Steel pipe internal rust removing equipment based on construction site

A technology for construction sites and steel pipes, applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of difficult removal of rust and poor cleaning effect, achieve strong use flexibility, solve the problem of cleaning the inside of steel pipes Rust, to ensure the normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

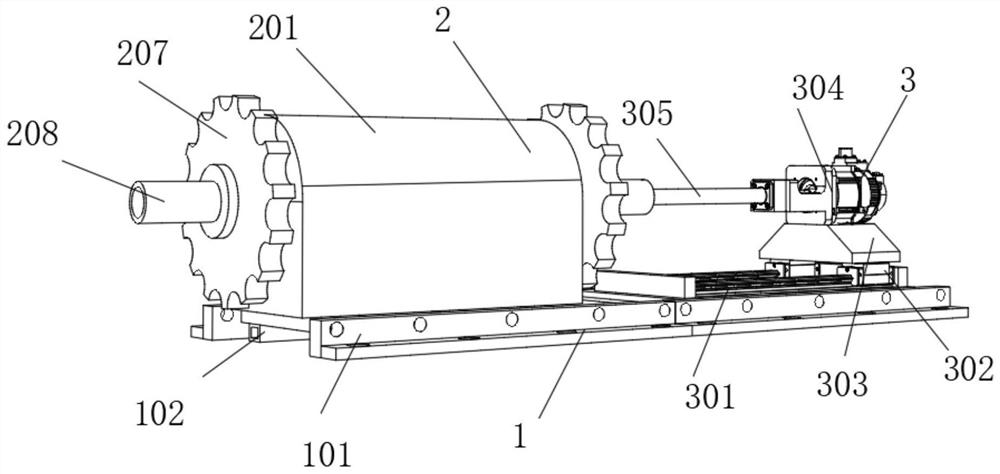

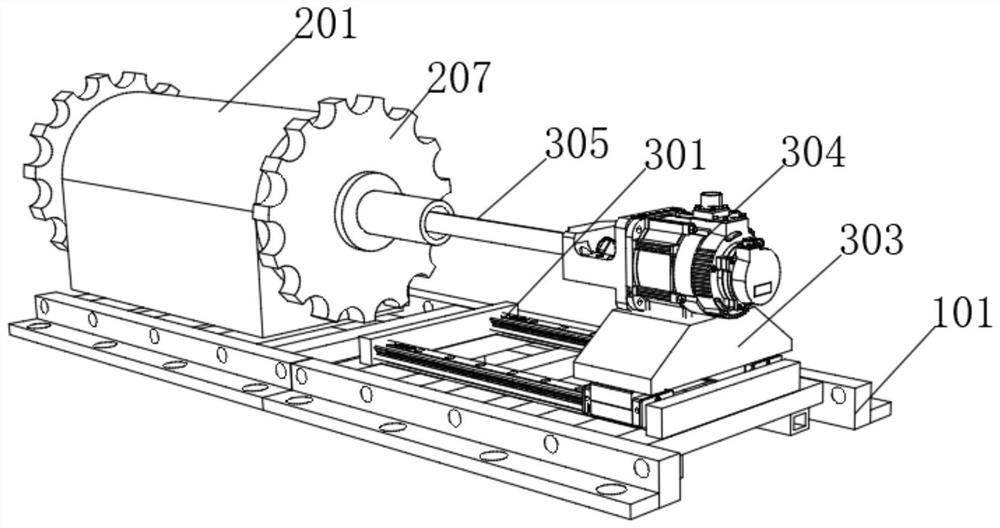

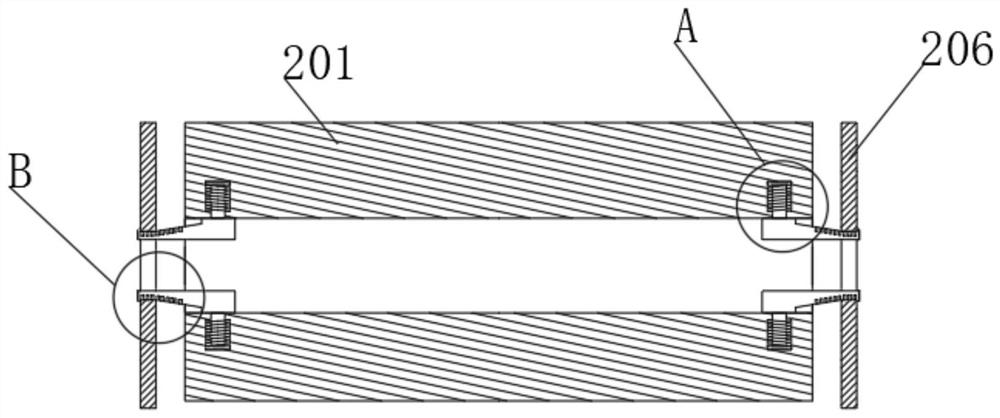

[0028] Such as Figure 1-7 As shown, the embodiment of the present invention provides a kind of internal rust removal equipment based on steel pipes for construction sites, including a support assembly 1, a fixing assembly 2, a driving assembly 3 and a cleaning assembly 4, the fixing assembly 2 is connected to the support assembly 1, and the driving assembly 3 is connected to the The support assembly 1 is connected, the cleaning assembly 4 is connected with the driving assembly 3, the fixed assembly 2 includes a fixed box 201 and two rotating disks 207, and the inner walls of the through holes on both sides of the fixed box 201 are provided with four limit grooves 202. The inside of the groove 202 is slidingly connected to the limiting plate 203, and the lower end of the limiting plate 203 is fixedly connected with a movable column 204, and the lower end of the movable column 204 penetrates the limiting groove 202 and extends to the inner through hole of the fixed box 201. Blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com