Coal reservoir structure testing while-drilling bit based on nuclear magnetic resonance and testing method

A technology of nuclear magnetic resonance and structural testing, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve problems that do not take into account the real-time influence of coal body structure, so as to improve data validity and credibility, and ensure The effect of safety and saving the initial cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

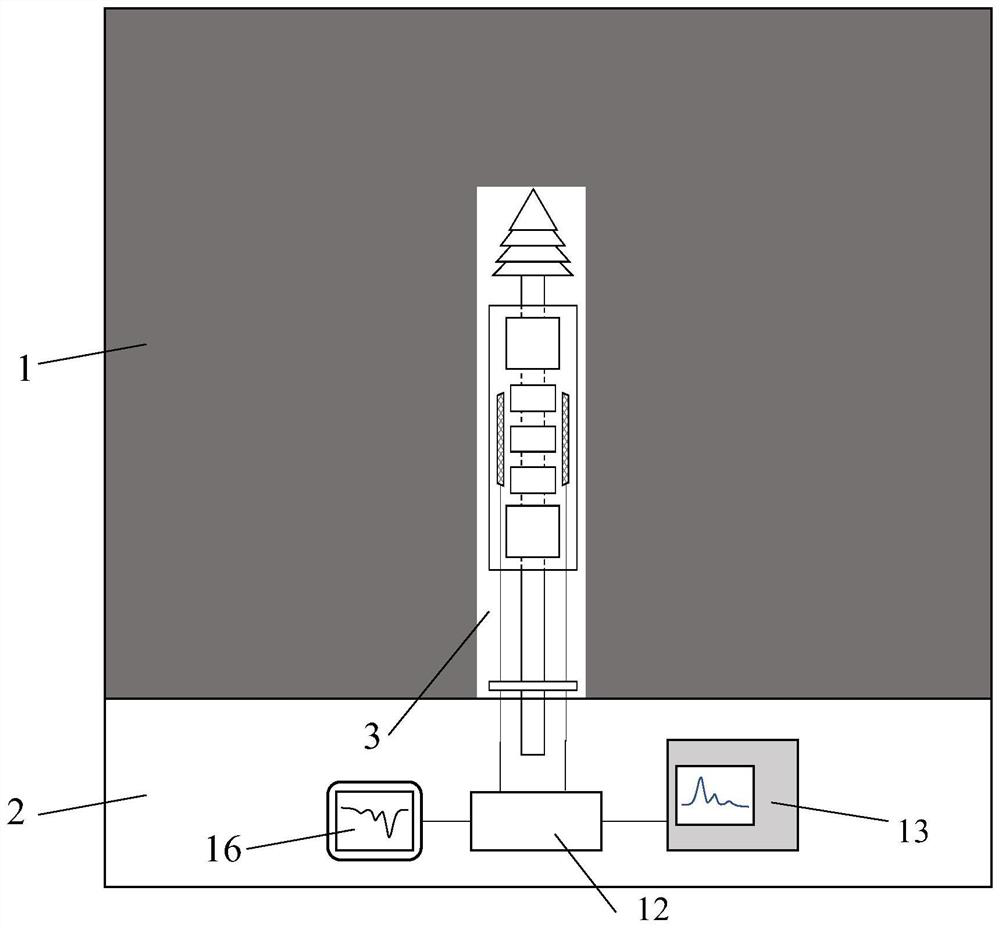

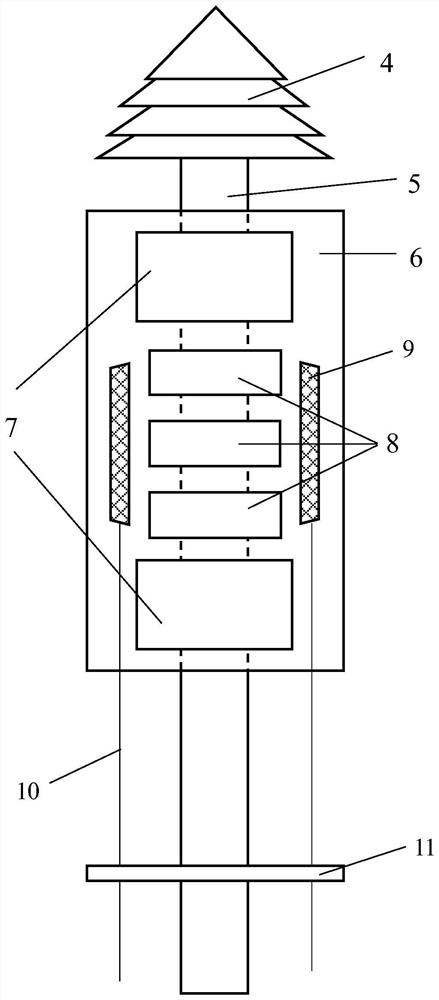

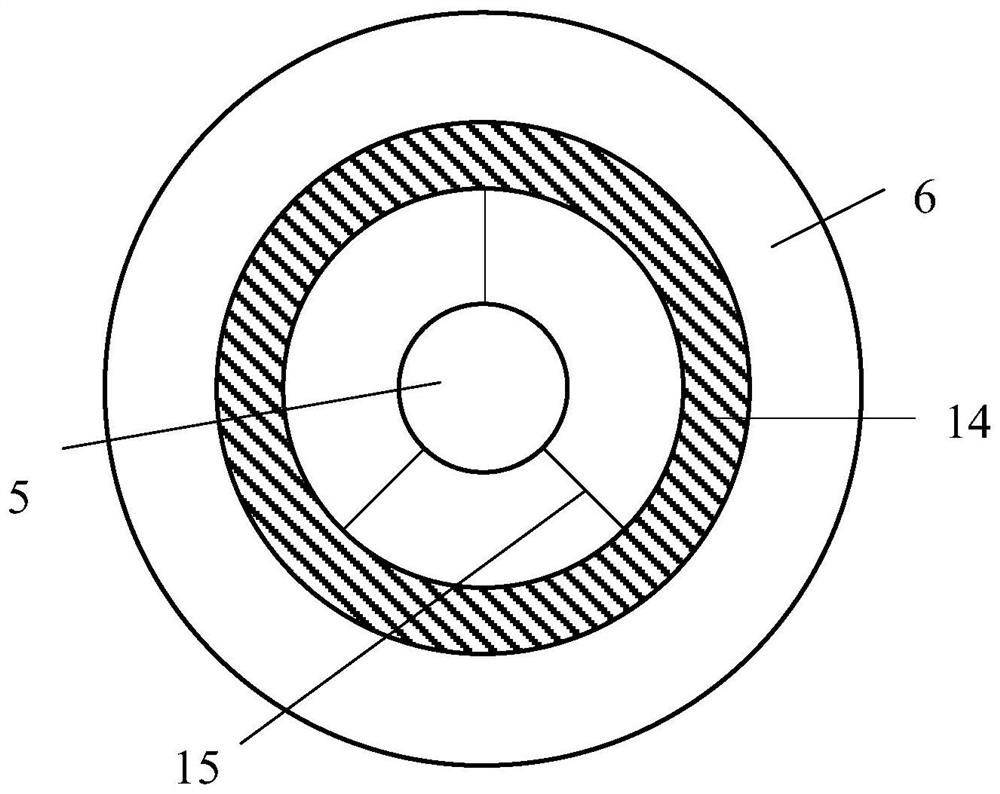

[0028] Such as figure 2 and 3 As shown, a coal reservoir structure testing probe while drilling based on nuclear magnetic resonance includes a drill bit 4, a drill pipe 5, a nuclear magnetic probe, an electromagnetic converter 12, a radio frequency generator and a signal processor 13, and the nuclear magnetic probe includes a probe housing 6, Antenna 9, annular main magnet 7 and annular secondary magnet 8, annular main magnet 7 is two, two annular main magnets 7 are coaxially arranged in the probe housing 6, and the magnetic conduction directions of the two annular main magnets 7 are along the respective In the axial direction, there are a plurality of annular secondary magnets 8, and a plurality of annular secondary magnets 8 are equidistantly arranged between two annular main magnets 7, and a plurality of annular secondary magnets 8 are on the same axis as the two annular main magnets 7; The magnetic conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com