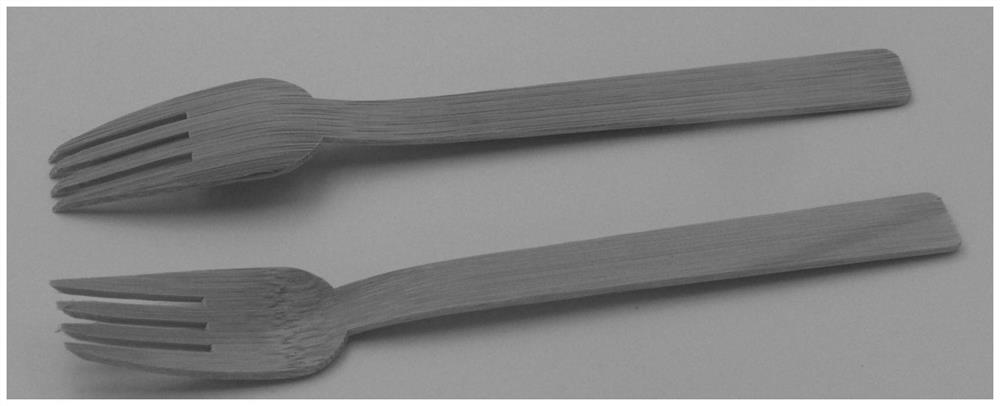

A kind of preparation method of bamboo slice homogenization bamboo tableware

A technology of homogenization and bamboo chips, which is applied in the field of bamboo processing, can solve problems such as cracking, achieve the effects of reducing specification differences, reducing deformation and damage rates, and reducing color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the bamboo slice homogenization bamboo tableware (bamboo spoon) of the present embodiment, the method is:

[0034] S1, bamboo strip end face scanning positioning and opening: split bamboo, remove green, remove yellow, be processed into a length that is 3cm in width, and be a specification rectangular bamboo strip with a thickness of 0.5cm, scan and position the end face of the described specification rectangular bamboo strip , taking the distribution of vascular bundles at the center of the width direction of the rectangular bamboo strip of the specification as the criterion, according to the vertical direction of the rectangular bamboo strip of the specification every 2 to 3 vascular bundles as the basis, and after drying, obtain water-containing vascular bundles. Bamboo chips with a rate of ≤10%;

[0035] Bamboo slices have basically complete vascular bundle organization, which ensures good strength of bamboo slices;

[0036] S2, surface spr...

Embodiment 2

[0042] The preparation method of the bamboo slice homogenization bamboo tableware (bamboo spoon) of the present embodiment, the method is:

[0043] S1, bamboo strip end surface scanning positioning and opening: the bamboo material is divided, removed green, and yellow is removed, and the length is that the width is 6cm, and the thickness is the specification rectangular bamboo strip of 1cm, and the end surface of the described specification rectangular bamboo strip is scanned and positioned, Taking the distribution of vascular bundles at the center of the width direction of the rectangular bamboo strips of the specification as the criterion, according to the direction perpendicular to the cross-section of the rectangular bamboo strips of the specification, the slices are split on the basis of every 3 vascular bundles, and after drying, the moisture content is less than or equal to 10. % bamboo chips; the bamboo chips have basically complete vascular bundle organization, which e...

Embodiment 3

[0050] The preparation method of the bamboo slice homogenization bamboo tableware (bamboo spoon) of the present embodiment, the method is:

[0051] Scanning, positioning and opening of the end surface of the bamboo strip: dividing the bamboo material, removing the green and yellowing, and processing it into a rectangular bamboo strip with a length of 4 cm and a thickness of 0.6 cm, and scanning and positioning the end surface of the rectangular bamboo strip of the specification to obtain a The distribution of vascular bundles at the center of the width direction of the rectangular bamboo strip of the specification shall prevail, and the slices shall be split according to every 3 vascular bundles in the vertical direction of the cross-section of the rectangular bamboo strip of the specification. After drying, the moisture content is less than or equal to 10%. of bamboo chips;

[0052] Bamboo slices have basically complete vascular bundle organization, which ensures good strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com