High-concentration industrial wastewater catalytic oxidation treatment equipment and treatment method

A technology for catalytic oxidation of industrial wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that catalytic oxidation treatment equipment is difficult to meet technical requirements, high-concentration industrial wastewater treatment Poor effect, unreasonable setting of treatment tank structure, etc., to achieve the effect of improving catalytic oxidation effect, photocatalytic effect, and agitation and mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

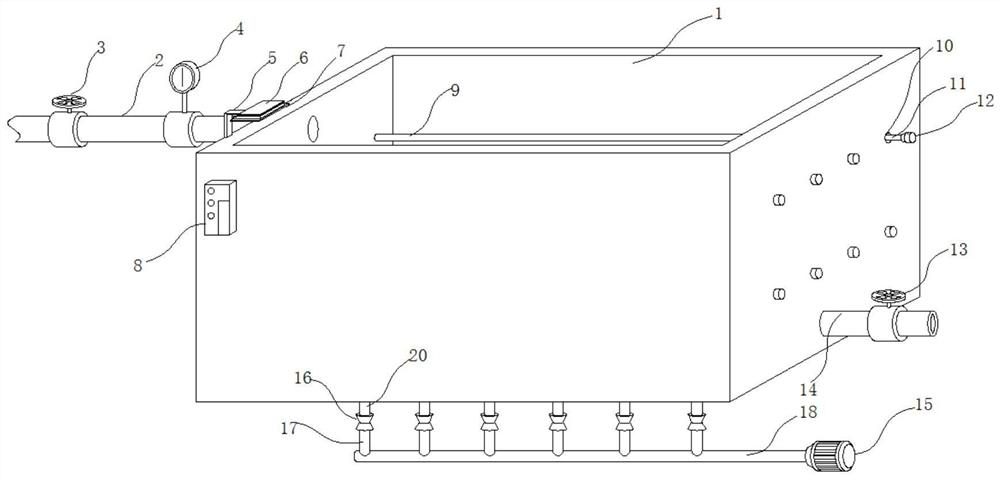

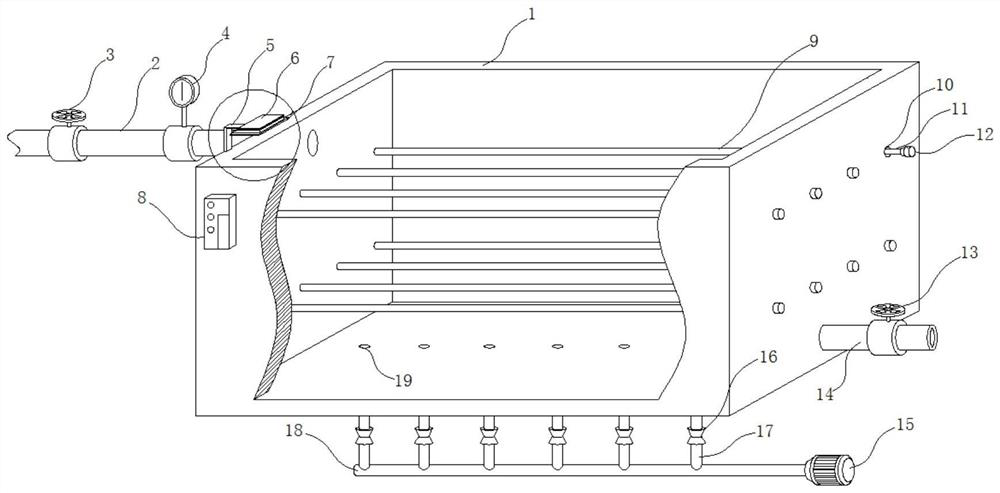

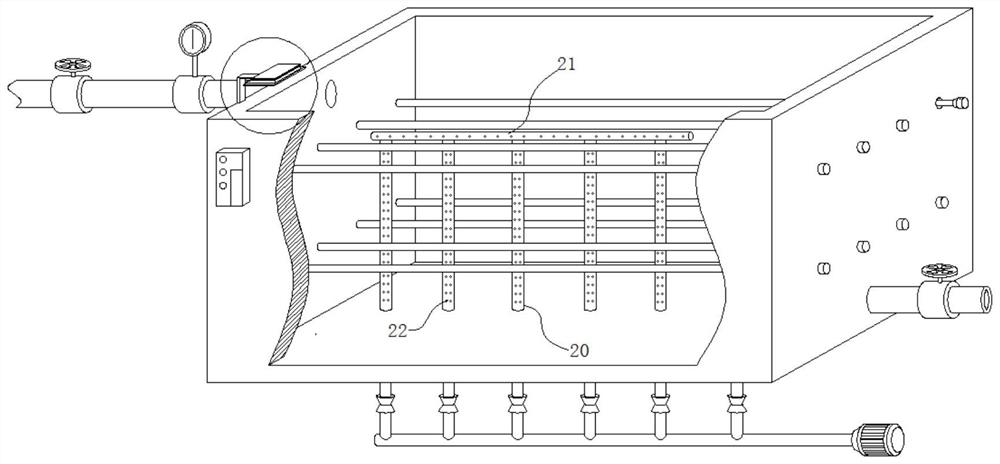

[0030] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made.

[0031] Such as figure 1 with figure 2 As shown, in this embodiment, the high-concentration industrial wastewater catalytic oxidation treatment equipment includes a treatment pool 1, the left end of the treatment pool 1 is provided with a water inlet assembly, and the right end of the treatment pool 1 is provided with a drainage assembly. 1. An aeration assembly is provided at the bottom, and a metering assembly is provided at the connection between the water inlet assembly and the treatment tank 1. A controller 8 is provided on the outer wall of the treatment tank 1; The water inlet assembly is provided with several transparent cover pipes 9 towards the direction of the drainage assembly, at least one end of the transparent cover pipe 9 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com