Device for heating material based on high-power laser

A high-power laser, heating material technology, used in quenching devices, laser welding equipment, heat treatment equipment and other directions, can solve the problems of inability to locate and fix the workpiece, no cooling mechanism, long cooling time, etc., to save manpower, improve efficiency, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

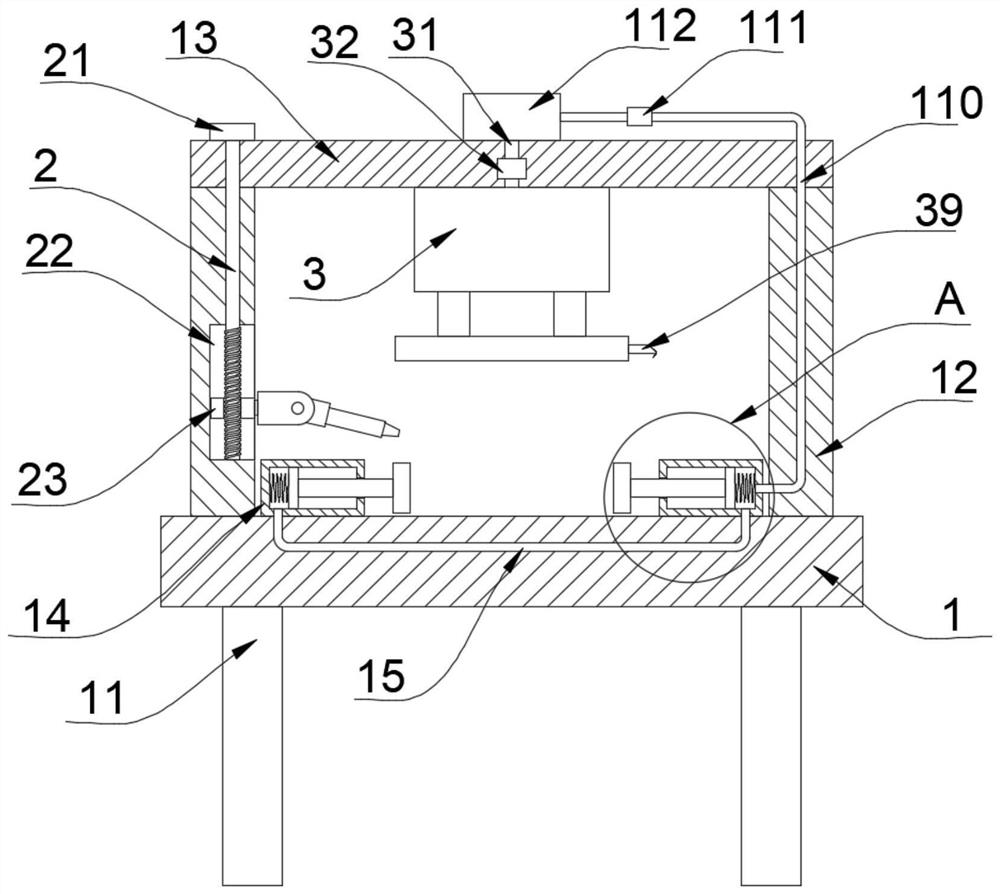

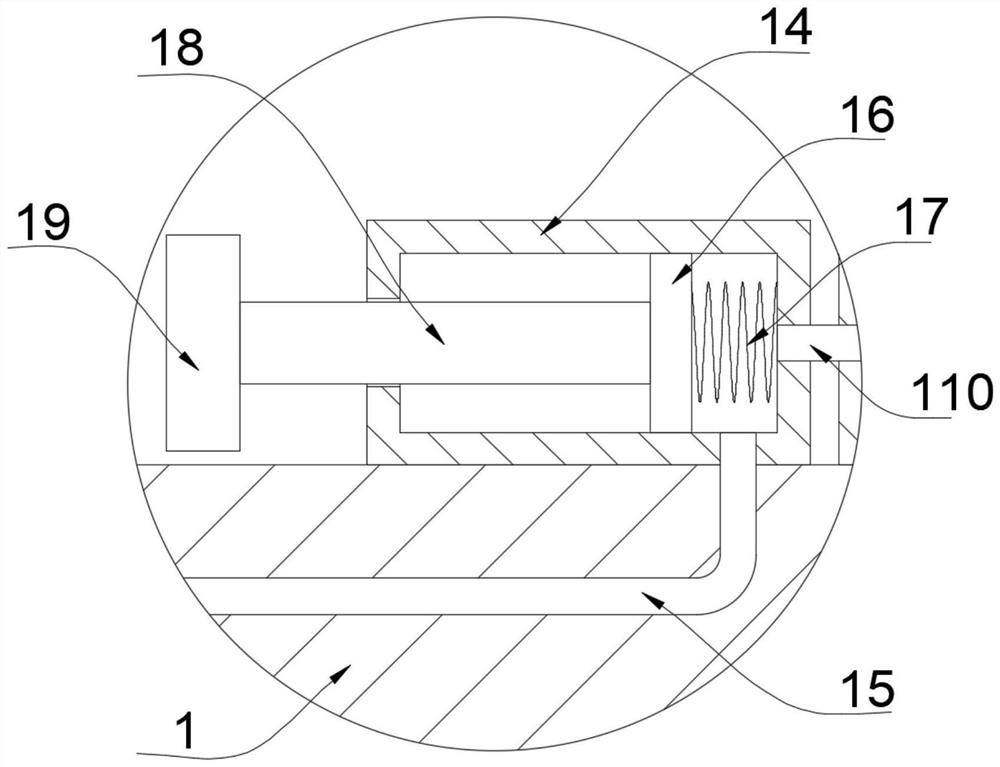

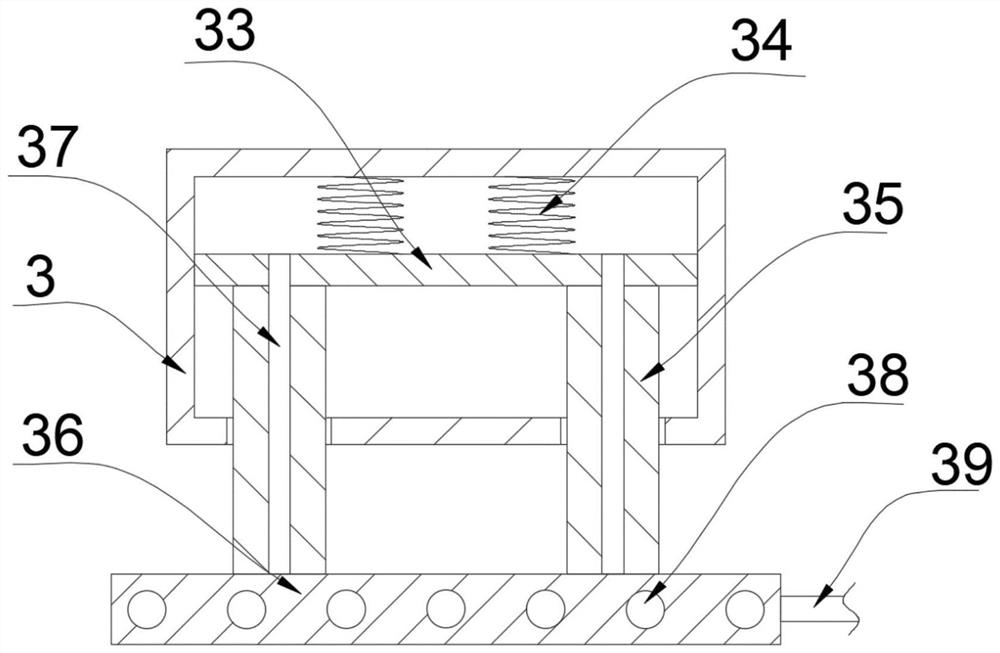

[0021] refer to Figure 1-4 , a device for heating materials based on a high-power laser, including a workbench 1, a fixing mechanism, which is used to fix the material to be processed, an adjustment mechanism, which is used to adjust the angle and height of the laser heating device, and a cooling mechanism, which It is used to rapidly cool the heated material. The fixing mechanism includes a pillar 11 fixedly connected to the bottom of the workbench 1. A bracket 12 is symmetrically fixedly connected to the top of the workbench 1. A crossbeam 13 is fixedly connected to the top of the bracket 12. The workbench 1 The upper part is fixedly connected with a fixed block 14, the fixed block 14 is a hollow structure, a first pipeline 15 is arranged inside the workbench 1, the inside of the fixed block 14 is connected through the first pipeline 15, and the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com