Stud welding tool applied to pipeline electric field fingerprint corrosion detection technology

A technology for corrosion detection and electric field fingerprinting, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of accurate welding at the drawn mesh points, inaccurate welding points, affecting the accuracy of detection data, etc. Installation speed and efficiency, the same solder joint burning area, and the effect of standardizing the probe installation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

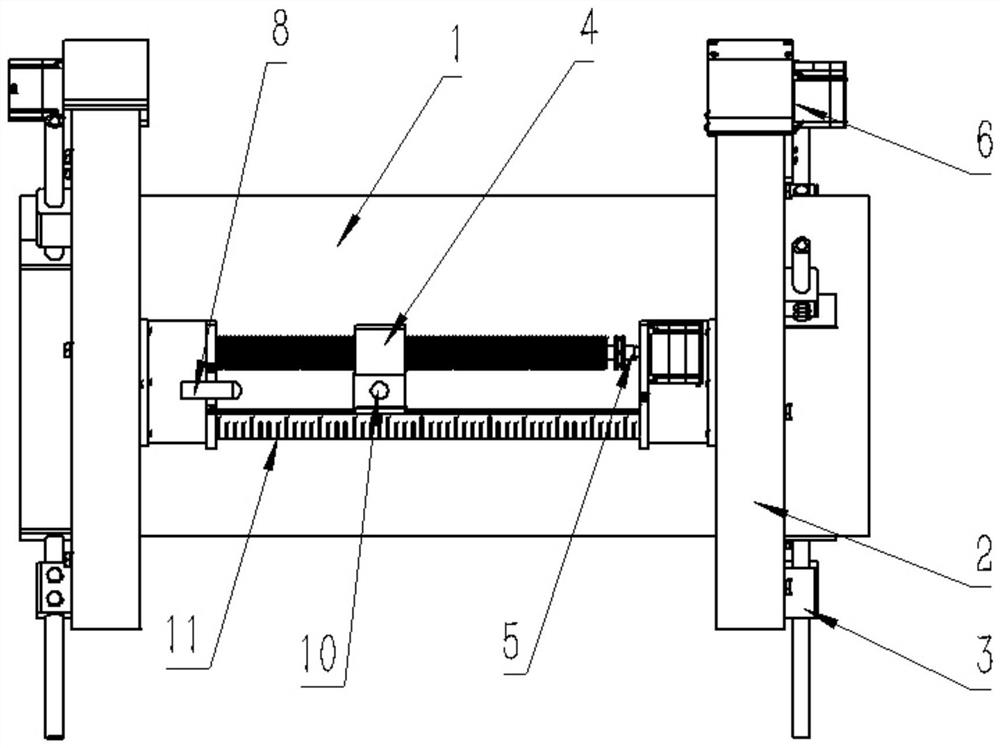

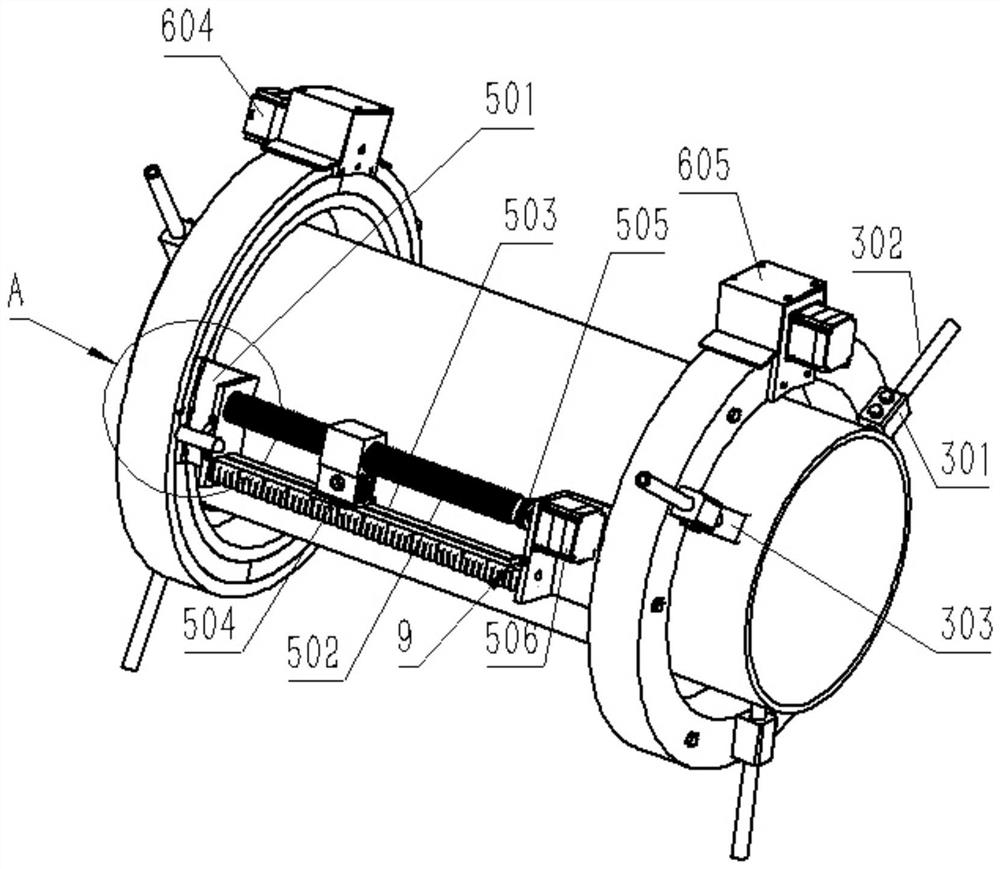

[0042] see Figure 1 to Figure 6 As shown, the present invention is a stud welding tool applied to the pipeline electric field fingerprint method corrosion detection technology, including two correspondingly arranged collars 2 that are sleeved on the outside of the pipeline 1 at the same time, and the outer wall of each collar 2 is fixedly connected with a A plurality of clamping parts 3 matched with the pipeline 1, a sliding block 4 is arranged between the two collars 2, and a stud welding torch station is arranged on the sliding block 4,

[0043] The sliding block 4 is connected with a translation mechanism 5 , and the translation mechanism 5 is connected with a rotation mechanism 6 .

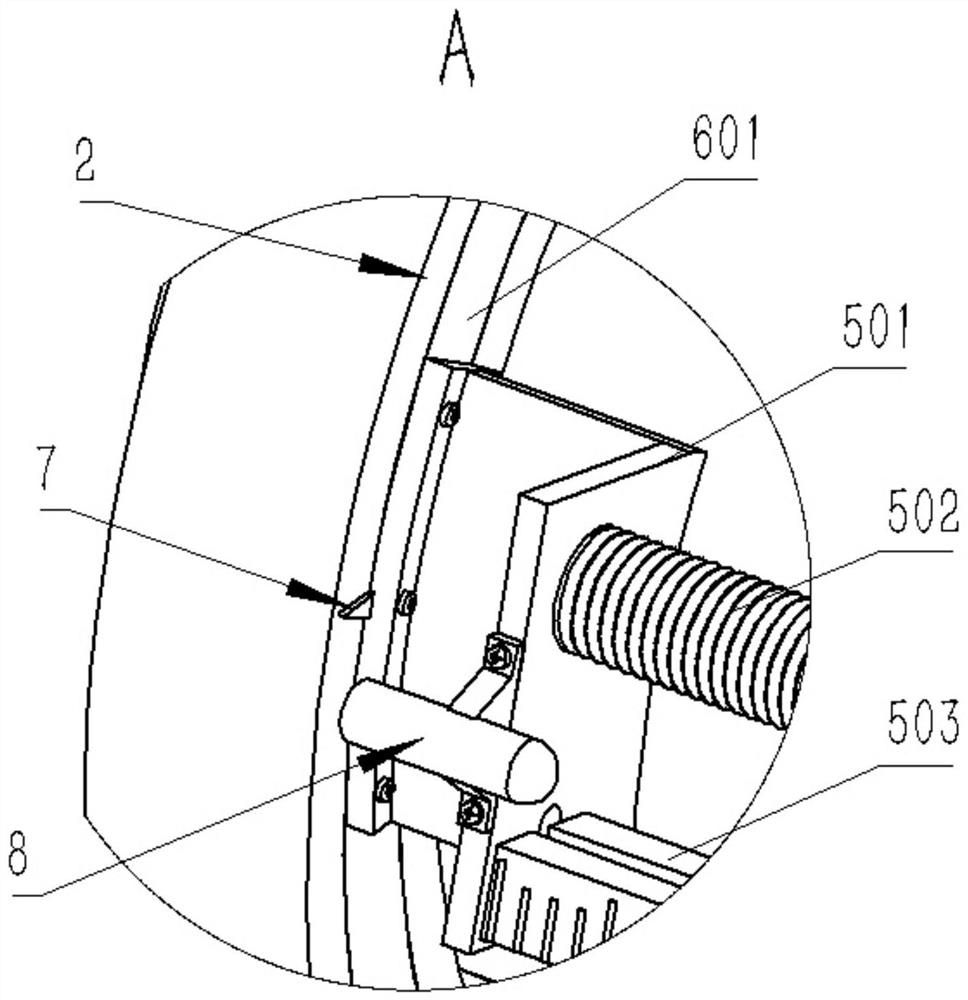

[0044] Each collar 2 is a hollow structure, and the rotating mechanism 6 includes swivels 601 respectively arranged in the two collars 2. The central rotating shaft of the corresponding collar 2 is coaxial, and several rubber wheels 602 are evenly arranged inside each swivel 601, and the rub...

Embodiment 2

[0049] On the basis of embodiment 1, the scale 11 parallel to the track 504 is pasted on the outer surface of the track 504, and a positioning pointer is arranged below the center of the positioning hole 10. The tip of the positioning pointer cooperates with the scale 11 to indicate that the positioning hole 10 is on the axis. direction of movement. The axial moving distance of the positioning hole 10 is no longer judged according to the pitch of the screw rod 502, and the axial positioning is faster and more accurate.

Embodiment 3

[0051] see Figure 7 , on the basis of the above-mentioned embodiment, the other is the same as the above-mentioned embodiment, and the difference from the above-mentioned embodiment is: the outer edge of the bottom of the sliding block 4 is fixedly connected to the support plate 508 through several connecting columns 507, and the bottom of the support plate 508 is fixedly connected and supported Plates 508 are perpendicular to the sliding plate 504, and the bottom surface of the support plate 508 is close to the top surface of the track 503;

[0052] The top surface of the support plate 508 and the bottom surface of the sliding block 4 are symmetrically provided with some pairs of draw-in grooves 509 that are all parallel to the guide rail 503 and mutually parallel to each other from the outside. Positioning holes 10 are provided on the 510, and the diameters of the positioning holes 10 provided on each positioning plate 510 are different.

[0053] When using stud welding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com