Self-adaptive surface structure fine grinding device

A surface structure, self-adaptive technology, used in grinding drives, grinding/polishing safety devices, grinding machines, etc., can solve the problems of high price, complex design structure, time-consuming, etc., to reduce friction resistance, compact structure, avoid Effects of complex structures and loss of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

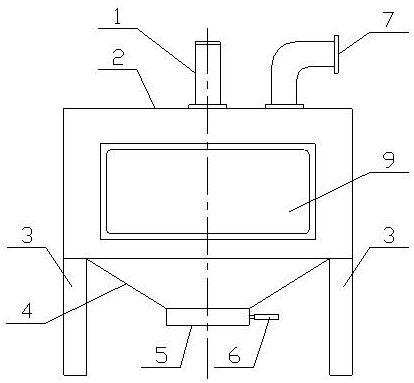

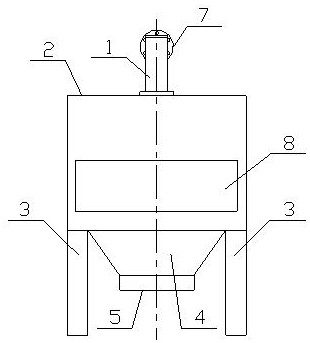

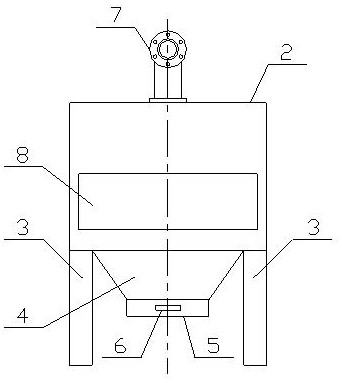

[0038] Such as Figure 1-6 , 9, the top of the polishing box body 2 is fixed with a cylinder assembly 1, a dust discharge pipe 7, the bottom has a support leg 3, a collection box 4, and the side wall has a feeding window 8 and an inspection window 9; one end of the dust discharge pipe 7 is connected to the polishing box The body 2 is connected, and the other end is connected with the ventilation and dust removal system. The collection box 4 is a funnel structure, and its lower end is connected with the discharge port 5, and a discharge valve 6 is arranged in the discharge port 5, and the discharge valve 6 can adjust the larger abrasive particles in the collection box 4 to be discharged from the discharge port 5; The cylinder body of the cylinder assembly 1 is fixed on the grinding box body 2, and its telescoping part is fixedly connected with the grinding support 11, and the grinding support 11 is a U-shaped structure.

[0039] The top of the hydraulic tank 16 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com