Equipment for collecting and conveying VOCs loading gas and method for safely collecting and conveying VOCs gas

A gas and equipment technology, which is applied in the field of VOCs loading gas collection and transportation equipment, can solve the problems of patents and literature gaps, VOCs collection and processing hazards, etc., and achieve the effect of reducing VOCs emissions, efficient collection and transportation, and reducing the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

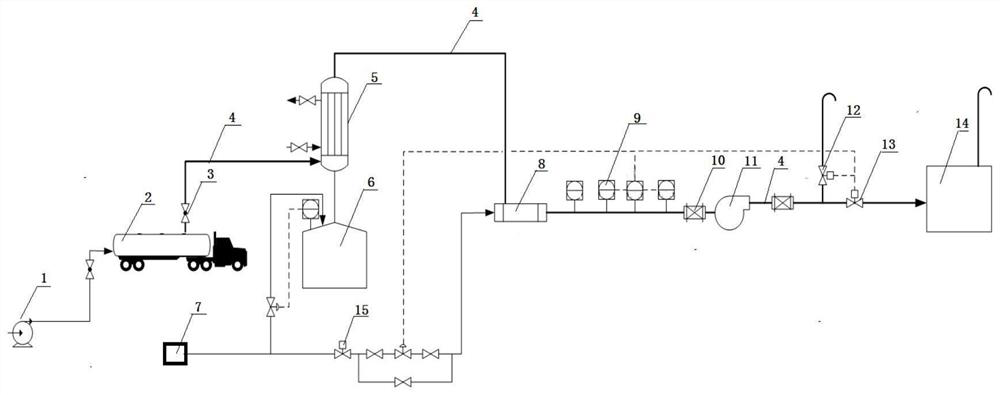

Embodiment 1

[0050] During the loading process of 3-chloropropene, connect the gas collection pipe to the exhaust port of the 3-chloropropene tank car, start the loading of 3-chloropropene, and at the same time turn on the fan of the gas collection pipe, the VOCs gas in the tank car , enter the 0°C chilled water condenser from the collection pipe at a flow rate of 3m / s, and part of the gas condenses into the nitrogen-sealed FRP collection tank. While turning on the fan, open the nitrogen gas valve and the gas vent valve, and the gas vent valve and the oxygen analyzer. The distance between the pipelines is 40 meters, the control pressure (gauge pressure) is 1.5KPa, and the flow rate of nitrogen gas is controlled. The uncondensed loading gas and nitrogen gas are mixed evenly in the mixer. It is detected by the three-choice oxygen analyzer, and the oxygen analyzer is in situ Laser oxygen analyzer. When the mixed gas reaches below 4% oxygen content, close the organic gas vent valve, open the o...

Embodiment 2

[0052] During the loading process of MTBE, connect the gas collection pipe to the exhaust port of the MTBE tank car, start the MTBE loading, and at the same time turn on the fan of the gas collection pipe, the VOCs gas in the tank car will flow from the collection pipe at a flow rate of 5m / s Enter the -5°C chilled water condenser (salt water condensation), and part of the gas condenses into the stainless steel collection tank. While turning on the fan, open the nitrogen gas valve and the gas vent valve. The pipe distance between the gas vent valve and the oxygen analyzer is 50 meters, control pressure (gauge pressure) 1.5KPa, control nitrogen flow rate, uncondensed loading gas and nitrogen are mixed evenly in the mixer, and are tested by three-selection oxygen analyzer, the oxygen analyzer is an in-situ laser oxygen analyzer. When the mixed gas reaches below 3% oxygen content, close the organic gas vent valve, open the organic gas delivery valve, so that the organic gas enters ...

Embodiment 3

[0054] During the gasoline loading process, connect the gas collection pipe to the exhaust port of the gasoline tank car, start the gasoline loading, and at the same time turn on the fan of the gas collection pipe, the VOCs gas in the tank car will flow from the collection pipe at a flow rate of 6m / s Enter the -5°C chilled water condenser (salt water condensation), and part of the gas condenses into the stainless steel collection tank. While turning on the fan, open the nitrogen gas valve and the gas vent valve. The pipe distance between the gas vent valve and the oxygen analyzer is 50 meters, control pressure (gauge pressure) 1.5KPa, control nitrogen flow rate, uncondensed loading gas and nitrogen are mixed evenly in the mixer, and are tested by three-selection oxygen analyzer, the oxygen analyzer is an in-situ laser oxygen analyzer. When the mixed gas reaches below 2% oxygen content, close the organic gas vent valve, open the organic gas delivery valve, so that the organic ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com