Rotary microfluidic device and method for controllably preparing monodisperse emulsion

A microfluidic device, monodisperse technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of high fluid control requirements, cumbersome construction process, complex device structure, etc., to achieve high surface tension, The effect of reducing the requirements of professional technology and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

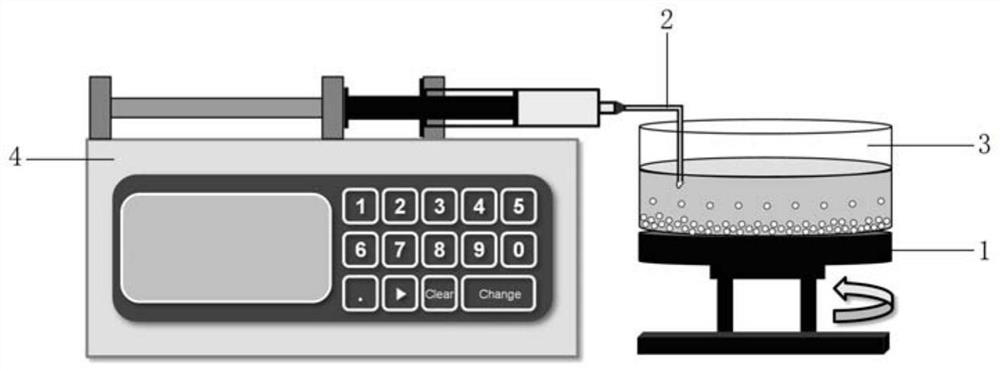

[0038] In this example, a rotary microfluidic device that can controlly prepare monodisperse emulsion is provided, and its structural schematic diagram is as follows figure 1 As shown, a rotating platform 1 , a syringe 2 , a collection container 3 and a syringe pump 4 are included.

[0039] The rotating platform 1 includes a motor and a horizontally arranged turntable, the turntable is circular, and the motor drives the turntable to rotate at a constant speed around the center of the turntable; the cross section of the collection container 3 is circular, specifically a glass petri dish with a diameter of 20 cm, and the collection container is fixed horizontally On the turntable, that is, the circular bottom surface of the petri dish is fixed horizontally on the turntable, and the center of the petri dish coincides with the center of the turntable; the motor drives the turntable to rotate at a constant speed, and then drives the collection container on the turntable and the cont...

Embodiment 2

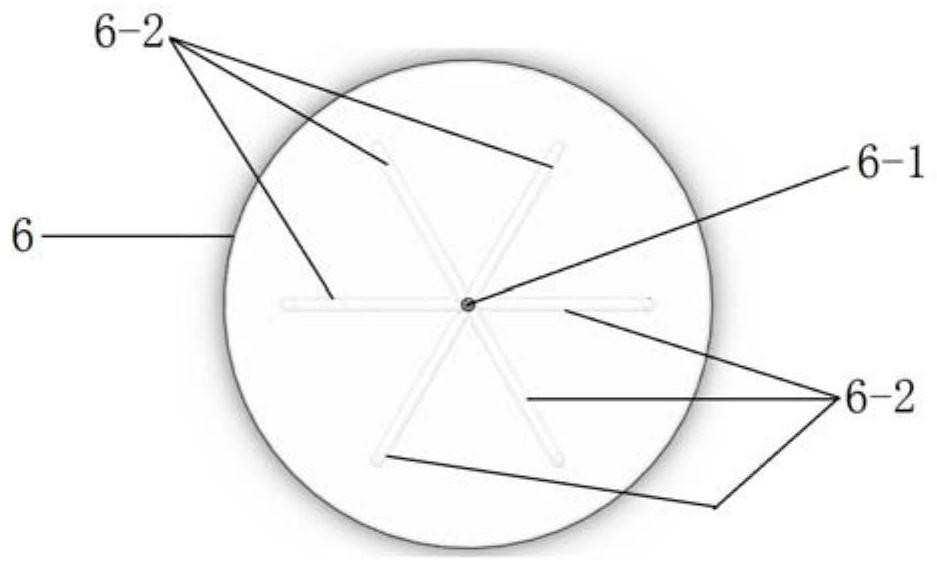

[0042] In this embodiment, a rotary microfluidic device for controllable preparation of monodisperse emulsion is provided, including a rotary platform 1 , a syringe 2 , a collection container 3 , a syringe pump 4 and a fluid distribution plate 6 .

[0043] The rotating platform 1 includes a motor and a horizontally arranged turntable, the turntable is circular, and the motor drives the turntable to rotate at a constant speed around the center of the turntable; the cross section of the collection container 3 is circular, specifically a glass petri dish with a diameter of 20 cm, and the collection container is fixed horizontally On the turntable, that is, the circular bottom surface of the petri dish is fixed horizontally on the turntable, and the center of the petri dish coincides with the center of the turntable; the motor drives the turntable to rotate at a constant speed, and then drives the collection container on the turntable and the continuous phase fluid in the collection...

Embodiment 3

[0047] In this embodiment, the preparation process of monodisperse water-in-oil (W / O) emulsion is taken as an example to illustrate the controllable preparation method of monodisperse emulsion provided by the present invention. The steps are as follows:

[0048] (1) Preparation of dispersed phase and continuous phase fluid

[0049] Deionized water was used as the dispersed phase fluid; T154 was dissolved in soybean oil to obtain the continuous phase fluid, and the concentration of T154 in the continuous phase fluid was 0.04g / mL.

[0050] (2) Preparation of monodisperse W / O emulsion

[0051] The rotary microfluidic device described in Example 1 is used for preparation, the continuous phase fluid is contained in a petri dish, the outlet of the injection tube is controlled to be located below the liquid level of the continuous phase fluid contained in the petri dish, and the outlet of the injection tube is in contact with the petri dish The distance between the centers of the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com