Feeding device and feeding method applied to plate bending machine

A technology of bending machine and sheet metal, applied in the field of sheet metal processing, can solve the problems of low safety, slow bending processing speed, complicated manual feeding, etc., and achieve the effect of ensuring operation safety and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

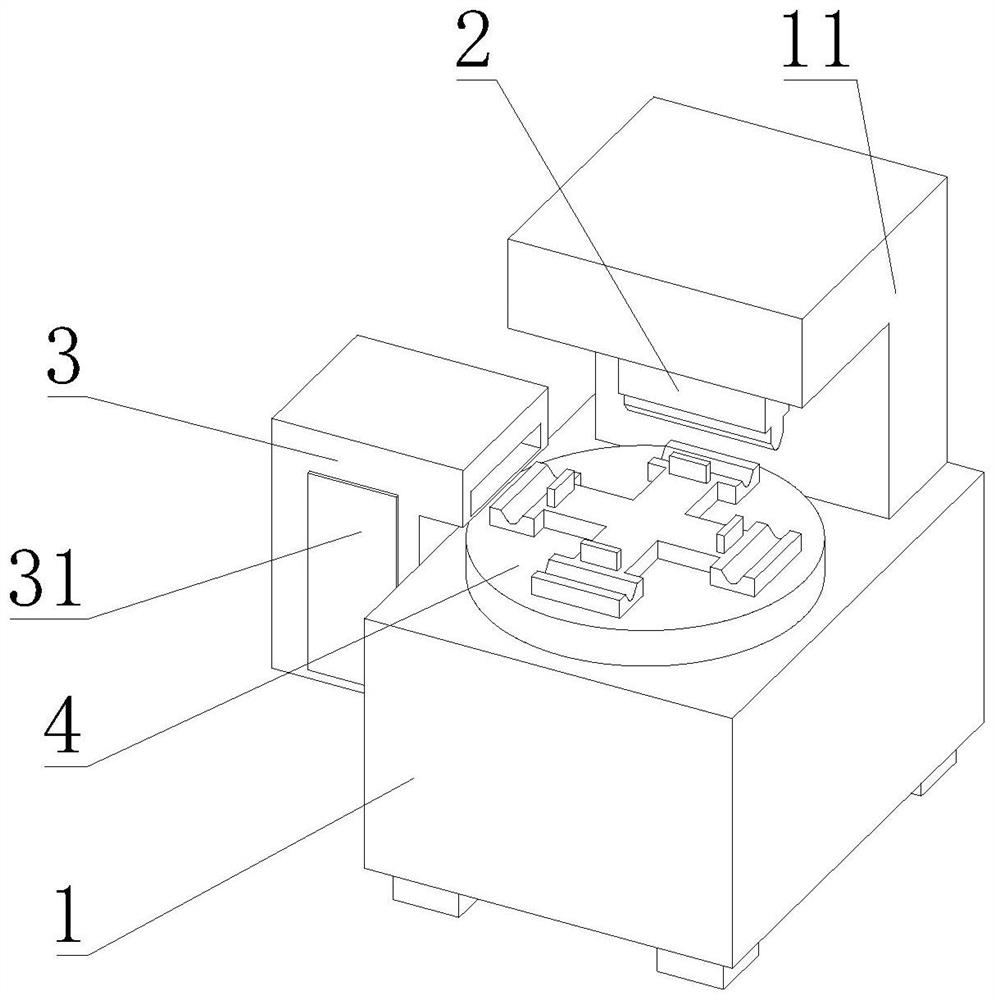

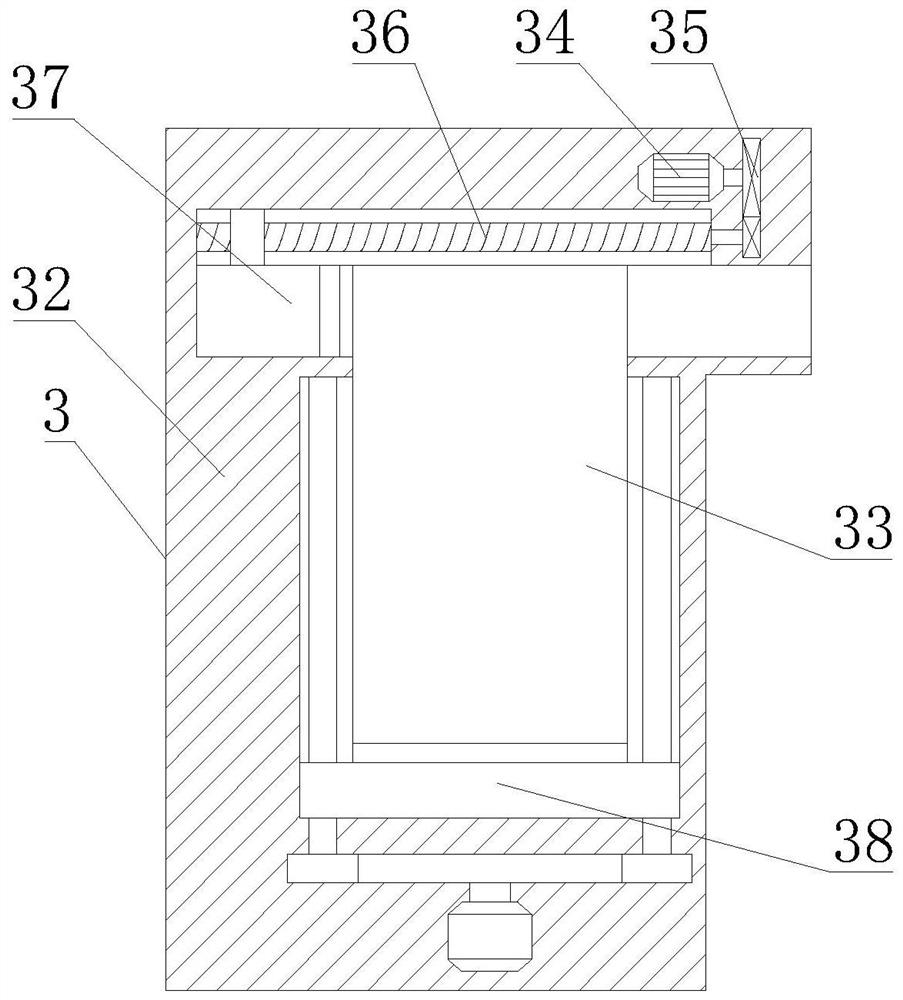

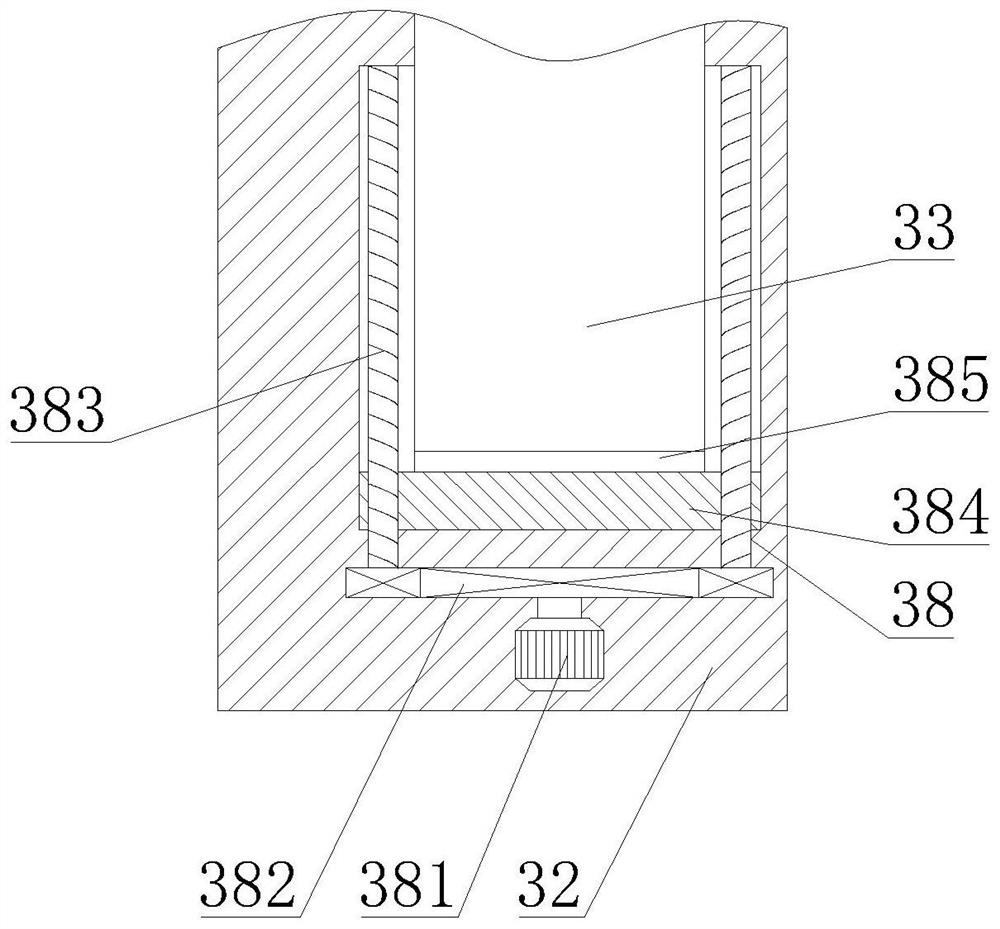

[0049] First aspect, such as figure 1 As shown in -7, the present invention provides a feeding device and a feeding method applied to sheet metal bending machines, including a bending machine 1, a support frame 11 is fixedly connected to the top and rear end of the bending machine 1, and the support frame The top of 11 is provided with a bending punch 2, the side of the bending machine 1 is fixedly connected with a feeding mechanism 3, the front end of the feeding mechanism 3 is movably connected with a box door 31, the top of the bending machine 1 is provided with a circulation mechanism 4, and the feeding mechanism 3. It includes a feeding box 32, which is fixedly connected to the side of the bending machine 1. The inside of the feeding box 32 is provided with a silo 33, and the inner top of the box door 31 is fixedly connected to a first motor 34. The output shaft of the first motor 34 Fixedly connected with a gear set 1 35, the left side of the bottom end of the gear set 1...

Embodiment 2

[0052] Such as figure 1 As shown in -7, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the circulation mechanism 4 includes a third motor 41, and the third motor 41 is fixedly connected inside the bending machine 1, and the third motor The output shaft of 41 is fixedly connected with driving wheel 42, the side of driving wheel 42 is meshed with driven wheel 43, the top of driven wheel 43 is fixedly connected with rotating disc 44, and the top of rotating disc 44 is fixedly connected with bending die 45, bending The top of mold 45 is provided with fixed distance mechanism 46, and fixed distance mechanism 46 comprises the 4th motor 461, and the 4th motor 461 is fixedly connected in the inside of rotating disk 44, and the output shaft of the 4th motor 461 is fixedly connected with bevel gear one 462, and The side meshing of gear one 462 is connected with bevel gear two 463, and the left side of bevel gear two 463 is fixedly connecte...

Embodiment 3

[0055] Such as figure 1 As shown in -7, on the basis of Embodiment 1, the present invention provides a feeding method applied to a sheet metal bending machine: the feeding method applied to a sheet metal bending machine includes the following steps:

[0056] Step 1: Open the box door 31, put the sheet into the feeding mechanism 3;

[0057] Step 2: Place the plate on the circulation mechanism 4 through the feeding mechanism 3;

[0058] Step 3: Determine the size of the sheet material to be bent through the distance-fixing mechanism 46;

[0059] Step 4: Rotate the circulation mechanism 4 to bend the sheet through the bending punch 2;

[0060] Step 5: Rotate the circulation mechanism 4 again, and take out the blank.

[0061] Step two also includes the following steps:

[0062] A1: Start the first motor 34 and drive the gear set 1 35 to rotate;

[0063] A2: The first screw rod 36 is driven to rotate by the rotation of the gear set one 35;

[0064] A3: Drive the push block 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com