Feedback system of aluminum foil last-stage formation electrolysis power supply and feedback method thereof

An electrolytic power supply and feedback system technology, applied in general control systems, control/regulation systems, anodizing and other directions, can solve the problems of unstable detection data and large errors in detection data, and achieve simple structure, stable operation and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

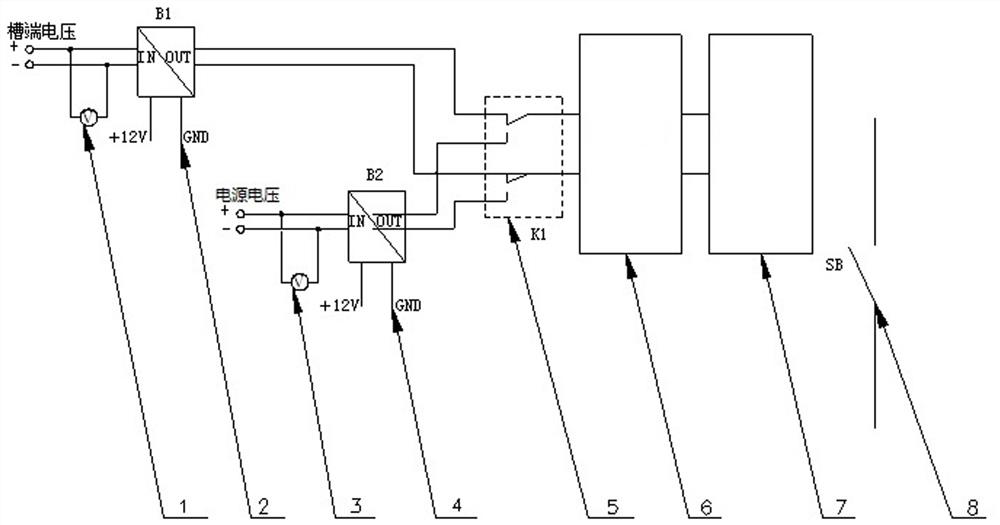

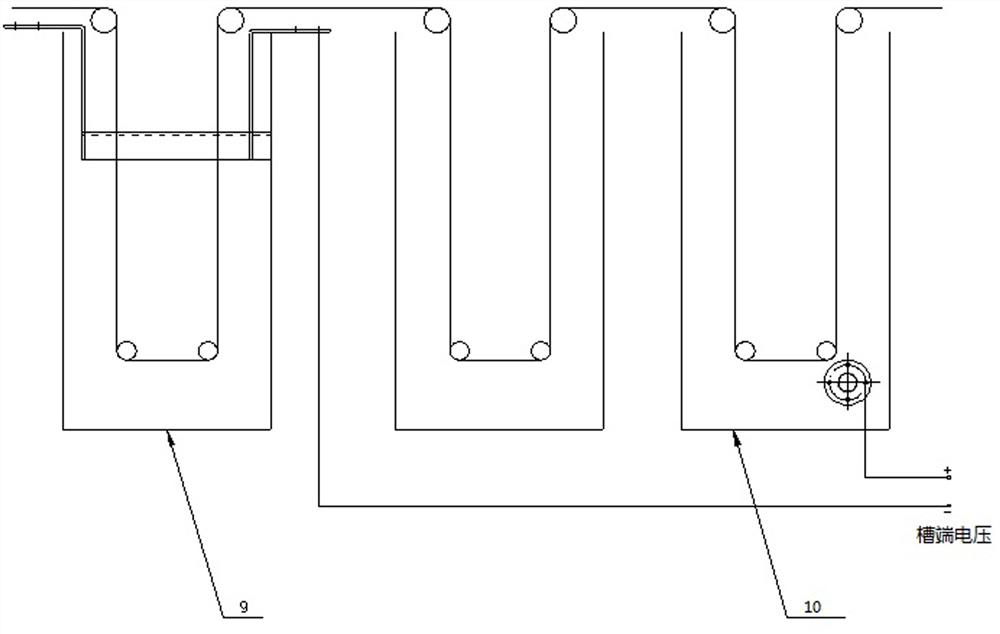

[0031] A feedback system for aluminum foil final-stage electrolytic power supply, including a tank terminal voltmeter 1, a tank terminal voltage and power isolation sensor 2, a machine terminal voltmeter 3, a machine terminal voltage and power isolation sensor 4, a relay 5, a circuit unit 6 and an adjustment unit 7 , transfer switch SB8, electrolytic tank A 9, electrolytic tank B 10;

[0032] Described tank terminal voltmeter 1 is connected in parallel with positive and negative poles of tank terminal voltage; described tank terminal voltage is the voltage of the electrolytic cell that needs to be fed back, that is, the pole plate of electrolytic cell A9 is the negative pole of tank terminal voltage; The stainless steel flange of the electrolytic cell B10 is the positive pole of the cell terminal voltage; the electrolytic cell B10 is a chemical conversion cell that does not require electrolytic treatment, but the conductivity of the solution is as high as 50ms / cm or more, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com