polydimethylsiloxane 1%, trimethylsilanol 1% and Toluene 76%.

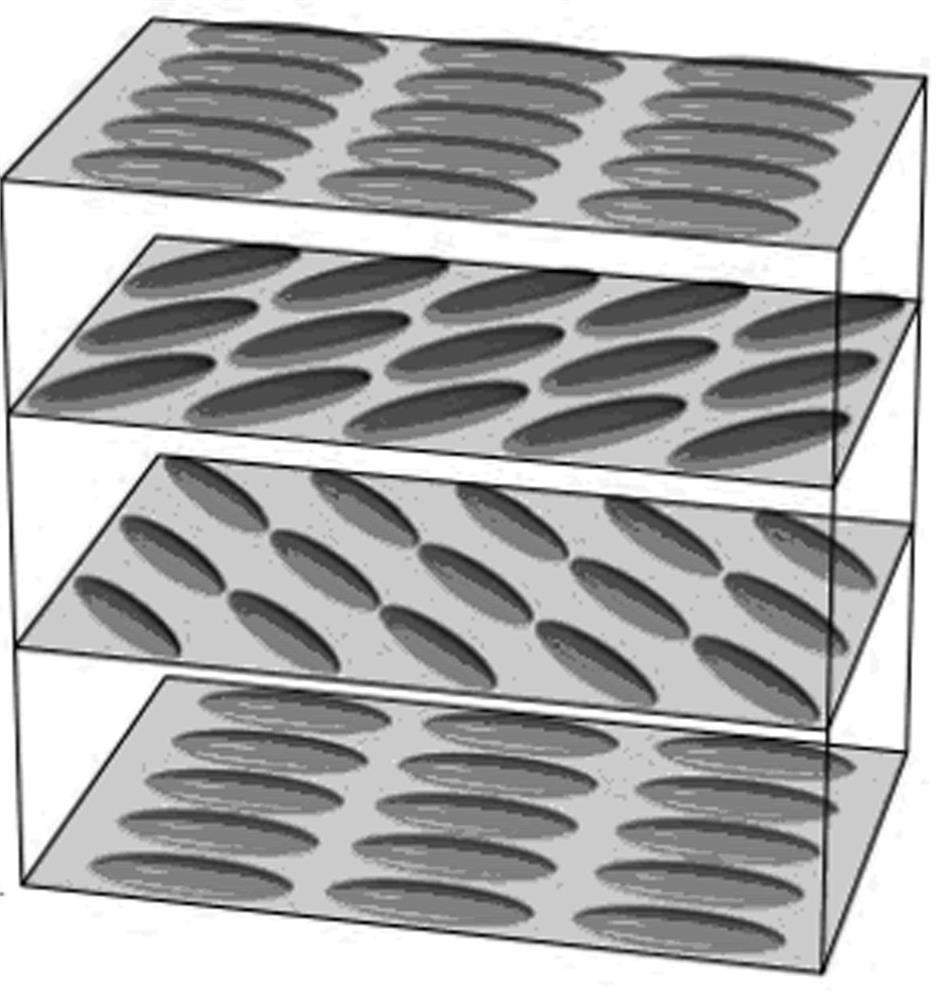

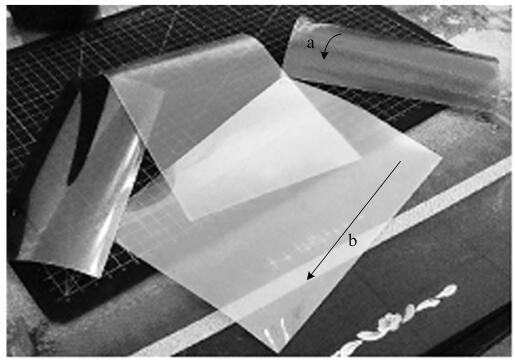

[0082] Coat the above-mentioned alignment coating solution on PET with a thickness of 100 μm by gravure coating method, send it to the hot air drying equipment after coating, and heat it at 80-85 ° C for 5 minutes to form a layer of alignment film on the PET film. The gauze rubbed and aligned the PET film to form an alignment layer, and obtained a release materi...

Embodiment 2

[0087] Example 2: Symphony mobile phone back cover

[0088] Prepare the alignment coating solution and the liquid crystal coating solution according to the following formulas:

[0089] Alignment coating liquid formula: polyvinyl alcohol 8%, methanol and water 85%, anionic surfactant 7%.

[0090] Liquid crystal coating solution formula: monomers satisfying formula (2) (where m and n are 6, R 1 is methoxy) 15%, monomers satisfying the formula (3) (the R 2 methyl) 20%, chiral agent satisfying formula (4) 2%, benzoin ether initiator 0.05%, tricresyl phosphate 0.05%, hydroxyl silicone oil 0.05%, trimethylsilanol 0.05% and toluene 62.8%.

[0091] Coat the above-mentioned alignment coating solution on PET with a thickness of 80 μm by gravure coating method, send it to the hot air drying equipment after coating, and heat it at 95-100 ° C for 8 minutes to form a layer of alignment film on the PET film. The gauze rubbed and aligned the PET film to form an alignment layer, and a rele...

Embodiment 3

[0092] Example 3: Symphony mobile phone back cover

[0093] Prepare the alignment coating solution and the liquid crystal coating solution according to the following formulas:

[0094] Alignment coating liquid formula: polyvinyl alcohol 10%, methanol and water 82%, fluorine-containing surfactant 8%.

[0095] Liquid crystal coating liquid formula: a monomer satisfying the formula (2) (where m is 4, n is 6, R 1 is methyl) 25%, monomers satisfying formula (3) (its R 2 phenyl) 5%, R1011 5%, benzoyl peroxide 1%, tricresyl phosphate 1%, 1,4-bis(hydroxydimethylsilyl)benzene 0.5% and ethyl acetate 62.5%.

[0096] Coat the above-mentioned alignment coating solution on PET with a thickness of 120 μm by gravure coating method, send it to the hot air drying equipment after coating, and heat it at 95-100 ° C for 3 minutes to form a layer of alignment film on the PET film. The gauze rubbed and aligned the PET film to form an alignment layer, and a release material was obtained. The perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com