Intelligent numerical control machine tool tool changing frame

A technology of CNC machine tools and tool holders, which is applied in the direction of metal processing machinery parts, manufacturing tools, positioning devices, etc., and can solve problems such as damage to workpieces caused by knife collisions, damage to CNC machine tools, and chaotic tool sequences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

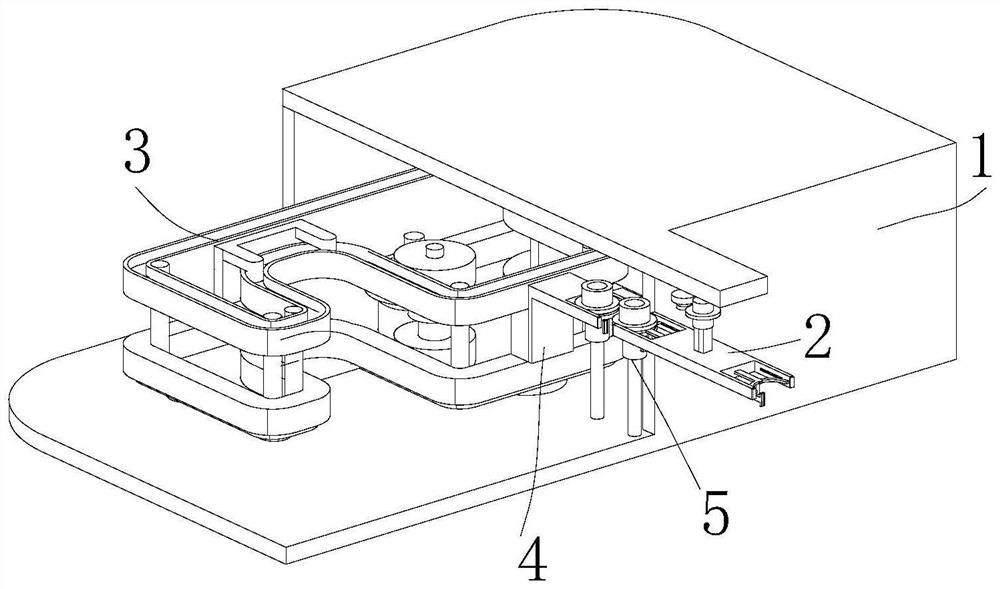

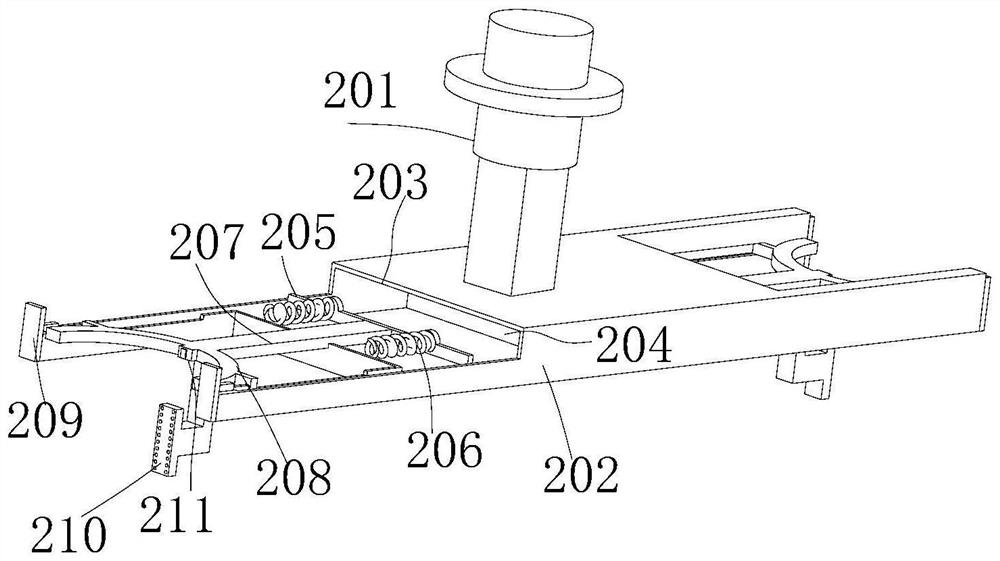

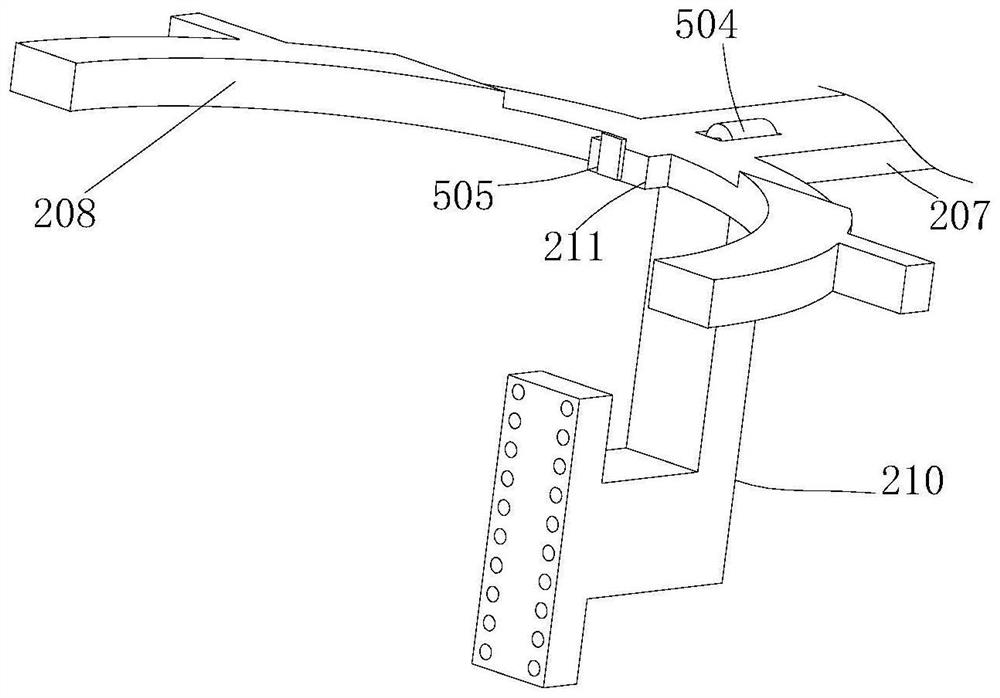

[0024] Embodiment one, such as Figure 1-6 As shown, it includes a tool magazine box 1, a tool changing mechanism 2 is fixedly installed on the inner top wall of the front end of the tool magazine box 1, a driving mechanism 3 is arranged inside the tool magazine box 1, and a knife pocket 4 is fixedly installed on the outer surface of the driving mechanism 3 , the middle part of the knife bag 4 is clamped with a knife handle 5, and the tool changing mechanism 2 includes a driving source 201, which can control the device to move up and down and rotate, and the driving source 201 is fixedly installed on the inner top wall of the front end of the tool magazine box 1. The bottom end of the source 201 is fixedly equipped with a tool changing sleeve 202 with the same two ends, and a groove 203 is opened inside the tool changing sleeve 202, and a fixed magnetic plate 204 is fixedly installed on the inner side wall of the groove 203, and the inside of the groove 203 is slidingly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com