Feed ultrafine grinder

An ultra-fine pulverizer and feed technology, which is applied in the direction of grain processing, etc., can solve the problems of clogging of the pulverizing bin and overloading of the pulverizer, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

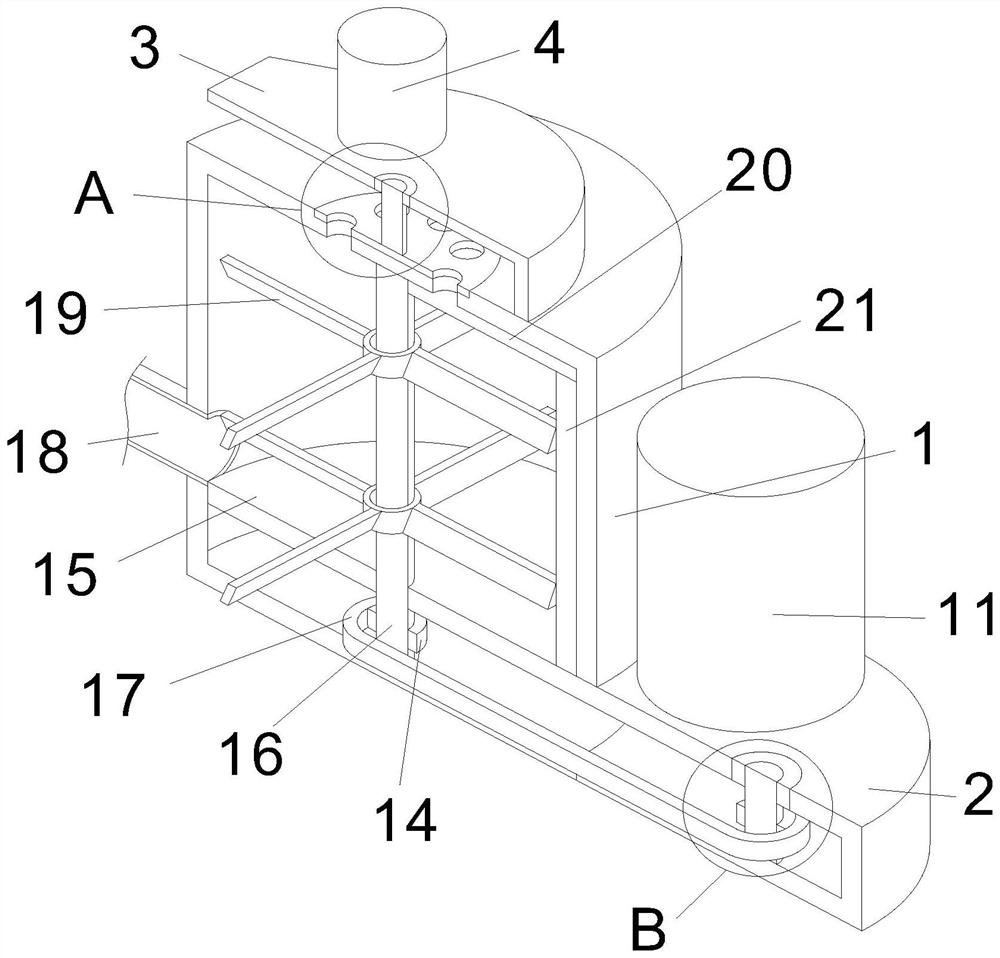

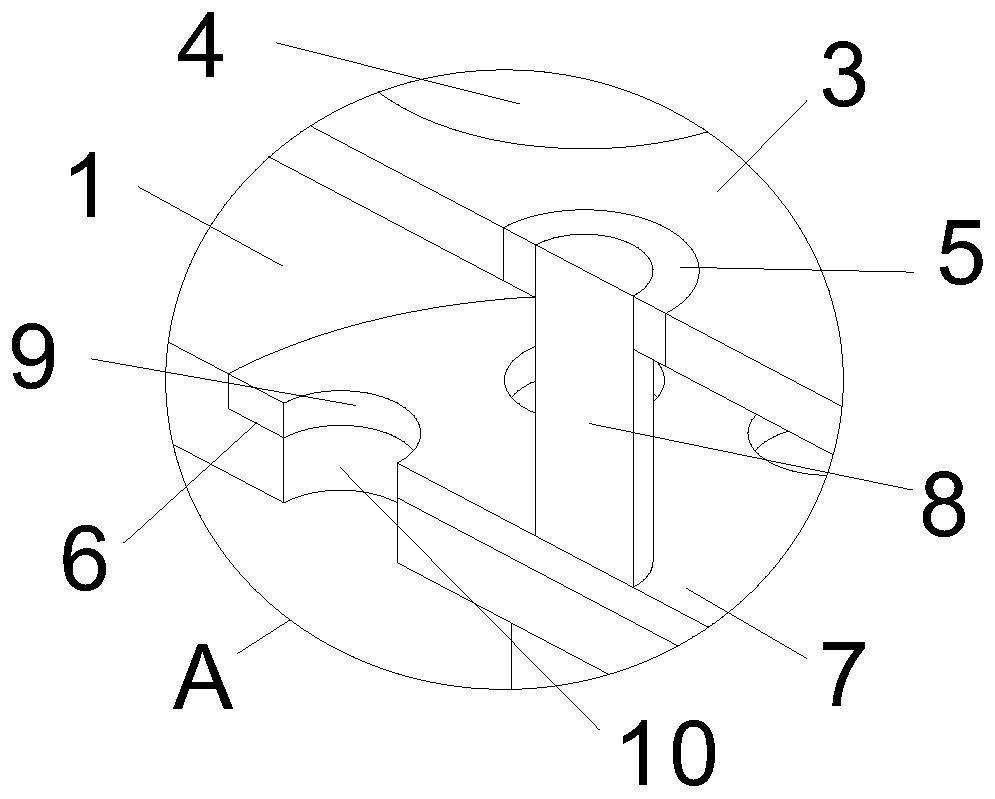

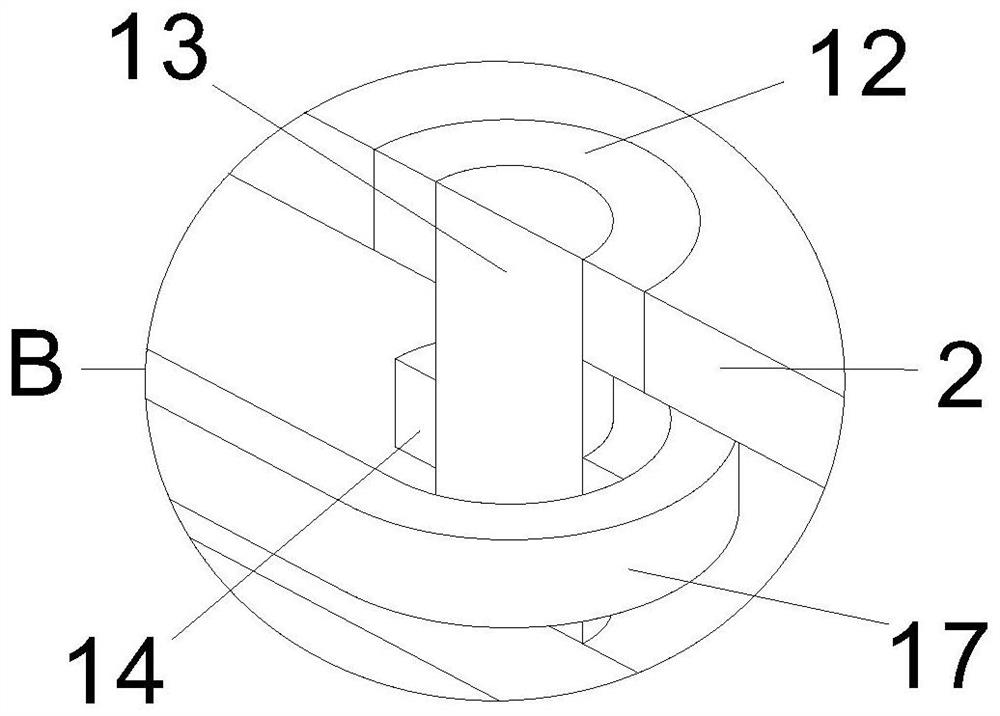

[0023] Embodiment: Feed superfine pulverizer, as figure 1 - image 3 As shown, it includes a crushing bin 1 and a transmission bin 2. The crushing bin 1 is a hollow cylindrical structure, and the transmission bin 2 is a hollow semicircle. , the top wall of the crushing bin 1 is fixedly equipped with the lower material bin 3, the lower material bin 3 is a hollow drop-shaped structure, the top wall of the lower material bin 3 is fixedly installed with the feeding motor 4, and the top wall of the lower material bin 3 corresponds to the feeding The position of the motor 4 is inlaid with an installation bearing 5, the installation bearing 5 is a ring structure, the top wall of the crushing bin 1 is provided with an installation groove 6, the installation groove 6 is a circular groove, and the inside of the installation groove 6 is provided with a blanking The plate 7, the blanking plate 7 is a circular plate, the inner ring of the mounting bearing 5 is fixedly installed with a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com