Optical camera lens

A camera lens, optical technology, applied in optics, optical components, instruments, etc., can solve the problem of autofocus and miniaturization being difficult to take into account at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

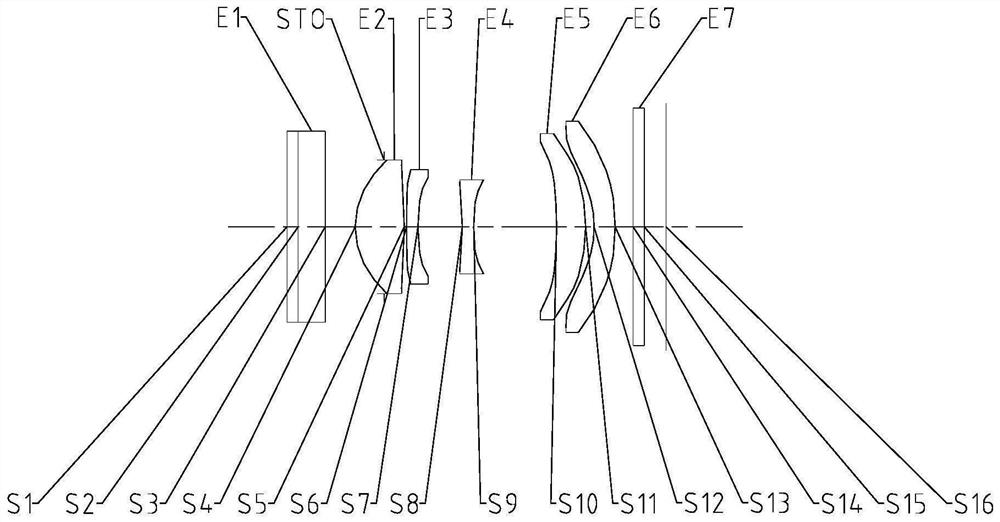

[0066] Such as Figure 1 to Figure 47 As shown, the optical camera lens includes a first lens with continuously variable refractive power, a second lens with positive refractive power, and a third lens with negative refractive power along the optical axis from the light incident side to the light output side. , a fourth lens with power, a fifth lens with power and a sixth lens with power; the first lens is a liquid lens; the surface of the second lens toward the exit side is a convex surface; the fifth lens The surface facing the incident side is a concave surface; wherein, the air gap T34 between the third lens and the fourth lens on the optical axis and the central thickness CT3 of the third lens on the optical axis satisfy: 3.5<T34 / CT3<5.0.

[0067] Preferably, 3.6

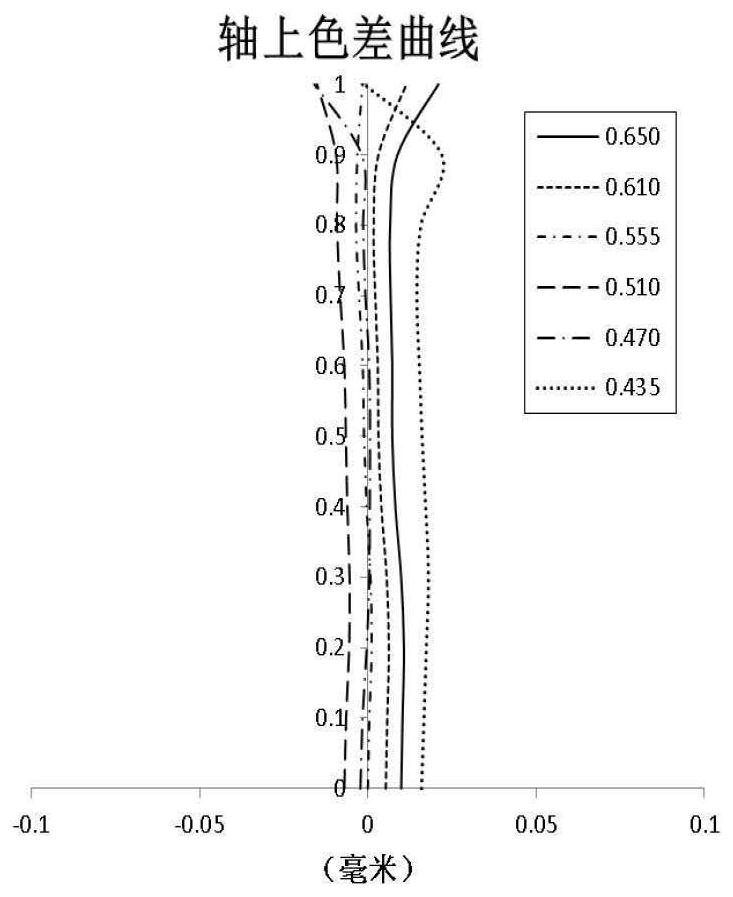

[0068] By effectively distributing the focal power and surface shape of each lens, it is conducive to the smooth transition of light, and at the same time, it is beneficial to improve the resoluti...

Embodiment 2

[0085] Such as Figure 1 to Figure 47 As shown, the optical camera lens includes a first lens with continuously variable refractive power, a second lens with positive refractive power, and a third lens with negative refractive power along the optical axis from the light incident side to the light output side. , a fourth lens with power, a fifth lens with power and a sixth lens with power; the first lens is a liquid lens; the surface of the second lens toward the exit side is a convex surface; the fifth lens The surface facing the incident side is a concave surface; wherein, the effective focal length f of the optical camera lens and the entrance pupil diameter EPD of the optical camera lens satisfy: 2.5<f / EPD<3.0.

[0086] Preferably, 2.5

[0087] By effectively distributing the focal power and surface shape of each lens, it is conducive to the smooth transition of light, and at the same time, it is beneficial to improve the resolution capability of the optical cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com