A chair stool automatic welding bracket

An automatic welding and chair stool technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as incorrect angle between iron rods, uneven iron rods, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

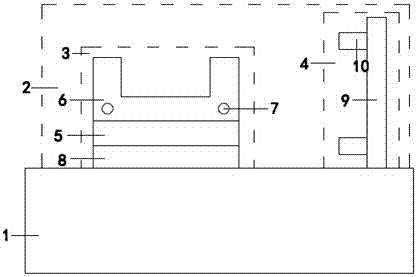

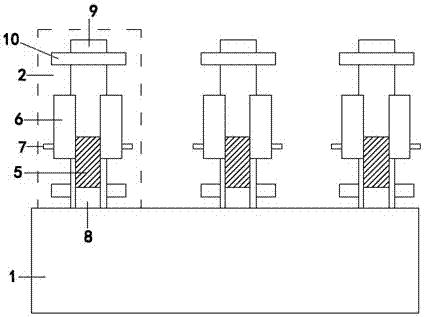

[0013] Such as Figure 1 to Figure 3 The shown automatic welding bracket for a chair and stool includes a base 1 and three fixing frames 2 .

[0014] Each fixing bracket 2 includes a first clip 3 and a second clip 4 .

[0015] The first clip 3 includes a fixed plate 5 , two fixed pieces 6 , two telescopic rods 7 , and a telescopic block 8 .

[0016] The second clip 4 includes a fixed block 9 and two limiter fingers 10 .

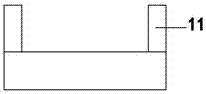

[0017] The fixed frame 2 is located above the base 1; the telescopic stick 7 runs through the fixed plate 5, and the two ends of the telescopic stick 7 are connected to the fixed piece 6; the telescopic block 8 is located on the fixed plate 5 below. The two limiter fingers 10 are arranged in the vertical direction on the side of the fixed block 9 close to the first clip 3; the horizontal cross section of the limiter fingers 10 is "concave". ” font, and the limiter means 10 includes 2 limit blocks 11. The limiter finger 10 is adjustable, and the distance ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap