Bionic body surface tissue and step-by-step construction method thereof

A construction method and body surface technology, applied in prosthetics, medical science, bone implants, etc., can solve the problems of insufficient matrix and microstructure, insufficient mechanical properties, etc., to meet the needs of clinical applications, improve mechanical strength, get handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

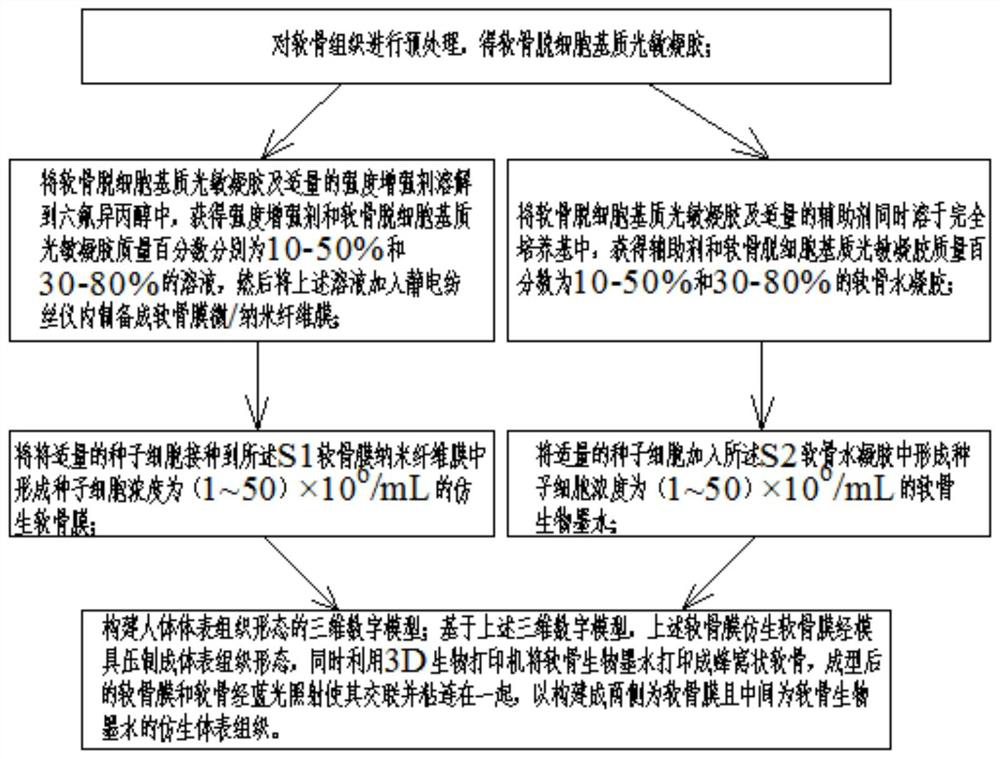

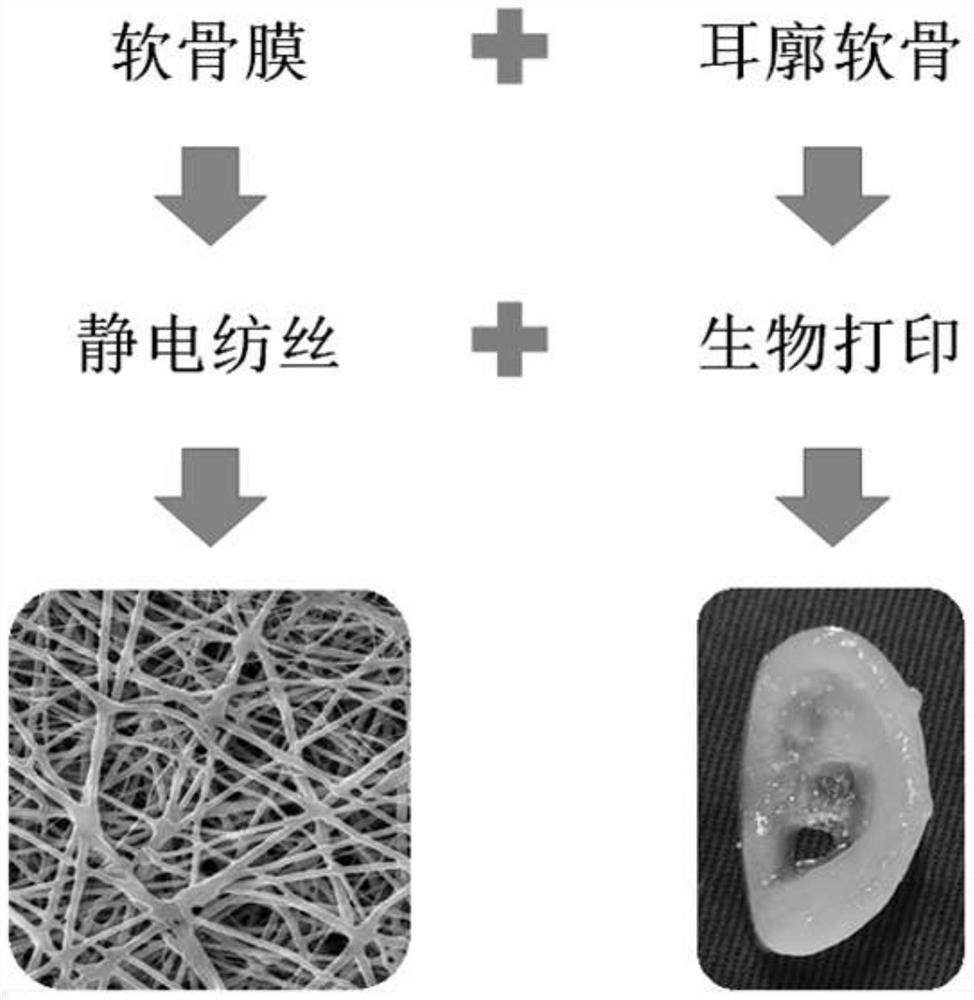

[0053] Such as Figure 1 to Figure 13 As shown, this embodiment provides a step-by-step construction method of bionic body surface tissue, including the following specific steps:

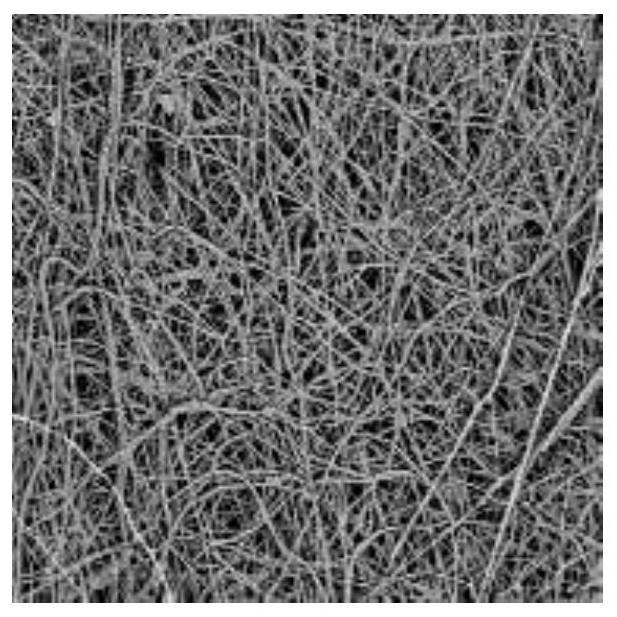

[0054] S1: The cartilage decellularized matrix photosensitive gel and an appropriate amount of strength enhancer are dissolved in hexafluoroisopropanol, and the mass percentages of the strength enhancer and cartilage decellularized matrix photosensitive gel are 10-50% and 30-80% respectively solution, and then add the above solution into the electrospinning apparatus to prepare a perichondrium micro / nano fiber membrane;

[0055] S2: Dissolving cartilage decellularized matrix photosensitive gel and appropriate amount of auxiliary agent in complete medium at the same time to obtain cartilage hydration with the mass percentage of auxiliary agent and cartilage acellular matrix photosensitive gel being 10-50% and 30-80% glue;

[0056] Among them, one or more components of basic fibroblast growth factor...

Embodiment 2

[0061] On the basis of Example 1, in this example, before S1, S0 is also included: pretreating the cartilage tissue to obtain a cartilage decellularized matrix photosensitive gel. Simple preparation process, providing biomimetic raw material cartilage acellular matrix photosensitive gel for perichondrium and cartilage bioink

Embodiment 3

[0063] On the basis of Example 2, in this example, the cartilage tissue in the S0 is one or more of ear cartilage, articular cartilage, costal cartilage, scapular cartilage, and meniscus. The method is convenient to obtain, and is beneficial to the preparation of bionic reconstructed body surface tissue.

[0064] It should be noted that the above-mentioned cartilage tissue is usually pig cartilage tissue, which can be purchased in the market and can be industrialized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com