Continuous reactor for synthesizing high-crystallinity nanoscale solid electrolyte precursor and synthesis method

A solid-state electrolyte and high crystallinity technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, electrochemical generators, etc., can solve batches that are not suitable for industrial mass production and hydrothermal reduction methods The problem of small amount and large particle size of the material can be solved, and the particle size of the product is fine and uniform, the synthesis method is time-saving, and the effect of high energy density is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

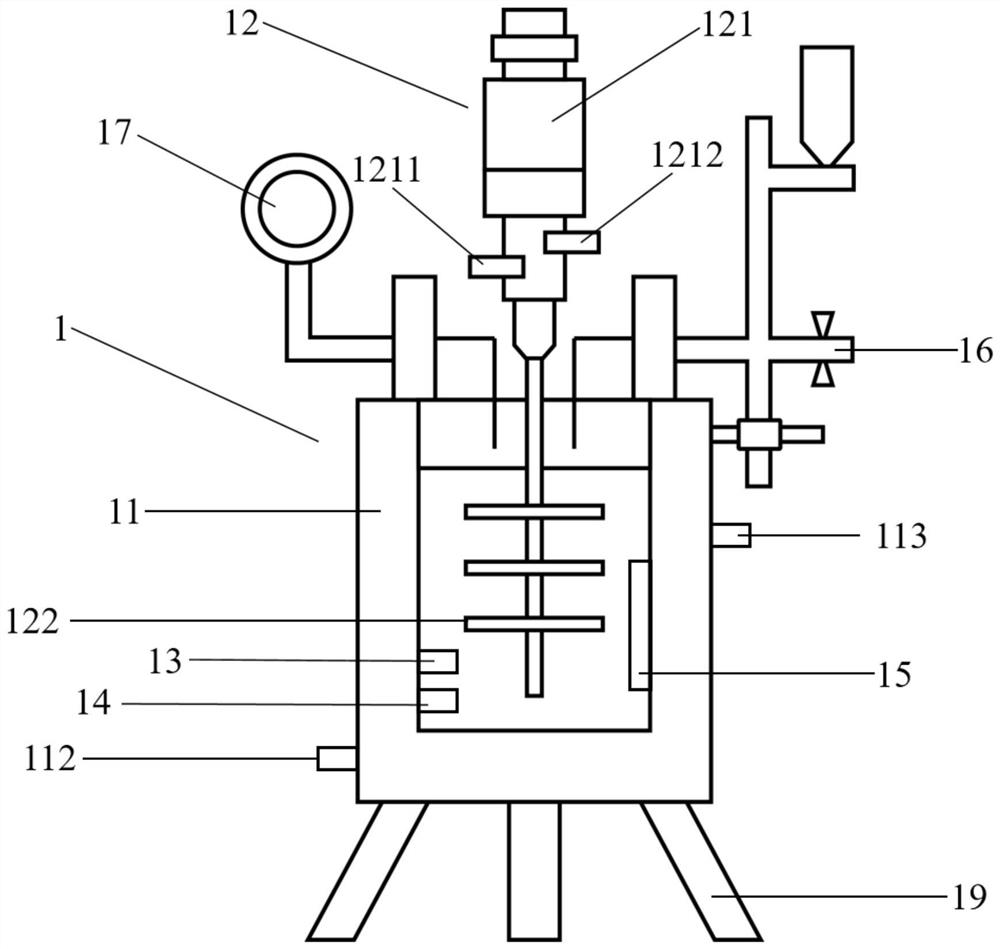

[0049] refer to figure 1 , this embodiment provides a continuous reactor for synthesizing a highly crystalline nanoscale solid electrolyte precursor, the continuous reactor 1 includes a reactor body 11;

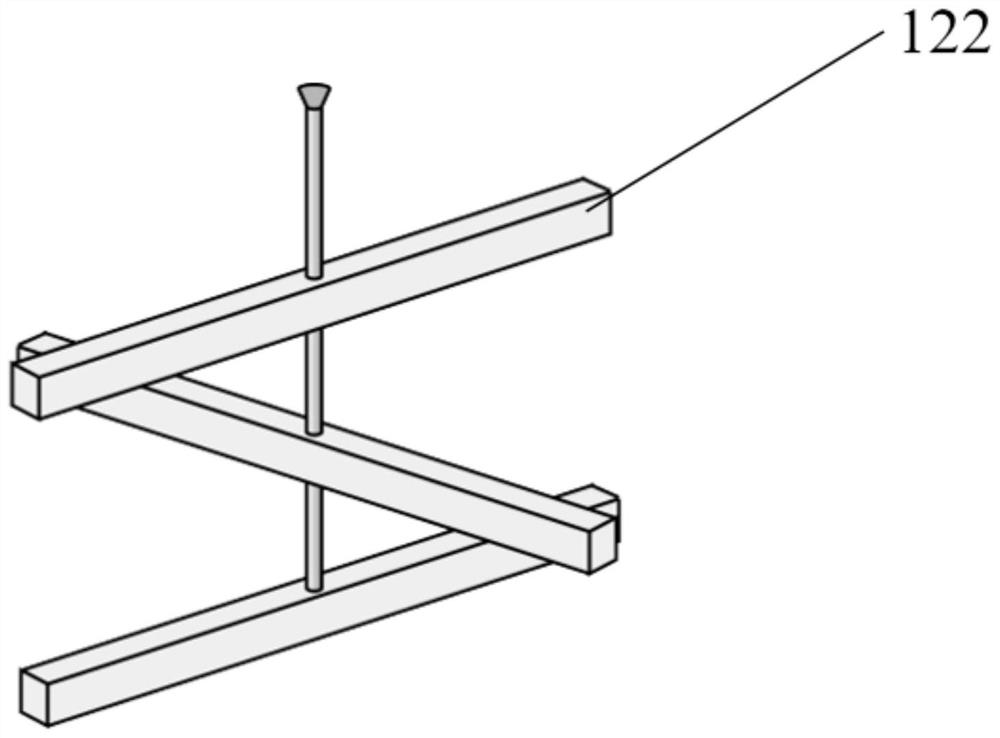

[0050] The reactor body 11 is provided with a stirring device 12, a heating device 15 and a charging controller 16; wherein,

[0051] The stirring device 12 is used to stir the reaction materials;

[0052] The heating device 15 is used to change the temperature in the reaction process;

[0053] The feed controller 16 is used to add reaction materials;

[0054] The reaction kettle body 11 also includes a temperature sensor 13 and a pH sensor 14, wherein,

[0055] The temperature sensor 13 is arranged inside the reactor body 11 and is electrically connected to the heating device 15 for detecting the reaction temperature and controlling the opening and closing of the heating device 15;

[0056] The pH sensor 14 is arranged inside the reactor body 11 and is electrically conne...

Embodiment 2

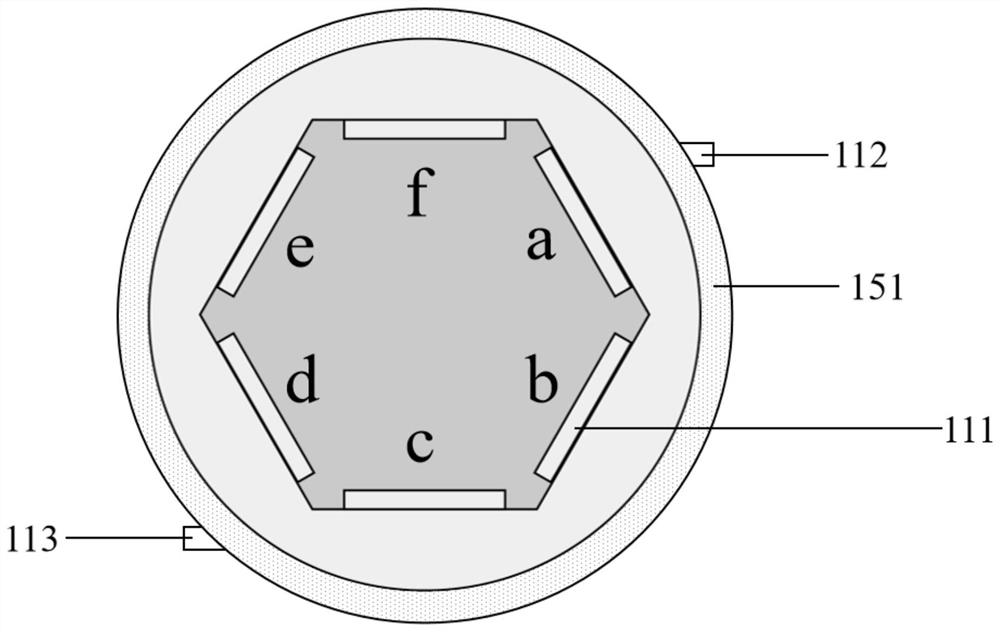

[0058] On the basis of Example 1, as an optional implementation, refer to figure 2 , the outside of the reaction kettle body 11 is wrapped with a cooling liquid interlayer 111, and the cooling liquid interlayer 111 can be filled with cooling liquid; the cooling liquid interlayer 111 is communicated with a cooling inlet 112 and a cooling outlet 113, and the cooling inlet 112 is located in the The cooling liquid interlayer 111 is at the bottom, and the cooling outlet 113 is located at the top of the cooling liquid interlayer 111 . In actual operation, the size of the reactor body 11 will change with different reaction requirements. When the reaction kettle body 11 is relatively large and the reaction temperature is too high and needs to be cooled quickly, the effect of only turning off the heating device is limited. Therefore, a cooling liquid interlayer 111, a cooling inlet 112, and a cooling outlet 113 are arranged outside the reactor body 11, and the effect of rapid cooling...

Embodiment 3

[0068] This embodiment provides a kind of synthetic method of highly crystalline nanoscale solid-state electrolyte precursor, and target product is Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP), including the following steps:

[0069] (S1) Solvent preheating: water and ethylene glycol are mixed according to the weight ratio of 2:1 and used as a solvent, put into the reactor body 11, the stirring device 12 is turned on and preheated to a temperature of 55° C. to obtain a mixture a;

[0070] (S2) dissolving the dispersant: adding polyvinylpyrrolidone to the mixture a, the amount of the polyvinylpyrrolidone added is 0.3% of the weight of the solvent, and stirring evenly to obtain the mixture b;

[0071] (S3)AO 6 Octahedral pre-nucleation: Ti(OC 4 h 9 ) 4 , Al(NO 3 ) 9H 2 O, the Ti 4+ Concentration is 18000ppm, the Al(NO 3 )·9H 2 O and the Ti(OC 4 h 9 ) 4 The molar ratio is 0.4. At this time, use low-speed stirring and turn on the microwave generator. The method is: the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com